INSTALLATION, USE AND MAINTENANCE

GBA-GBP-CBE-MBE SERIES

72

6.4 Adjusting and regulating

6.4.1 Adjusting the rotation brake of the crane arm

REMAINING RISKS IF ON THE CRANE DURING THE ADJUSTMENT OF THE BRAKE

DANGER / RISK

BAN / WARNING

OBLIGATION / PREVENTION

Risk of crushing

in case of

contact with the rotation arm

when adjustments of the brake

are being made

Warning!

Exposure to moving

parts can cause danger.

• Adjustments of the brake must

be carried out by qualified

maintenance staff.

• Use of protective gloves and, if

necessary, safety harnesses.

•

The brake of the jib crane must be adjusted so as to guarantee the stability of the arm

in any of its positions with a maximum load.

•

The braking is mechanical and is ensured by two pushed clutch plates which with

adjusting screws work on a pressure plate, in contact with the rotation tube of the

arm.

•

The clutch plates, which are asbestos-free, are subject to wear in relation to the

intensity of service and when, after a period of use, there is a tendency of the arm to

take up preferred positions putting itself in different positions to those required when

the rotation action has not happened, adjustment must be made.

To adjust the brake of the arm of the jib crane proceed as follows:

WARNING! When this operation is carried out at a height, on a scaffolding or

other mobile equipment, the use of safety harnesses is obligatory.

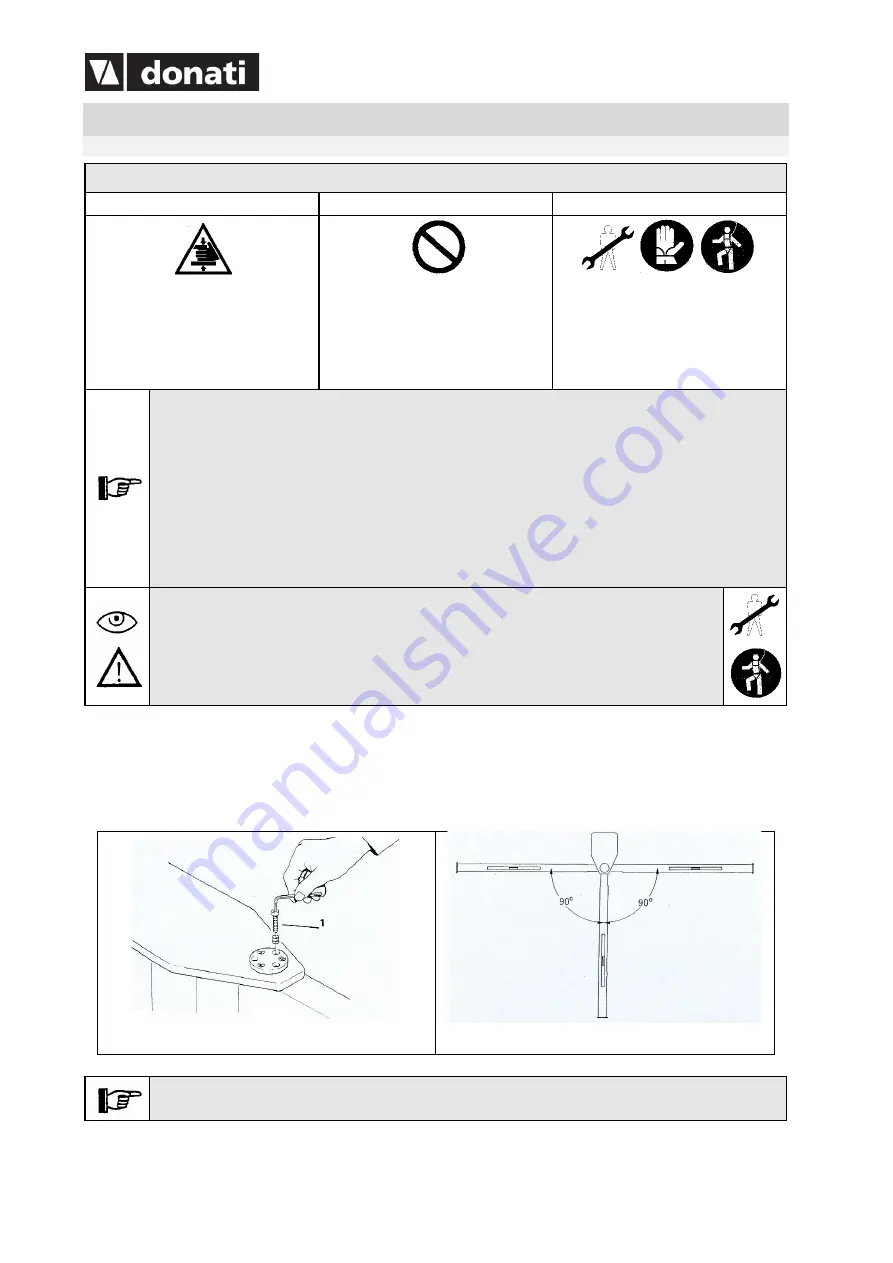

1. Regulate the slidability of the rotation of the arm, using the braking system by means of the adjusster

screws

1

, until you obtain the required flexing sensitivity (fig. 100).

2. Carry out the check of planarity of the arm with the help of a level. Carry out such a check rotating the

arm by 90° to the left and to the right (fig. 101).

fig. 100

fig. 101

If the adjusatment of the brake has been made several times and after the last adjustment

the stability of the arm is not guaranteed, replace the clutch plates.