40

INSTRUCTIONS JIB CRANE SERIES GBA - GBP

MAN05MGO5

5.2.6 Manoeuvres: lifting, trolley traverse and arm rotation

It is a good rule to perform one movement at a time, because only in this way a manoeuvre can be started, stopped

and constantly followed by the operator, who also has to avoid continuously switching the machine on and off even

for little movements.

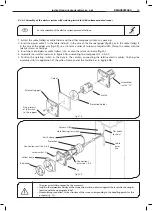

•Engagementoftheloadbythehookofthehoistandbytheliftingaccessoriesmustbecarriedoutwithgreatcare,

delicately and without jolting.

•Beginaliftingoperationbyslowlystretchingthechainuntiltheloadhasbeenliftedbyafewcentimetres,stopthe

manoeuvre and check the hold and stability of the load.

•Attheendofthemanoeuvre,placetheloadonthegroundcarefullyandremovethehookofthehoist.

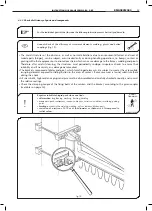

•

During lifting manoeuvres

the operator must avoid resting the hook on the ground or on loads to be lifted, to

avoid free oscillation of the chain. The operator must absolutely avoid making skew falls with the chain, which are

always dangerous and difficult to control (fig. 62)

•

During trolley travelling manoeuvres

it is obligatory to avoid violent collisions between the trolley /hoist and the

end buffer plates so as not to cause serious repercussions on the mechanical organs and on the steel structure.

•

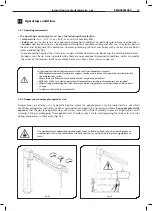

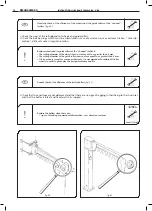

During manual travelling and/or rotation manoeuvres of the arm

the operator must handle the load by pushing

it and never by pulling it towards himself, to avoid the risk of crushing (fig. 63).

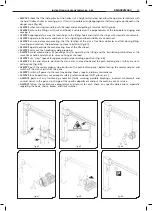

•Operatewithcareanddiligence,followthemanoeuvreconstantlyandvisuallycheckthebalanceofthe

mass being moved.

•Avoidsharporjoltingmovementswhichareverydamagingtothestabilityoftheloadbecauseofthe

dynamiceffectswhicharegenerated.

•Neverliftloadswithanunbalancedandnonbarycentricengagement.Neverneglecttohooktheload

and secure all original sling accessories. Do not secure the load with improvised slinging.

•Neverleavetheloadsuspended,oncethehandlingoperationhasbegunitmustbecompletedinthe

shortest time possible and the load must be positioned without crushing the lifting accessories.

5.2.7 Safety devices

•Cuttingoutthepowersupplyofthecranemustbedonebyswitchingoffthelineswitch/selector(notincludedin

the supply) and/or by pushing the “emergency stop” button on the push-button panel.

•Anelectricand/ormechanicallockpreventssimultaneoususeofcommandsforthetwodirectionsofthemotorsfor

both high and low speeds.

• A lack of voltage causes all movements of the hoist and trolley to be stopped immediately, as the motors are

equipped with an automatic braking device.

•Asafetylatchisinstalledontheliftinghooktopreventaccidentalunhookingoftheslingingand/orloading

•Thelifting,translationandrotationlimitswitchesboundthemaximumverticalandhorizontaltravelingoftheload.

They are emergency devices and are not suitable for turning off the machine or to begin new operations.

