26

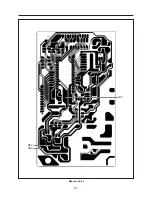

PRINTED CIRCUIT BOARD

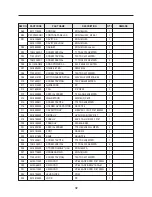

1. CIRCUIT CHECK PROCEDURE

1. Low Voltage Transformer check

• The low voltage transformer is located on the P.C.B.

• Measuring condition: input voltage : 120V / Frequency : 60Hz

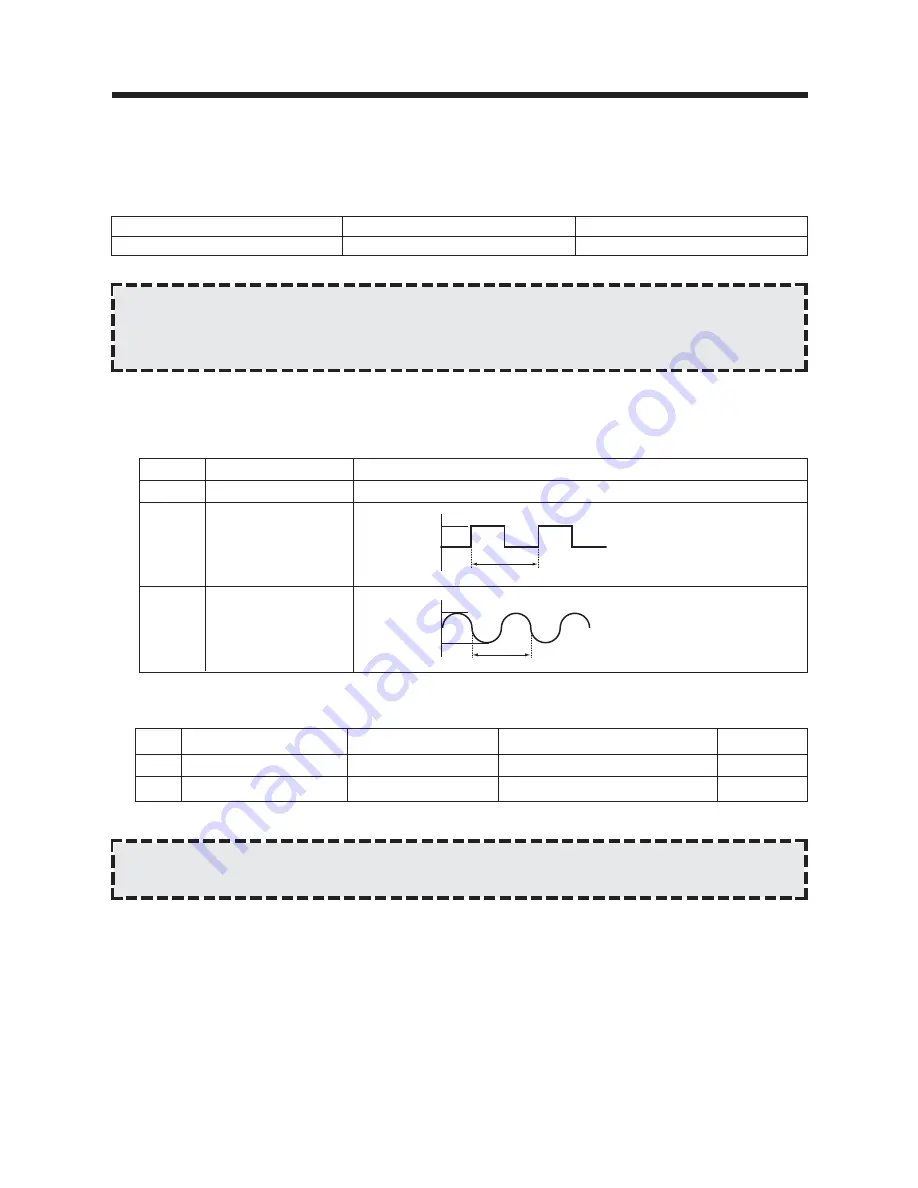

2. Voltage check

• Key check point

• Check method

NO

CHECK POINT

REMARK

1

IC 1 PIN 5

5 VDC

2

IC 1 PIN 8

3

IC 1 PIN 35 OR PIN 36

NOTE :

Each measure point must be measured with GND points.

NOTE :

1. Refer to Circuit Diagram.

2. Secondary side voltage of the low voltage transformer changes in proportion to fluctuation of power source voltage.

3. The allowable tolerance of the secondary voltage is within ± 5% of nominal voltage.

Terminal Voltage

(4,5)-6-7

LOAD

AC 12.6 V

NO LOAD

AC 14.7 V

NO

MEASURE POINT

WAVE FORM

REMEDY

REMARK

1

MP1

DC 5V ±0.25V

Replace VL1, EC1

NO LOAD

2

MP2

DC 15V ±2.0V

Replace EC2, D11, D13, D14

NO LOAD

T

T:16.67ms(60Hz)

5V

0V

T

T:250ns(4MHz)

5V

0V

Summary of Contents for KOR-164H0W

Page 5: ...5 EXTERNAL VIEW 1 OUTER DIMENSION ...

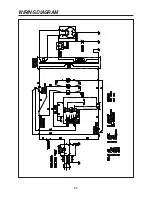

Page 25: ...25 WIRING DIAGRAM ...

Page 27: ...27 Measure Point MP1 GND MP2 ...

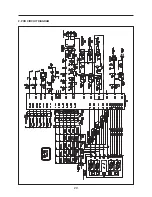

Page 29: ...29 2 PCB CIRCUIT DIAGRAM ...