INSTALLATION, USE AND MAINTENANCE

GBA-GBP-CBE-MBE SERIES

67

6.3.2 Frequency and deadlines for maintenance interventions

The frequency of the following operations refers to a jib crane used in normal operating conditions and are

valid up to service group M5 (standard ISO 4301/86) or 2m (FEM 9,511 rule). If the use of the jib crane is

normal and correct for a daily 8 hour shift, the following overhaul may be performed after a use period of

approximately 10 years (FEM 9,755 - S.W.P. rule) If use is over various shifts, the maintenance periods

need to be reduced proportionately.

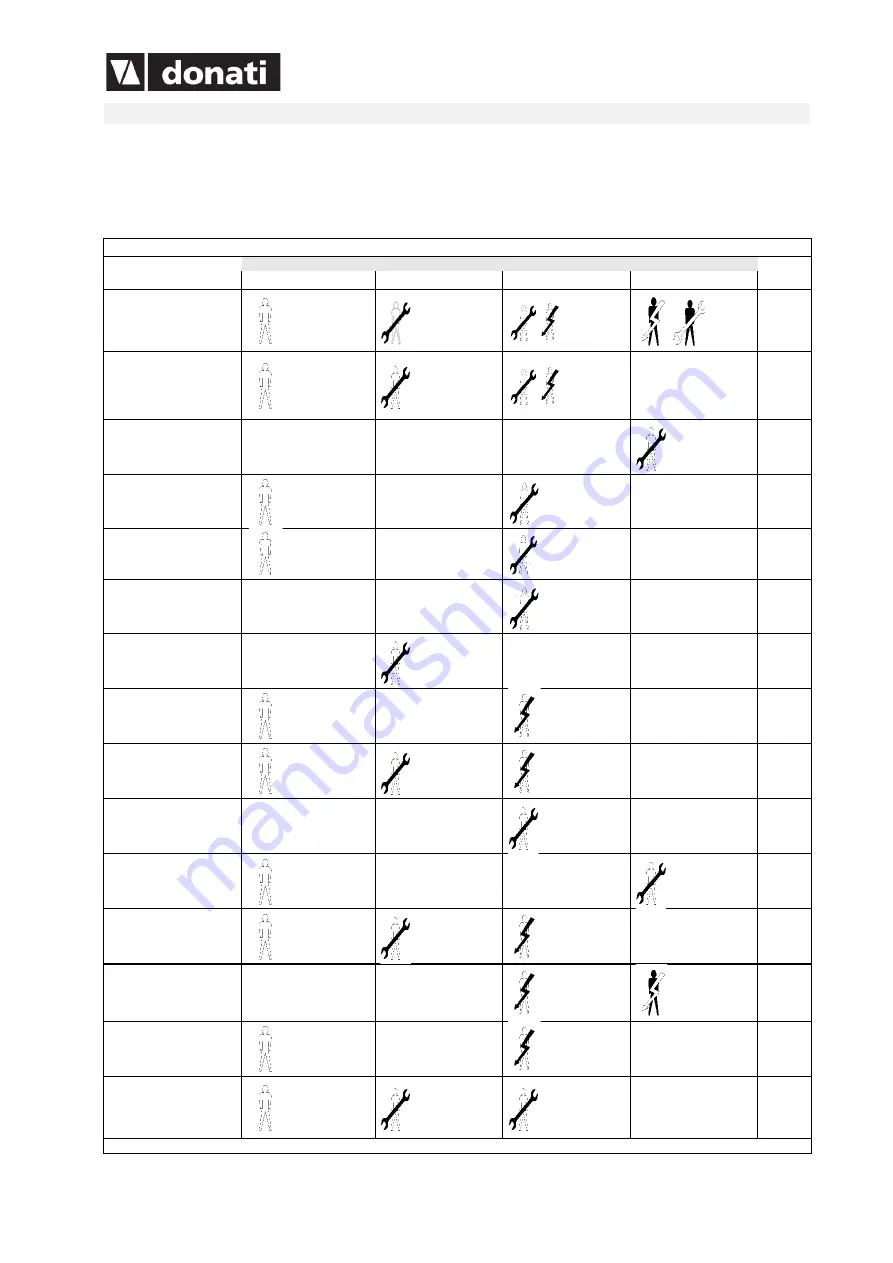

Table of periodic checking and maintenance operations

Subject of the check

Periodic checks

Useful

notes

Daily

Monthly

Quarterly

Annual

Checks

Inspections -

Acceptance tests

General visual

checks

Correct

operation

General visual

inspections

Check

wear

Annual

accepta

nce test

pag. 43

Warnings and

pictograms, Signs

and plates

Legibility of

warnings and

pictograms,

signs and

plates

Inspections of

conditions

and cleaning

of plates and

signs

Check

suitability

pag. 23

Structural elements

Welding - Pins Bolted

connections

Check wear and

efficiency Check

bolted/welded

pag. 66

Chain

Anchoring parts

Visual

inspection

Check wear

and efficiency

Hoist

manual

Lifting hook

Visual

inspection and

check spring

catch

Check wear

and efficiency

Hoist

manual

Loading nut Chain

guide Block return

Check wear

and efficiency

Hoist

manual

Lifting gear motor

Traverse gear motor

Rotation gear motor

Noise test

Hoist

manual

Lifting motor Traverse

motor Rotation motor

Check correct

operation

Load test

Hoist

manual

Lifting brake Traverse

brake Rotation brake

Check correct

operation

Load tests

Check wear

Load tests

Check wear

Hoist

manual

and

pag. 68

Wheels and pinions

Guide roller Rotation

bearings

Check wear

Hoist

manual

and

pag. 67

Trolley buffers Jib

anti-collision

Visual

inspection

Check wear and

efficiency

Hoist

manual

and

pag. 67

Electrical system

Pushbutton panel and

cable

Check correct

operation

Inspection of

external

pushbutton

panel/cable

Check wear

and efficiency

Hoist

manual

and

pag. 68

Load limiter Clutch

device

Load test

Check the

calibration

Hoist

manual

Lifting limit switch

Traverse limit switch

Check correct

operation

Load tests

Check wear

and efficiency

Hoist

manual

Cleaning and

lubrication

Check correct

cleaning and

lubrication

conditions

General

lubrication

inspection

Check for

chain, hook and

mechanism

lubrication

leaks

Hoist

manual

and

pag. 68

N.B.: The following operations must be noted in the specific control booklet (See chapter 8)