INSTALLATION, USE AND MAINTENANCE

GBA-GBP-CBE-MBE SERIES

22

3.5 Safety devices and instructions

3.5.1 Control devices

Jib cranes, in both GBA-CBE pillar-mounted version and GBP-MBE wall-mounted version can be controlled

in the following ways:

1. If equipped with an

electric hoist

and push trolley

movements are activated:

•

from a pushbutton panel

with “lift and lower” buttons to control the

lifting

movement.

•

by pushing the load

to control the

traverse

trolley.

2. If equipped with an

electric hoist

and electric traverse trolley

movements are activated:

•

from a pushbutton panel

with “lift and lower” buttons to control the

lifting

movement.

•

from a pushbutton panel

with “right and left” buttons to control the

traverse

movement.

3. If equipped with a

manual hoist

and trolley

movements are activated:

•

by mechanical activation

of the hoist chain for the

lifting

movement.

•

by pushing the load

to control the

traverse

trolley.

4. The

rotation movement of the jib crane arm

, both clockwise and anticlockwise, is activated manually

with P&T

pushing the load

or electrically from the pushbutton panel.

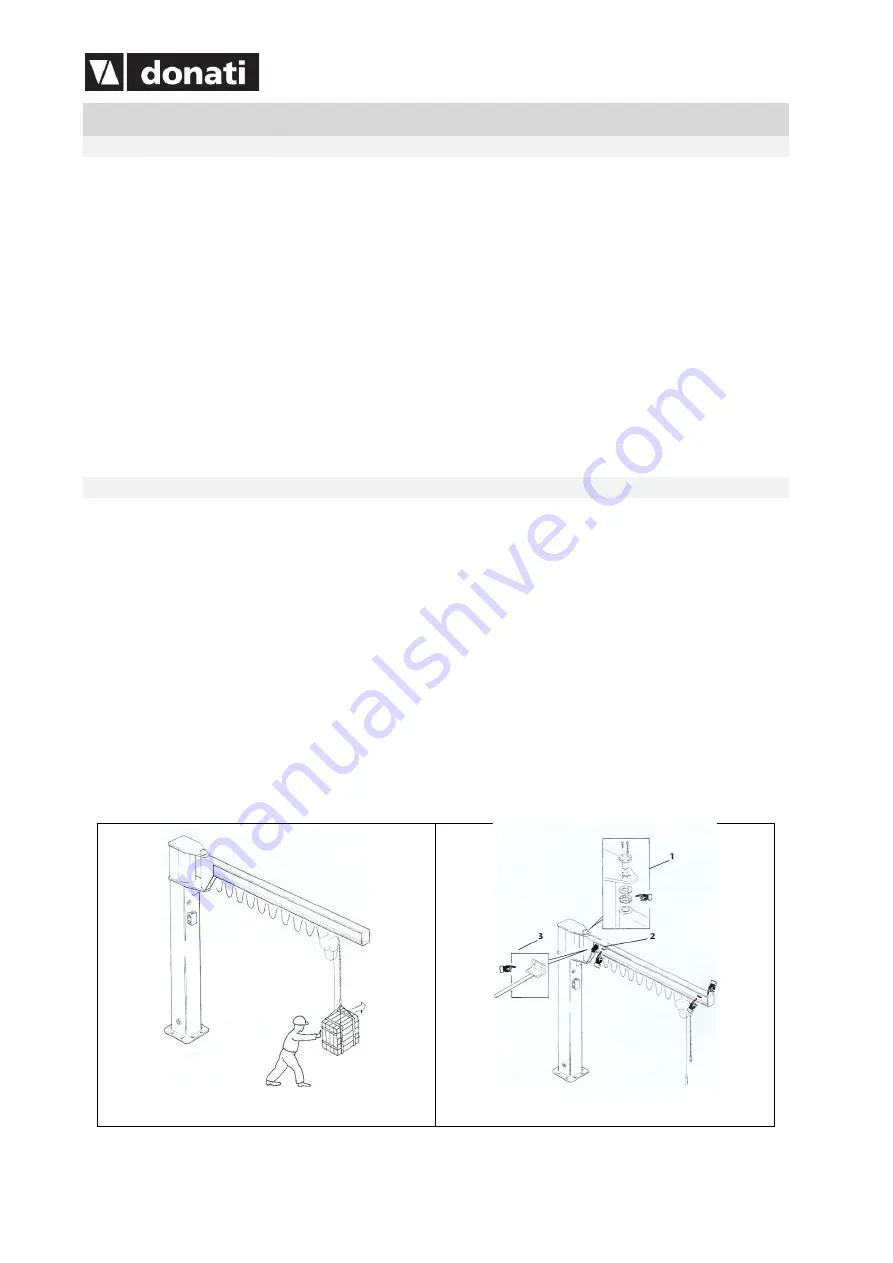

3.5.2 Safety and emergency devices for GBA- GBP

The

manually rotated jib cranes

in the

GBA

pillar-mounted version and the

GBP

wall-mounted version,

are fitted with the following safety and emergency devices (fig. 11):

SEE ALSO ASSEMBLY RULES OF S-TYPE

ARM

1.

Rotating brake,

by friction, which allows the regulation of the arm’s rotating force and ensures the

stability of positioning.

2.

Trolley-end limit switches,

mechanical catches which limit the maximum run of the trolley along

the arm’s girder.

3.

Mechanical limit switch actuators

(in the case of the crane with electric trolley), limit switch striker

plates of the trolley’s electrical microswitches.

4.

Limit switches for the arm’s ends supplied on request,

mechanical catches which limit the

maximum rotation of the arm.

5.

Anti-collision device, available on request,

to avoid the telescoping of two or more arms which,

operating in the same area, can interfere with each other; or to avoid the collision of the arm with

surrounding structures.

fig. 10

fig. 11