INSTALLATION, USE AND MAINTENANCE

GBA-GBP-CBE-MBE SERIES

62

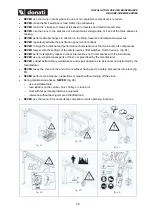

6.2 Qualification of personnel assigned to maintenance

To be able to adequately perform maintenance of the jib crane, the personnel assigned to maintenance

must:

•

know the current laws related to accident prevention during the work performed on the machines

with motor transmission and be able to apply them

•

have read and understood chapter 3 - "SAFETY AND ACCIDENT PREVENTION"

•

know how to use and consult this documentation

•

be interested in the machine operation

•

notice any operating irregularity and take the necessary measures if needed

The professional figures in charge and authorised to perform crane maintenance are:

Operator assigned to use of the jib crane

•

Typical maintenance activities:

Testing of correct operation of the jib crane. Collaboration with the personnel assigned to routine

and/or extraordinary maintenance, after prompt notification of the same if anomalies are

discovered.

cleaning and lubrication of the crane parts (hoist) with which they are normally in contact

(pushbutton panel and hook) and performance of simply performed maintenance activities which

do not require overhead interventions (e.g. hook thrust bearing lubrication).

•

Required technical knowledge:

knowledge of the functions and use of the jib crane

knowledge of the lubricant used in the crane and hoist and the hazards connected with their use

•

Required qualification:

suitable for work in relation to the specific operating and environmental characteristics

Mechanical maintenance personnel

•

Typical maintenance activities:

mechanical adjustment of brake and mechanism clearances.

testing of performance of movements and mechanical adjustment of safety devices

checking of mechanical clearances and component (chain, hook, etc.) wear

replacement of worn components (chain, hook, chain guide, pulleys) through the use of this

publication.

routine maintenance of the mechanical units after replacement of parts with original spares

•

Required technical knowledge:

good knowledge of the mechanical lifting and manual and motor handling systems

good knowledge of the safety devices used in the hoist (limit switch, brakes, load limiter, clutch,

etc.)

elementary knowledge of moderately difficult electrical setting and control techniques (limit switch

adjustment, fuse replacement, motor connections, etc.)