CPRS-1400,1400D INSTALLATION MANUAL

Issue : 2004.07

ED : 0

CPRS-1400,1400D INSTALLATION MANUAL 11 /47

●

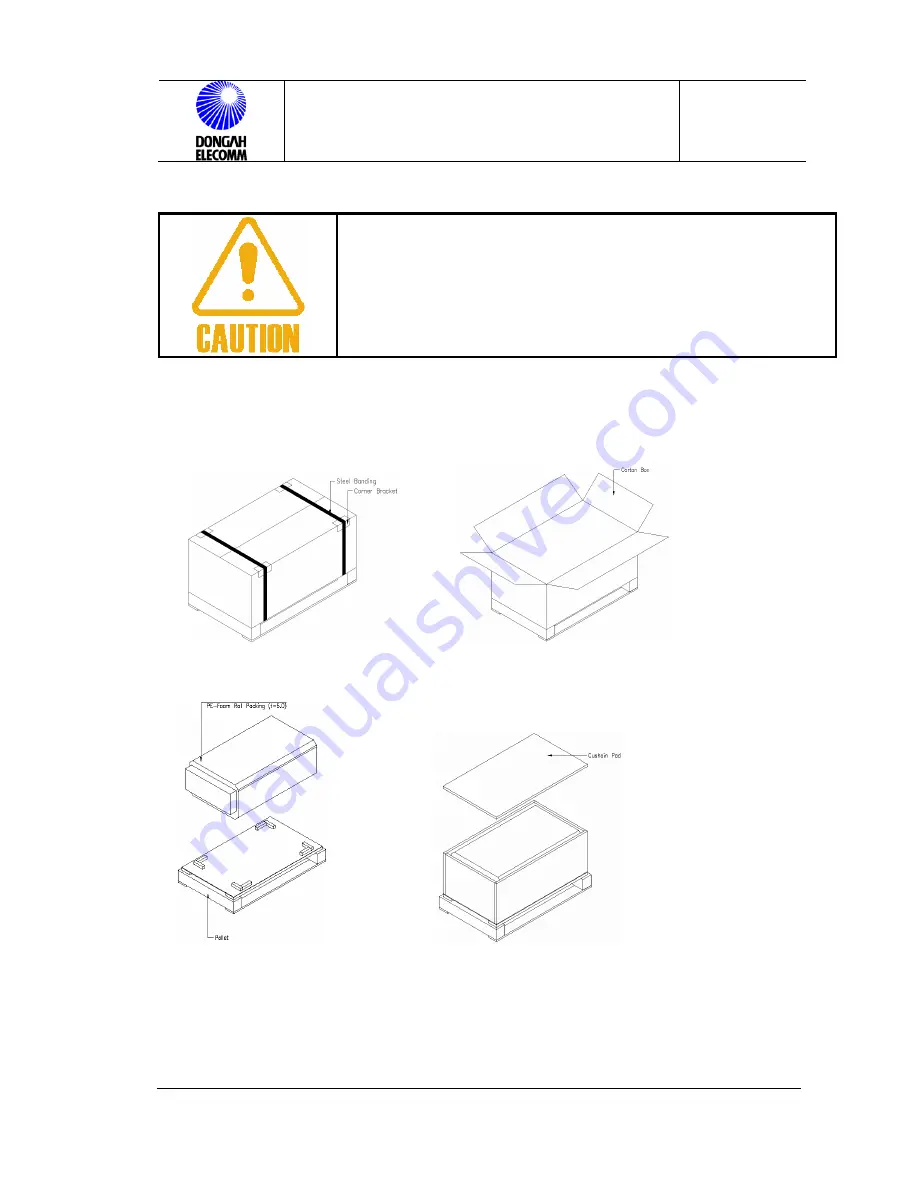

Before unpacking the system, read carefully the listed directions.

●

Pay special attention not to be injured when handling sharp articles

(steel bank, conner bracket etc.)

●

Unpack the system in due order so that the system will not be

broken out.

1) Get rid of the steel bands. 3) Take apart the carton box

2) Get rid of the conner brackets

5) Separate the pallet from the enclosure.

4) Take out the cushion pad 6) Get rid of the inner package

Figure 1. Unpacking