INSTALLATION, USE AND MAINTENANCE

GBA-GBP-CBE-MBE SERIES

29

fig. 17

Following the jib crane installation activities, the installer must:

1. Conduct the

“Commissioning”

, activities as described in paragraph 4.4;

2.

Draft the “

Acceptance test

” report and approve the jib crane “

Suitable for use

”;

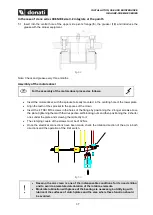

4.3.2 Preparation of the installation site

To allow the jib crane installation, first perform the following

operations:

1) Verify the presence of the suitable/adequate declaration of the support/anchoring structures;

2) Verify the absence of clear defects of the support/anchoring structures (fig. 18);

3) Verify the suitability of the manoeuvre (rotation) spaces for the jib crane, especially if operating in areas

where other cranes or operating machines are present (fig. 19);

4) Verify the suitability and correct operation of the mains: (fig. 20)

a) correspondence of the line voltage with the voltage required for the motors

b) presence and suitability of the electrical line switch/circuit breaker;

c) adequacy of the cable cross section of the electrical line;

d) presence and suitability of the earthing system;

5) In case of a jib crane with an arm with a section bar of laminated girder (H- or T-type), check the width

of the flange of the girder which must correspond to that intended for the trolley wheels (fig. 21).

6) Prepare the masses for the

dynamic tests

equal to:

rated capacity x 1.1

7) Prepare the masses for the

static tests

equal to:

rated capacity x 1.25

8) Prepare the equipment for slinging and lifting of the masses for the load tests

9) Verify the presence of signs warning of the risks due to handling with the crane.

fig. 18

fig. 19