raise the blade and counterclockwise

to lower it. (

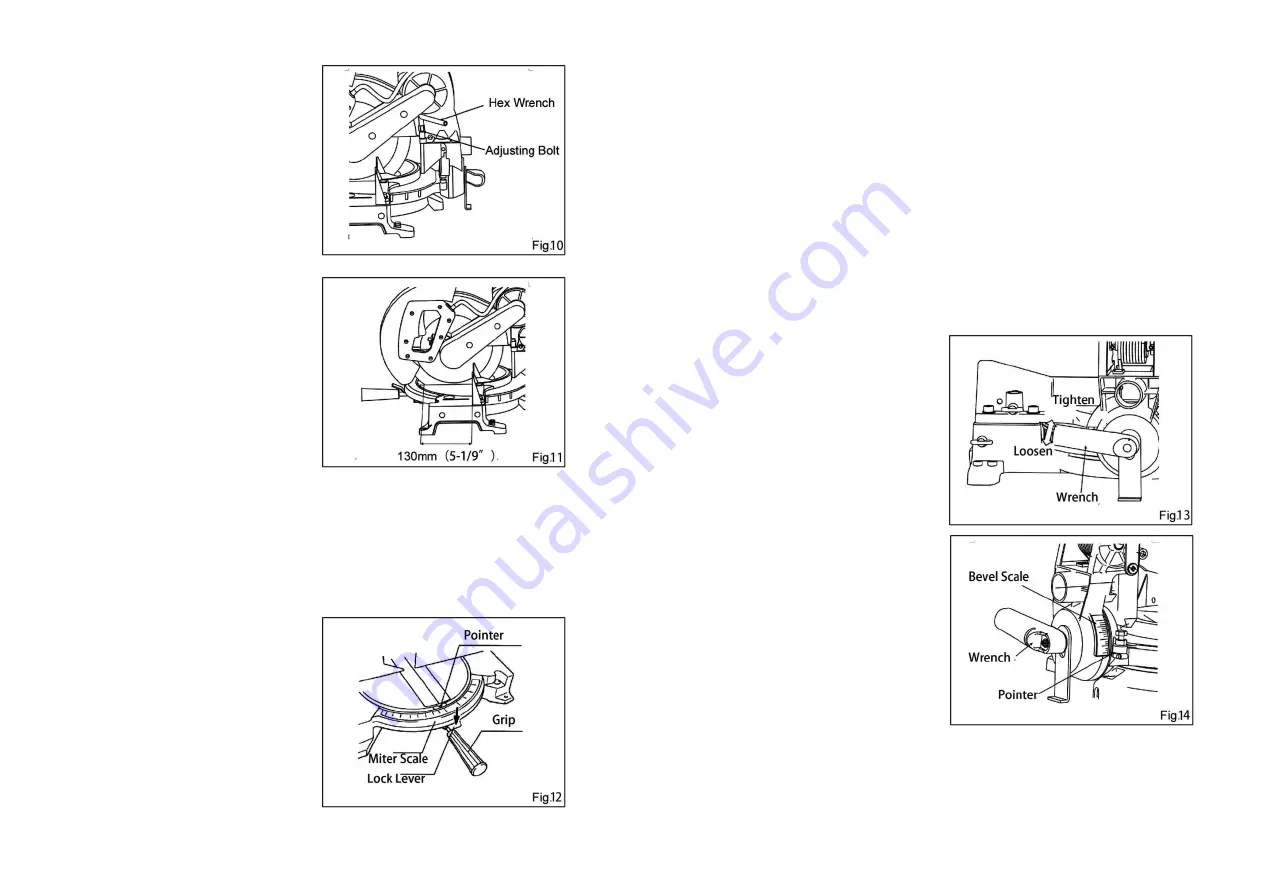

Fig. 10

)

Refer to the following procedures for

the adjustment:

Unplug the tool and lower the handle

completely, use the socket wrench to

turn the adjusting bolt until the

distance between the front face of the

guide fence and the front point where

the blade crossing with the top

surface of the turn base meets 130

mm (5-1/9

”). (

Fig. 11

)

With the tool unplugged, rotate the

blade by hand while holding the

handle all the way down to be sure

that the blade does not contact any

part of the lower base. Re-adjust

slightly, if necessary.

Adjusting the Miter Angle

CAUTION:

Be sure to raise the handle fully

while turning the turn base.

Loosen the grip by turning it

counterclockwise. Turn the turn base

while pressing down the lock lever.

When the grip has been moved to the

position where the pointer points to the desired angle on the miter scale, securely

tighten the grip clockwise. (

Fig. 12

)

Adjusting the Bevel Angle

CAUTION:

Be sure to raise the handle fully while tilting the saw blade.

The saw blade can be tilted at 45° to the left only when the sub-fence locates at the

left position (

refer to the instructions of

“

Sub-fence

”

).

After changing the bevel angle, always secure the arm by tightening the lever

clockwise.

To adjust the bevel angle, loosen the lever

at the rear of the tool counterclockwise. (

Fig.

13

)

Push the handle to the left to tilt the saw

blade until the pointer points to the desired

angle on the bevel scale. Then tighten the

lever clockwise firmly to secure the arm.

(

Fig. 14

)

-11- -12-