INSTALLATION, USE AND MAINTENANCE

GBA-GBP-CBE-MBE SERIES

46

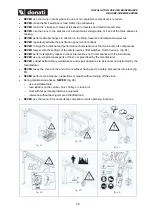

4.4.1 Acceptance test of the jib crane - Suitability for use

•

The jib crane is put on the market considering the acceptance tests conducted at

the manufacturer on similar prototypes subjected to testing of their suitability on

the structural parts (columns, shelves, arms, etc.).

•

The manufacturer performs a test on the manufacturing and guarantees the

constant quality and the compliance to the tested prototypes of all the parts of the

jib crane.

•

The acceptance test procedure, described below, refers to verification of the

functional and performance compliance of the jib crane installed in its place of

use, complete with all its parts (anchors, structure, lifting unit, lifting accessories,

etc.).

•

The acceptance test of the installed crane is the responsibility of the user and

must be conducted by the same specialised personnel (Installer) who performed

the assembly, scrupulously following the instructions of this manual.

•

The installer must perform the acceptance test and fill out all parts of the

“Acceptance test report” and draft the “Suitable for use” certificate contained in

the

“Test logbook” attached, when included, to this publication.

After having performed the “no load” operating tests, perform the dynamic tests; these tests are performed

with weights corresponding to the capacity of the crane plate plus an overload factor of 1.1 (load equal to

110% of rated load). The static tests are performed with an overload factor of 1.25 (load equal to 125% of

the rated load).

All the tests must be performed when there is no wind

To perform the acceptance test of the jib crane, proceed as follows:

No load tests:

•

activate the line switch/circuit breaker

•

put the emergency stop button in the “start consensus” position

•

press the “start/alarm” button (if available)

•

check the lift function by pressing the lift/lower buttons

•

check the travel function by pressing the right/left buttons, if in electric trolley version

•

if there are two speed movements check its operation

•

check swinging of the arm using manual/electric rotation

•

check the operation of the limit switches on all movements and/or the friction device, when available

Dynamic test:

•

prepare adequate weights for the load tests equal to

rated capacity x 1.1

and suitable equipment for

slinging and lifting the load

•

sling the load being careful to position the hook vertically to avoid oblique pulling

•

slowly tension the sling to avoid tugging, perform the load tests using the “slow” speed if available

•

slowly lift the load and check that this occurs without problems and that no anomalous noise is heard,

or clear deformation or giving way of the crane structure, support structures and/or anchorages

•

repeat the test at maximum speed, if available, performing the previous tests

•

check the operation of the lift/lower electric limit switches, when installed, and/or any friction device