INSTALLATION, USE AND MAINTENANCE

GBA-GBP-CBE-MBE SERIES

28

4.2.4 Removal of the packaging and/or checking of the crane parts

•

In the case of packaged parcels, open the packaging and extract the various parts using suitable

equipment chosen in relation to their weight and grip points.

•

Check the conditions of all of the material of the supply and make sure no parts and/or accessories

are missing. Notify the manufacturer immediately if anything is damaged or missing.

•

If the material is going to be stored follow the instructions in paragraph

4.5.1 “Decommissioning

•

".

•

Check the conditions of all the crane parts and in particular check that:

o

the columns and arms have not been crushed, deformed, bent or have any

broken parts.

o

there is no damage to the components of the electrical system (if included)

•

Dispose of the packaging as required by regional waste disposal laws based on

the nature of the waste (wood, plastic, cardboard), after sorting it.

4.3 Jib crane installation

4.3.1 Installer duties and responsibilities

•

Installation of the jib crane, due to the importance of the operations,

may cause, if not correctly performed, serious risks for the safety of

exposed persons both in the assembly phase and subsequent crane

use phase. Therefore, if not performed by the manufacturer it must be

entrusted to installers specialised in the assembly of industrial plants.

•

Lifting and overhead placement of crane parts must be performed

by installers equipped with:

o

adequate and suitable personal protection equipment

(e.g.

helmet, gloves, safety belt, etc.)

o

equipment

(e.g.: forklift, scaffolding, etc.)

adequate for the purpose.

•

And after a careful evaluation of the following parameters:

o

environmental characteristics of the work site

(e.g.: walk on surfaces,

etc.)

o

height of the work surface compared to the loading surface

o

dimensions and weight of the parts to install

o

spaces available for handling the parts to install

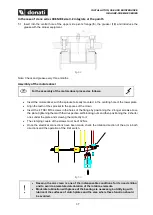

Before carrying out the assembly of the parts and installation of the jib crane,

the installer must make sure that the crane specifications are in compliance

with what was requested and the intended use and in particular:

1) The crane capacity is

compared to the loads to lift.

2) The specifications of the anchoring structures (plinth, floor, wall, pillar, etc.) have been

“Declared

suitable”

by the customer or expert technicians appointed by the customer.

3) The specifications of the lifting unit (trolley/hoist), if not part of the supply, are compatible with those of

the jib crane in relation to: (fig. 17)

a)

Hoist capacity:

must be

compared to the jib crane capacity.

b)

Weight of the trolley/hoist:

must be

compared to the maximum weights.

c)

Lift/traverse speed

must be

compared to the maximum ones allowed.

d)

Overall dimensions of the trolley/hoist:

must be

compared to the maximum ones allowed.

e)

Reactions on the trolley wheels:

must be

compared to the maximum ones allowed.