24

INSTRUCTIONS JIB CRANE SERIES GBA - GBP

MAN05MGO5

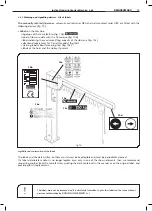

4.3.3 Assembly of the column – For GBA column-mounted cranes

Positioning of the foundation frame in the plinth:

•Thefixingofthecolumntothegroundcanbedoneinthefollowingways:

•usingafoundationframewithlogboltssunkintoaplinthmadeofreinforcedconcrete

•usingthebigplateandscrewanchorsordowelling.

•Thefixingofthecolumnusingboltsandscrewanchorsordowellingrequiresascrupulouscheckof

suitabilityinrelationtothetypeofsupportflooring.

•Thetechnicaldata,sothattheusercanchoosetherightsizeforthethefoundationplinth,areshown

in the table in paragraph 2.2.7

(“Fixing systems”p.12)

.The plinth size must be in relation to the real

consistencyofthegroundandthespecificmaximumpressurethatitcanbear.

•Thesuitabilitychecksofthefoundationaretheresponsibilityoftheuserandmustbecarriedoutby

technicalexpertswhojudgethefeasibilityandtakeresponsibilityforthis.

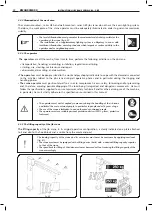

1. Screw tight the low nuts

2

on the log bolts

1,

leaving a threaded part up to have the corresponds protusion

ST,

(see “Fixing systems” on page 12) (fig. 21). Do the same operation on all 8 (eight) log bolts.

2. Insert all the logbolts

1

in the holes on the foundation frame

4,

so that the plate of the frame is resting on the nuts

and then tighten with the tall nuts

5,

interposing the washers

3.

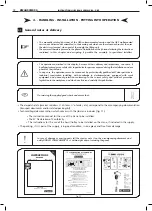

3. Sink the frame prepared in this way in the plinth casting, taking care that the upper plate remains on the same

level as the floor (fig. 22) Protect the threadings of the logbolts to avoid damage.

4. When needed, insert a tube into the plinth through which the electrical cable which powers the crane can be

passed (fig. 23).

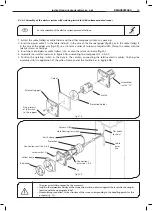

5. Level the foundation frame using if necessary a bubble and proceed to the filling and flint-glazing of the plinth (fig. 24).

6. Wait the necessary time before assembling the column so that the plinth can stiffen.

fig.22

fig.21

fig.24

fig.23

5

4

3

2

1

2

1

KMAN05MG05