52

INSTRUCTIONS JIB CRANE SERIES GBA - GBP

MAN05MGO5

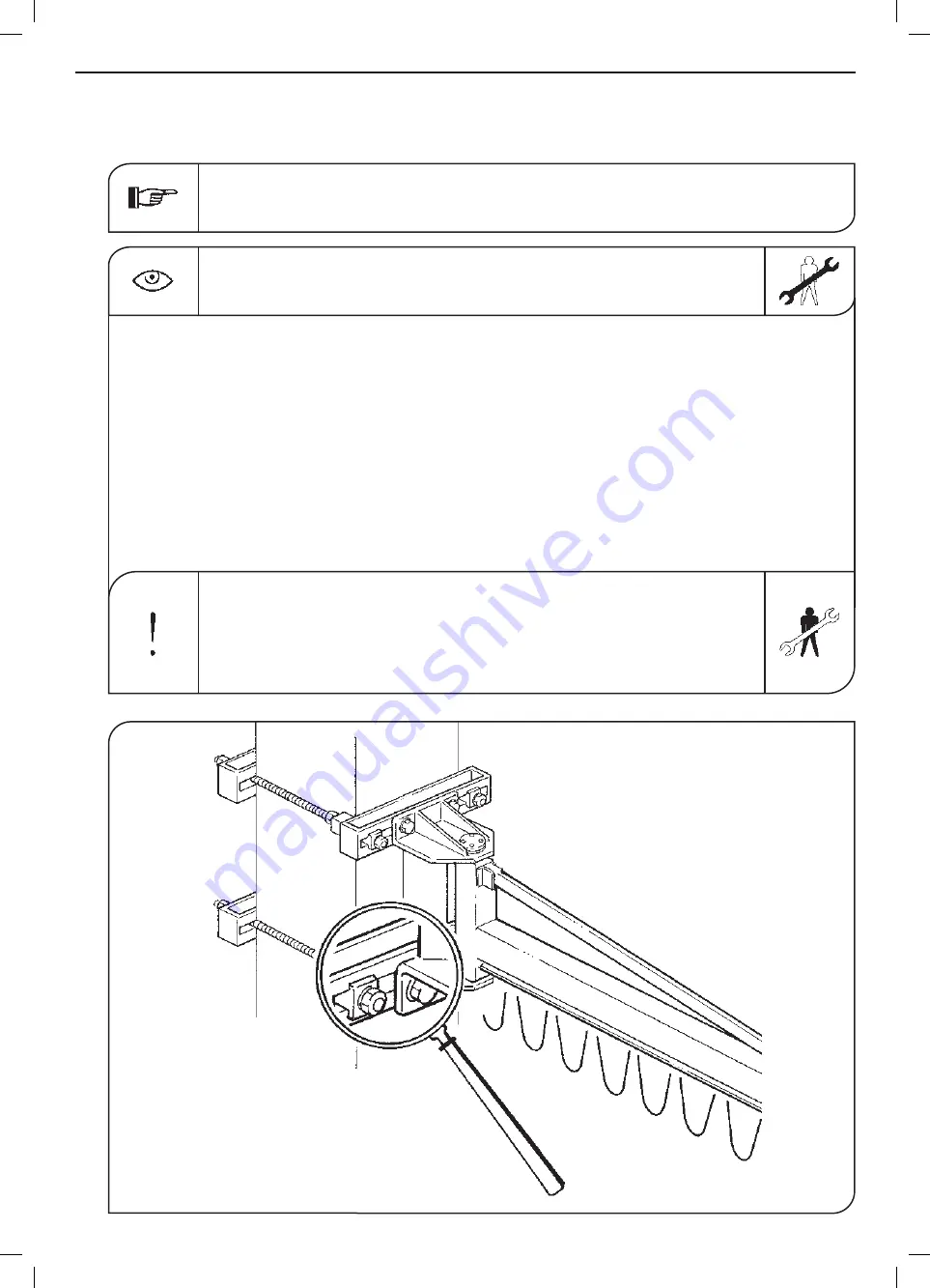

6.3.3 Check of efficiency of parts and components

•Themetalstructuresofthejibcrane,aswellasnormalalterationsduetoenvironmentalfactorsandwearof

mobile parts (hinges), can be subject, even inadvertently or during handling operations, to bumps, contact or

grazing with other equipment or to anomalous strain which can cause damage to the frames, welding and pivots.

Therefore, after careful cleaning, the structures must periodically undergo scrupulous checks to ensure their

suitability and if necessary, any damage be remedied.

•Thebrackets,composedofplatesandpivot,whichformhingedelements,aresubjecttowearastheyaremobile,

swinging elements exposed to sliding friction in the areas of contact. If excessive wear is found, substitute them

during the check.

•Allscrewbolts,highresistanceplugsandpinsmustbedisassembledandcarefullycheckedannually,andsomust

the relative seatings.

•Checktheclampingcoupleofthefixingboltsofthecolumnandthebracket,accordingtothegivencouples

(see tables on page 12).

Fortheindividualpartsofthejibcranethefollowinginstructionsmustbestrictlyadheredto:

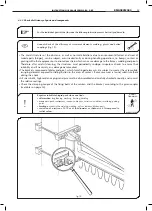

Annual check of the efficiency of structural elements, welding, pivots and bolted

couplings

(fig. 79):

Repairorsubstitutehingedpartswhereonefinds:

•deformation:

lengthening, crushing, staining, bending

•wear:

WORNPARTSSCARCEMENTINCISIONSABRASIONSCORROSIONOXIDATIONSCRATCHINGPEELING

point

•breakage:

CRACKSINTHEWELDINGCRACKINGCUTSORINCISIONSBROKENPARTS

•variationofasection

*

10%,orofthediameterorthickness

*

5%comparedto

initial values.

DONATI

TECHNICIAN

DONATISERVICE

fig.79

KMAN05MG05