INSTALLATION, USE AND MAINTENANCE

GBA-GBP-CBE-MBE SERIES

48

•

If during the entire storage period, these values do not comply with what is indicated, it will be

necessary to perform some preliminary tests before putting the crane into service (see paragraph 4.5.2

"Ripristino dopo stoccaggio")

•

If the temperature goes above or drops below the indicated values and the relative humidity is greater

than 80% prepare protection packaging for the parcels with sacks and hygroscopic salts.

•

Storage in outdoor areas requires:

o

wedges to lift off the floor for all parcels without pallet

o

protect all parcels with sacks and hygroscopic salts

o

if the crane has been built to operate outdoors the metal work parts do not require particular

protections; on the contrary the parts machined on machine tool (machined surfaces, wheels,

pins, etc.) must be protected with antioxidant products (transparent paints, grease, etc.).

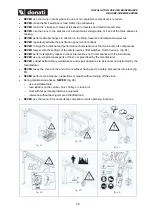

4.5.2 Resetting after storage

Before putting a jib crane back into operation after a long period of

storage, it is necessary to perform the following operations:

•

Structure:

eliminate traces of lubrication from the structure and the trolley beam

go over the hole threading and eliminate any grease residue

cleaning the matching surfaces used for assembly

repair any structural damage (scratched surfaces, crumbling paint, etc.)

•

Mechanisms:

check for any leaks and top up lubricant levels, if necessary

check the correct fixing of the mechanisms to the structure

eliminate traces of oxidation from the accessory sliding parts of the control parts

lubricate the bearings and unpainted mechanical parts (shafts, pins, etc.)

eliminate any water residue in the concave parts

•

Electrical equipment:

eliminate any condensation from the motors and connector blocks; dry with jets of air

check the conditions and operation of the brakes

accurately clean the surfaces of the brakes eliminating any traces of moisture, lubricants and paints

check the conditions and operation of the limit switches

check the conditions of the electrical parts and components

dry the contactor contacts

accurately clean the closing surfaces and the threaded holes of all containers

check the movement of the electric lines with festoons

carefully check the operation of the control pushbutton panel