INSTALLATION, USE AND MAINTENANCE

GBA-GBP-CBE-MBE SERIES

56

5.5

Criteri e precauzioni d’uso

•

The correct use of the jib crane makes it possible to fully use the

performance that is able to provide in completely safe conditions.

•

This potential is only guaranteed by scrupulously following the instructions

below:

•

ALWAYS

follow the indications and instructions contained in the installation and user manuals and

check the conditions of the crane components and parts.

•

ALWAYS

comply with the instructions and warning shown on the machine; the warning plates on the

crane and the manoeuvre areas are accident prevention warnings and they must always be perfectly

legible.

•

ALWAYS

make sure that the crane works in an environment protected from inclement weather (rain,

wind, snow, etc.) or, if outdoors, that it is equipped with suitable guards.

•

ALWAYS

check the compliance of the crane performance in relation to its intended service (duty

cycles - intermittence - use time - load to handle) .

•

ALWAYS

check the solidity and adequacy of the structures (columns, foundations) which support the

jib crane (fig. 82).

•

ALWAYS

make sure the maintenance conditions of the crane are adequate (cleaning and lubrication)

and of its main components (hook, chains, pushbutton panel, limit switches, gear motors, wheels,

brakes, etc.).

•

ALWAYS

check the correspondence of trolley and hoist movements.

•

ALWAYS

test the operation of the emergency stop button.

•

ALWAYS

and constantly check the efficiency of the brakes, limit switches and electrical system.

•

ALWAYS

check the conditions of the chain, block, hook and pushbutton panel.

•

ALWAYS

check that the hook is not worn, damaged or missing its spring catch.

•

ALWAYS

check the suitability and efficiency of the slings (ropes, chains, bands, etc.).

•

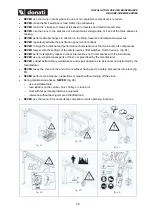

ALWAYS

check that the track for movement of the trolley, is installed at a height which does not allow

the operator to interfere with the shape of the trolley hoist and/or its moving parts. If this is not possible

install appropriate guards or signs located in the risk area (fig. 83).

•

ALWAYS

act on the load by pushing it during manual handling and avoid pulling it towards yourself

•

ALWAYS

make sure to have centred the lifting unit (hoist and hook), on the perpendicular axis of the

load before performing the slinging and handling of the load.

•

ALWAYS

correctly secure the slings of the load to the lifting hook and tension the slings with slow and

safe manoeuvres.

•

ALWAYS

work in the best lighting conditions of the area and visibility of the load.

•

ALWAYS

ensure, before any manoeuvres that arm rotation is free from obstacles and that the load

does not encounter obstacles during lifting, traverse and rotation

•

ALWAYS

work outside the manoeuvre range of the lifted load.

•

ALWAYS

activate the various movements avoiding the use of control impulses in rapid succession.

•

ALWAYS

avoid combining movements by activating the lift and traverse buttons at the same time and

being careful not to generate swaying of the load.

•

ALWAYS

use the “slow” speeds for approach and positioning operation (fig. 86).

•

ALWAYS

position the crane arm, load hook and pushbutton panel at the end of working in a manner

that they do not constitute elements of a collision risk (fig. 87).

•

ALWAYS

press the red emergency stop button on the pushbutton panel and disable the crane general

switch before leaving the manoeuvre position.

•

ALWAYS

turn off the machine voltage for inspections, repairs and routine maintenance operations.