28

INSTRUCTIONS JIB CRANE SERIES GBA - GBP

MAN05MGO5

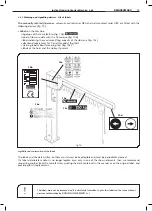

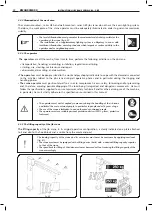

4.3.5 Assembly of the arm –For GBA column-mounted cranes and GBP wall-mounted cranes

Fortheassemblyofthearmproceedasfollows:

1. Sling the arm, using strips made of textile fibre arranged in a “loop”, corresponding to the handling points shown

on the labelling and lift it with suitable means (overhead travelling crane, travelling crane, etc.). Keep the girder

horizontal to the ground and constantly check the stability of the slinging which must not move from the handling

point. Avoid oscillations and swinging and, if necessary, to maintain the equilibrium use a rope tied to the ends of

the arm (fig. 42).

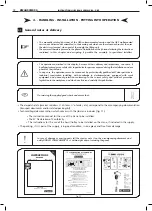

2. Line the arm up with the plates (of the bracket or column) and position the clutch plate

2

and the pressure plate

3

in the upper part of the tube, making sure at the same time that the clutch plate

2

and the pressure plate

3

fit

into the lower part (fig. 43).

3. Insert the tube between the plates

4

until the rotation axis of the tube coincides with that of the plates and insert the

rotation pivots

5

(upper side pivot with 6 holes, lower side pivot with 3 holes), after lubricating them with grease (fig. 44).

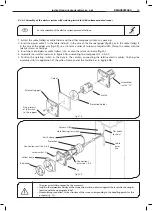

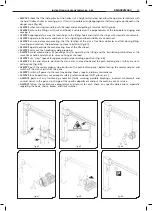

4. Block, with the clamping couples shown in the table, the pivots

5

with their related screws

6

in the three holes at

120 on the pivots’ flange

5

(fig. 45).

5. Insert in the remaining holes of the upper side pivots’ flange

5,

the springs

7

and the screws

6

checking carefully

that the shank of the screws fits into the housing on the pressure plates

(fig. 46).

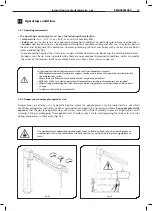

6. Regulate the slidability of the rotation of the arm, by acting on the braking system using register/adjuster screws

6,

until the traverse sensitivity required is obtained.

7. Carry out the check of the planarity of the arm

with the help of a level

,

Do this check by rotating the arm by

90°totheleftandtotheright(fig.47).

fig.42

fig.43

fig.44

• Keeping the arm clean is one of the indispensable conditions for its good sliding and to avoid a

premature deterioration of the rotation elements .

•Moderatelubricationwithgreaseofthebearingsisnecessary.

3

5

4

4

5

2

2

1

3

fig.45

fig.46

fig.47

5

6

5

6

7

8

9

9

9

L

L

L

9

L

KMAN05MG05