MAN05MGO5

INSTRUCTIONS JIB CRANE SERIES GBA - GBP

51

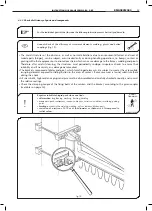

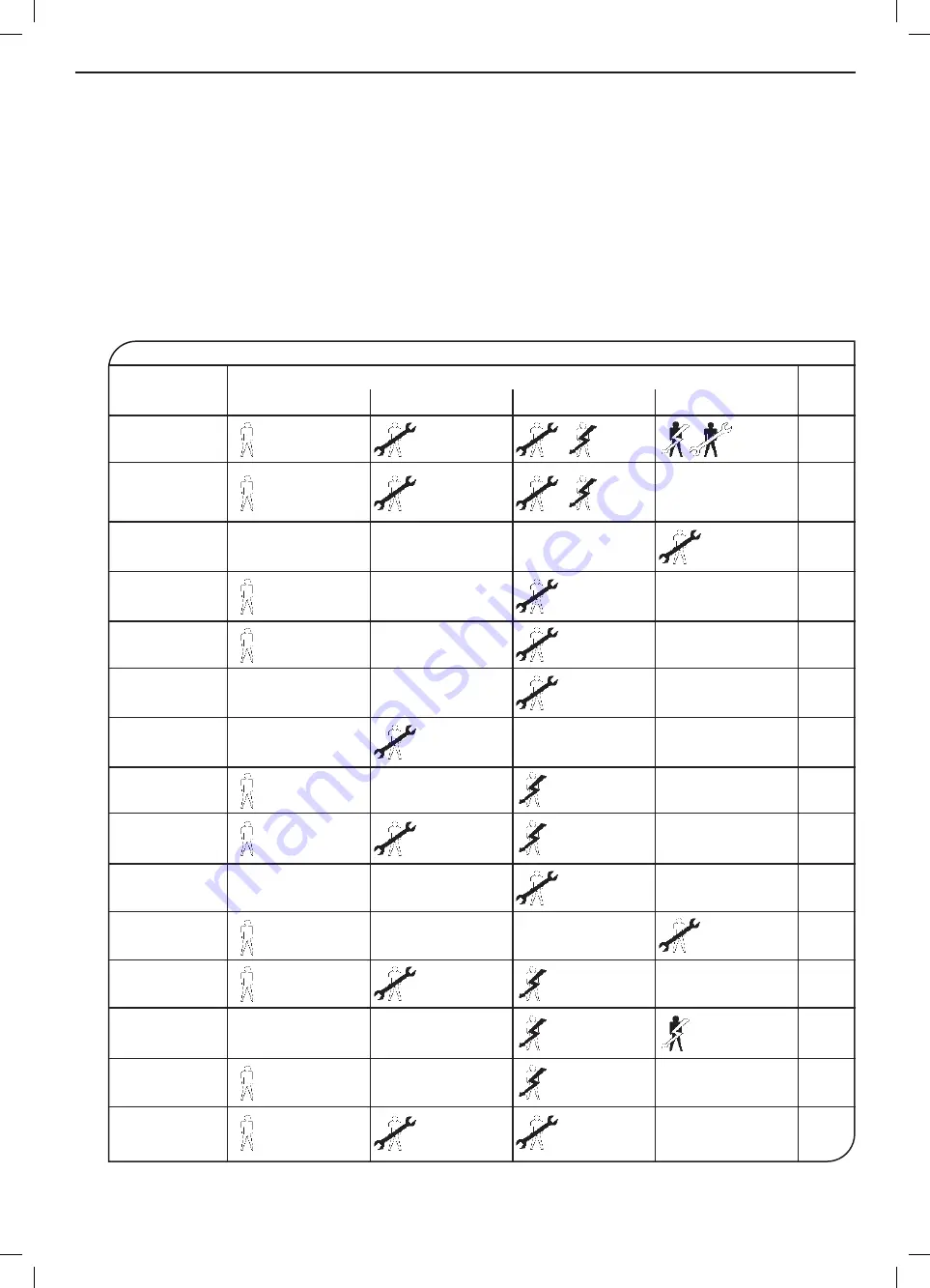

6.3.2 Frequency and deadlines for maintenance work

The periodicity of the following operations is for jib cranes used in normal working conditions and is valid up to the

M5 group (ISO norm 4301/86) or 2 m (FEM rule 9.511).

If the jib crane is used normally and correctly for a daily 8 hour shift, overhaul can take place after a period of about

10 years (FEM rule 9.755 – S.W.P.). If used during a number of shifts then the maintenance periods must be reduced

proportionately.

Object of the check

Checks

Inspections - Testing

Signs pictograms

warning signs and plates

Structural elements

Welding Pivots

Bolted couplings

Chain

Securing elements

,IFTINGHOOK

,OADWHORL#HAINGUIDE

Transmission of the

hook block

,IFTINGREDUCER

Translation reducer

,IFTINGMOTOR

Translation motor

,IFTINGBRAKE

Translation brake

Rotation brake

Wheels and sprockets

Rotation bearings

Trolley buffers

anti-collision lug

Electrical system

Push-button panel

and cable

Overload switch

Clutch device

,IFTINGLIMITSWITCH

Translation limit switch

Cleaning and

lubrication

Daily

Monthly

Quarterly

Annually

General visual checks.

Verify good functioning

General

visual inspections

Wear

check

Annual test

32

18

52

Hoist

manual

Hoist

manual

Hoist

manual

Hoist

manual

Hoist

manual

Hoist

manual and

page 54

Hoist

manual and

page 53

Hoist

manual and

page 53

Hoist

manual and

page 54

Hoist

manual

Hoist

manual

Hoist

manual and

page 55

Wear and efficiency

check

Check bolted and

soldered joints

Wear and

efficiency check

Wear and

efficiency check

Check wear

and efficiency

Wear and

efficiency check

Calibration

check

Wear and

efficiency check

Loaded testing

Loaded testing

Loaded testing

Wear and

efficiency check

Leakage check

Lubricate chain, hook

and mechanisms

Loaded testing

Wear check

Wear check

Noise check

Loaded testing of

braking distances

Visual inspection for

external breakage

push-button panel/

cable

Inspection of

general lubrication

Visual inspection

Visual inspection and

check safety latch

Check correct

functioning

Check correct

functioning

Check correct

functioning

Check correct

functioning

Check correct state of

cleanliness and

lubrication

Page

Periodic checks

Table of periodic checks and maintenance

Legibility of signs and

pictograms, warning

signs and plates

Visual inspections

of wholeness and

clening of plates

and signs

Check

suitability

Visual check

KMAN05MG05