MAN05MGO5

INSTRUCTIONS JIB CRANE SERIES GBA - GBP

13

Size of jib crane

R

S

T

U

6

Z

Counterplate code

Counterplate measurements (mm)

Counterplate weight (kg)

Maximum tiliting momentum allowed (kNm)

4YPEOFCONCRETEOFTHEFLOOR

Class Rck minimum (kg/cm2)

Type of chemical bolts

ES(),4)(65WITHTHREADEDBARS(),4)(!3

Minimum thickness of the block of the floor

(mm)

Diameter of the hole in the floor

(mm)

Depth of the hole in the concrete of the floor

(mm)

Clamping couples of the anchors

(),4)

(Nm)

Minimum resistance to traction of one anchor

(kN)

GBA1R0PS0

500

-

15

-

340

-

-

4x15

26

10.3

250

M12

140

14

110

50

18

GBA1S0PS0

500

-

20

-

400

-

-

4x19

31

16

250

M16

170

18

125

100

26

GBA1T0PS0

700

380

15

20

250

-

-

8x19

66

30

250

M16

170

18

125

100

26

GBA1U0PS0

700

475

20

25

300

-

-

8x25

95

56

250

M20

220

24

170

160

38

'"!603

1000

555

20

30

300

300

120

20x25

190

107

250

M20

220

24

170

160

38

GBA1Z0PS0

1200

660

20

40

370

380

185

20x25

307

163.5

250

M20

220

24

170

160

38

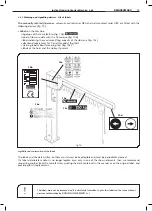

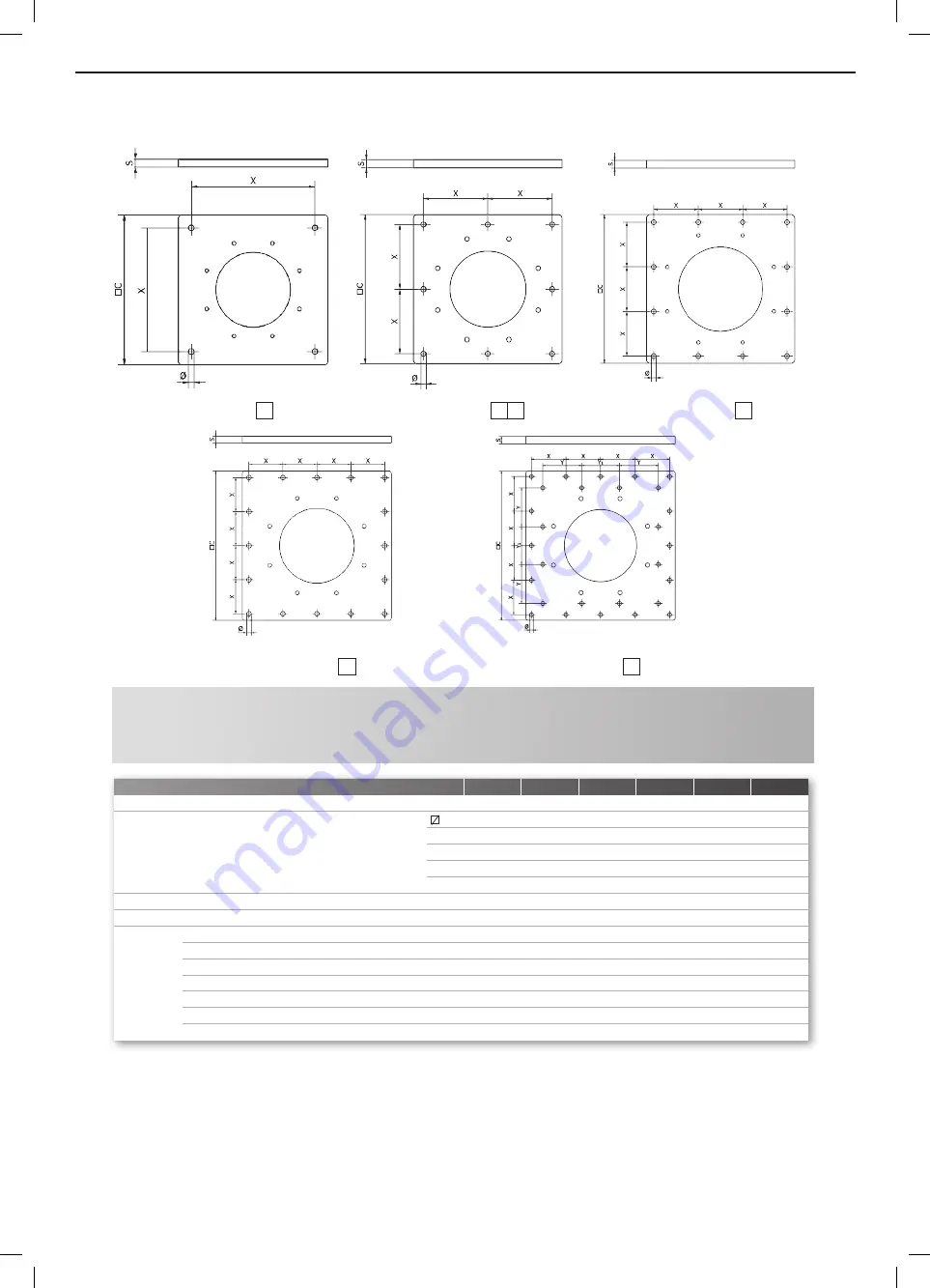

C

C1

S

S0

X

Y

Z

Nr x Ø

Mf

Fixing

characteristics

For the clamping couples of the bolts between the column and the counterplate, see the relative clamping couples for the logbolts page 12.

4OENSURETHETIGHTNESSOFTHEFIXINGWITHTHERESIN(),4)(65OPERATEASFOLLOWS

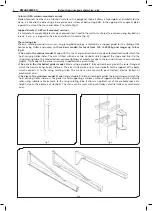

a) Drill holes in the concrete surface by using coring drill or as a drilling template the same counter.

b) Thoroughly clean the hole with a jet of air and a brush.

c) Place the tube into the hole and insert a steel bar through a rotary percussive drill supplied with the entrance to

bars and stem drag.

d) After laying, the workweek in which the bars must be placed and the time when we must not intervene in order

to allow complete curing, are specified in the instruction booklet in each tin of resin.

Counterplat es for fixing to the floor with chemical bolts of the GBA column-mounted cranes

Thefixingofthecolumnusingchemicalbolts,needsascrupulouscheckofsuitabilityinrelationto

thetypeofsupportflooring.

Thesuitabilitychecksaretheresponsibilityoftheuserandmustbecarriedoutbyexpert,qualified

technicianswhowillevaluatethefeasibilityandformallyassumetherelativeresponsibilities.

