MAN05MGO5

INSTRUCTIONS JIB CRANE SERIES GBA - GBP

47

To be capable to adequately carry out maintenance work of jib cranes maintenance staff must:

• Know the laws in force related to accident prevention during work carried out on machines with motor

transmissions and be able to apply them.

•Havereadandunderstoodchapter3“SafetyandAccidentPrevention”.

•Beabletouseandconsultthisdocument.

•Knowthefunctioningofthemachine.

•Recogniseirregularitiesregardingfunctioningandwhennecessarytakenecessarymeasurestorectifythem.

Professionalfiguresappointedandauthorisedtocarryoutmaintenanceonthecraneare:

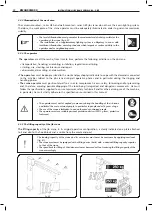

s4YPICALMAINTENANCEACTIVITIES

•Verificationofproperfunctioningofthejibcrane.Cooperationwithstaffappointedtoperiodical

and/or extra maintenance work, after having informed them of any anomalies found in the functioning.

•Cleaningandlubricationofthepartsofthecrane(hoist)whichtheoperatorisnormallyincontactwith

(push-button panel, hook) and simple maintenance work which does not require intervention at a height

(e.g. lubrication of the thrust bearing of the hook).

s4ECHNICALKNOWLEDGEREQUIRED

•knowledgeofthefunctionsanduseofthejibcrane.

•

knowledge of the lubricants utilised in the crane and in the hoist and of the dangers associated with their use.

s1UALIFICATIONREQUIRED

•suitabilitytotheworkinrelationtothespecificoperativeandenvironmentalcharacteristics.

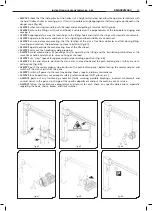

s4YPICALMAINTENANCEACTIVITIES

•mechanicalregulationoftheclearanceofbrakesandmechanisms

•testmovementsandmechanicalregulationofthesafetydevices

•checkmechanicalclearanceandwearofthecomponents(chain,hook,etc.)

•replacementofcomponentswhichcanwearout(chain,hook,chainguide,pulleys)accordingtothis

publication

•ordinarymaintenanceofmechanicalunitsaftersubstitutionofpartswithoriginalspareparts

s4ECHNICALKNOWLEDGEREQUIRED

•goodknowledgeofmechanicalliftingsystemsandhandlingwithamanualandmotordrivensystem

•goodknowledgeofsafetydevicesusedonthehoist(limitswitches,brakes,overloadswitch,etc.)

•

basic knowledge of the moderately difficult techniques for electric checking and adjustment (limit switch

adjustment, replacement of fuses, motor connection, etc.)

•

knowledge of the methods of measurement and testing to determine the actual state of the conditions of

the crane and of the hoist (tests of: brakes, chain and hook wear, wheel wear, anomalous noise, etc.)

•logicaltrouble-shootingmethodsofnoncomplexbreakdownsandevaluationoftheresults

•abilitytoarrangethenecessarymeasurestoputthehoistbackintoworkingorder

•abilitytowriteamaintenanceinterventionreport

s1UALIFICATIONREQUIRED

•Completetrainingofanindustrialmechanichavingaspecialisationinandexperienceoflifting-system

maintenance or of industrial handling.

6.2

The qualifications of maintenance staff

Operatorofthejibcrane.

Mechanical maintenance officer

KMAN05MG05