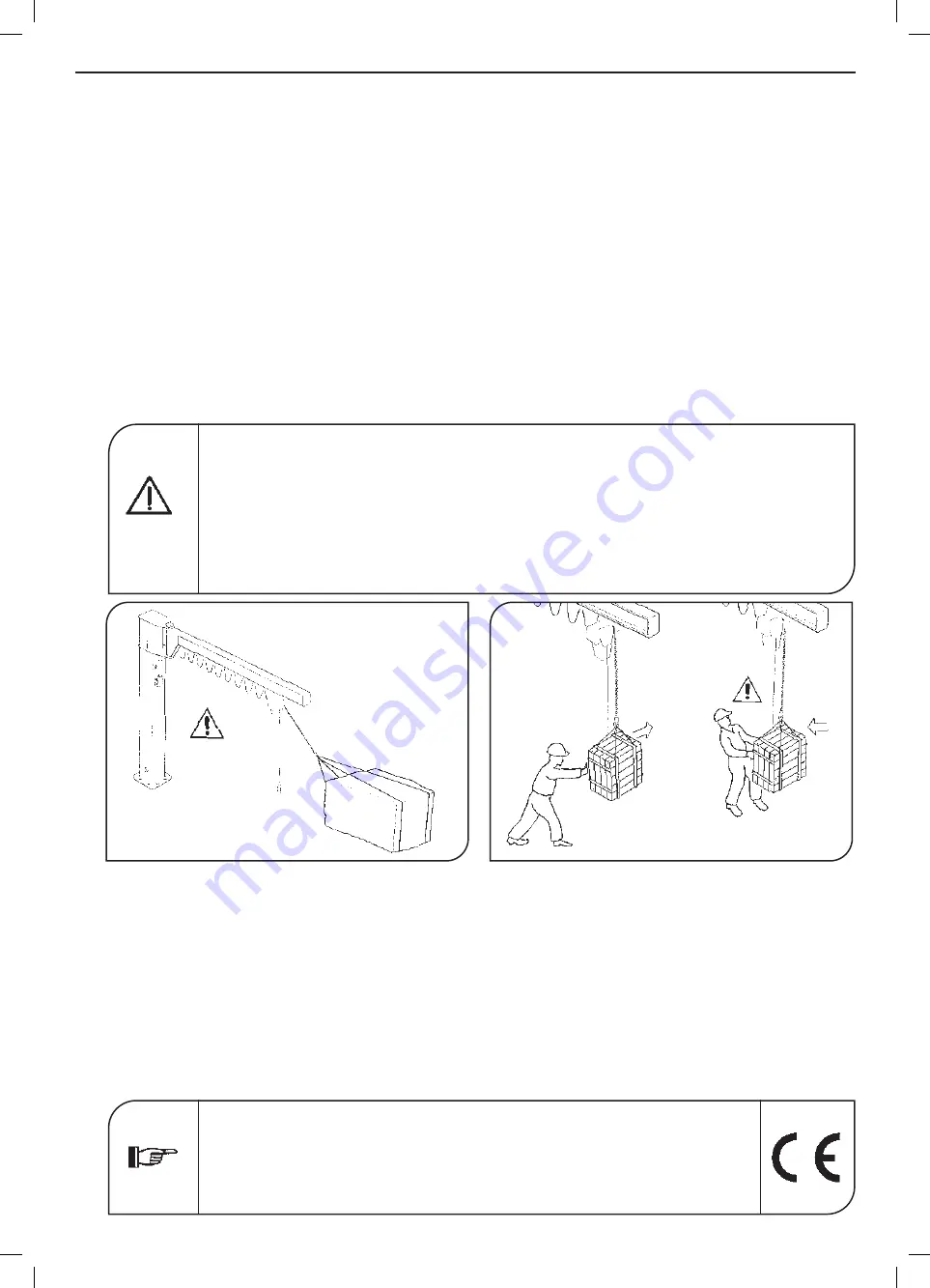

•WhenthesafetydevicesarenotsuppliedbyDONATISOLLEVAMENTIS.r.l.,theymustbe

installedbythepurchaser.

•Useofthejibcraneand/orapplicationoftheCEmarque,shownhereontheright,is

forbidden before the crane has been completed according to the specifications detailed

in this point.

fig.63

fig.62

KMAN05MG05