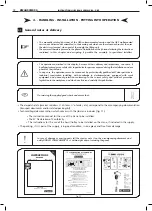

KMAN05MG05

!

The fixing of the column using chemical bolts, needs a scrupulous check of suitability in relation to the type

of support flooring.The suitability checks are the responsibility of the user and must be carried out by expert,

qualified technicians who will evaluate the feasibility and formally undertake the relative responsibilities.

Counterplates for fixing to the floor with chemical bolts of

the GBA/CBB/CBE column-mounted cranes

SIZE

R

S

T

U

V

Z

Counterplate code

GBA1R0PS5 GBA1S0PS5 GBA1T0PS5 GBA1U0PS5 GBA1V0PS5 GBA1Z0PS5

Counterplate dimensions (mm)

C

400

450

500

600

800

950

S

20

25

25

30

35

45

x

330

195

220

180

182

220

y / y1

-

-

-

-

-

240/248

Nr x Ø

4x15

8x15

8x19

12x19

16x25

28x25

Counterplate weight (kg)

20

31

39

63

139

254

Maximum tilting movement allowed (kNm)

Mf

11,8

20,7

31,2

56,7

107,3

164

Fixing

characteristics

Type of concrete of the floor: Class Rck minimum (kg/cm2)

C250

C250

C250

C250

C250

C250

Type of chemical bolts (e.g.: HILTI HVU with threaded bars HILTI HAS)

M12

M12

M16

M16

M20

M20

Minimum thickness of floor block (mm)

140

140

170

170

220

220

Diameter of hole in the floor (mm)

14

14

18

18

24

24

Depth of the hole of the concrete in the floor (mm)

110

110

125

125

170

170

Clamping torques of the bolts (Nm)

40

40

80

80

150

150

Project resistance of traction of one bolt (kN)

25,3

25,3

40

40

74,6

74,6

Nr8 Chemical bolts

Nr16 Chemical bolts

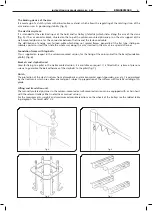

COUNTERPLATES

V

Nr28 Chemical bolts

COUNTERPLATES

Z

Nr4 Chemical bolts

COUNTERPLATES

R

COUNTERPLATES

S

T

Nr12 Chemical bolts

COUNTERPLATES

U

To ensure the tightness of the fixing with the resin HILTI HVU operate as follows:

a) Drill holes in the concrete surface by using coring drill or as a drilling template the same counter.

b) Thoroughly clean the hole with a jet of air and a brush.

c) Place the tube into the hole and insert a steel bar through a rotary percussive drill supplied with the entrance to

bars and stem drag.

d) After laying, the workweek in which the bars must be placed and the time when we must not intervene in order

to allow complete curing, are specified in the instruction booklet in each tin of resin.