32

INSTRUCTIONS JIB CRANE SERIES GBA - GBP

MAN05MGO5

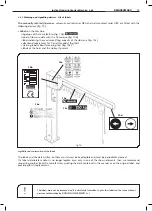

Beforeputtingthejibcraneintouse,carryoutthefollowingoperations:

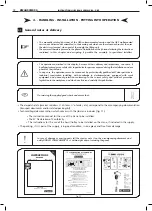

s#HECKTHEELECTRICALSYSTEMISINASUITABLECONDITION

•Checkthatthevoltageandlinefrequency,shownontherespectivemotorplates,correspondtothosedesigned

for the functioning.

•Checkthatthevoltagevaluetothemotorsiswithinthelimitsof+/-10%ofthenominalvalue.

•Checktherearegroundclampsandthattheyareconnectedcorrectly.

s#HECKTHECORRECTINSTALLATIONOFTHECRANE

•Checktherearenoobviousfaultsfollowingtheinstallationofthecrane.

•Checkthatalltheboltedjointsarecorrectlytightened.

•Checkthattheslidingtrackofthetrolleywheelsisintact,whichmustbefreefromobstacles,upwardprojecting

bumps, depressions, and foreign bodies.

•Checktheuniformsensitivityoftheflexingofthearm,inallitsamplitude.

•Checkthatthearmcanfreelyrotate,relatedtotheabsenceofobstaclesinthewholeareaofoperationofthe

crane and any interference.

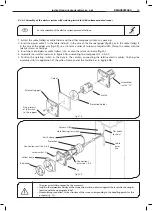

•Adjusttheascentlimitswitchesoftheelectrichoist(seeinformationintherelated“Instructionsforuse”),toallow

the maximum possible run. The ascent limit switch must be adjusted so that the hook at its lowest point is about

10 cm from the ground.

•Checkthatthereareendcatchesand/orstrikerplatesofthearmandtrolley.

•Checktherearestrikerplateswhichfunctionfortheinterventionofthetravellimitswitches,wheninstalledwith

electric trolley. These should be adjusted so they do not come into contact with the buffers.

•Checktherearenoleaksoflubricant.

• Check during the trial runs that there are no strange noises and/or vibrations and/or incorrect movements

(skidding of the wheels or, spontaneous movements of the trolley and/or the arm, etc).

s#HECKTHEFUNCTIONINGOFTHECORRECTROTATIONDIRECTIONOFTHEMOTORS

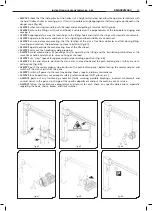

s)FTHECRANEISFITTEDWITHAHOISTANDELECTRICTROLLEY

•Operatethe“right/left”directionbuttonsandcheckthatthetrolleymovesfollowingthedirectionalarrowson

the crane girder;

s)FTHECRANEISFITTEDWITHELECTRICHOISTANDPUSHTROLLEY

•Operate,forbriefdistances,the“ascent/descent”buttons,takingcaretooperatefirstinonedirection(descent),

and then in the other (ascent) with two brief impulses necessary only to ascertain the correct direction of rotation,

without using any electric limit switches.

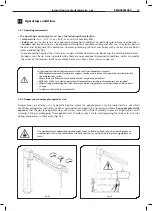

4.4.1 Preliminary operations - Adjustments and test runs

4.4

Putting the machine into operation

•Proceedfirsttothecheckofthetravelmovements,ifelectric,andthentotheliftingcheckand,inany

case, avoid intervening using the lifting limit switch.

•Iftherotationdirectionofthemotorsdoesnotcorrespondtothecontrolsofthepush-buttoncontrol

panel the limit switches do not halt the movement, and malfunctioning can occur.

•Ifthedirectionofthemovementdoesnotcorrespondtothefunctionshownonthepushbutton

control panel, halt the manoeuvre.

KMAN05MG05