6. Under normal operation, the tool is designed to produce vibration. The screws

can come loose easily, causing a breakdown or accident. Check tightness of

screws carefully before operation.

7. Under normal operation, the tool is designed to produce vibration. The screws

can come loose easily, causing a breakdown or accident. Check tightness of

screws carefully before operation.

8. Always be sure to have a firm footing. Wear safety belt when using this tool in

high locations and ensue no one is below.

9. Keep hands away from the rotating parts.

10. Do not leave the tool running. Operate the tool only when hand-held.

11. Do not point the tool at any one in the area when operating. The bit could fly

out and injure someone seriously.

12. Do not touch the bit or parts close to the bit immediately after operation; they

may be extremely hot and could burn your skin

SAVE THESE INSTRUCTIONS.

WARNING!

MISUSE or failure to follow the safety rules stated in this

instruction manual may cause serious personal injury.

INSTRUCTIONS FOR OPERATION

Setting Operating Mode

Caution:

Always be sure that the tool is switched OFF before changing the operating

mode, or the gears inside the tool maybe damaged.

If the drill bit gets stuck by the steel hidden in the wall during impact drilling, and

the tool rotates due to the kickback, hold the handle and auxiliary handle firmly

to avoid personal injuries.

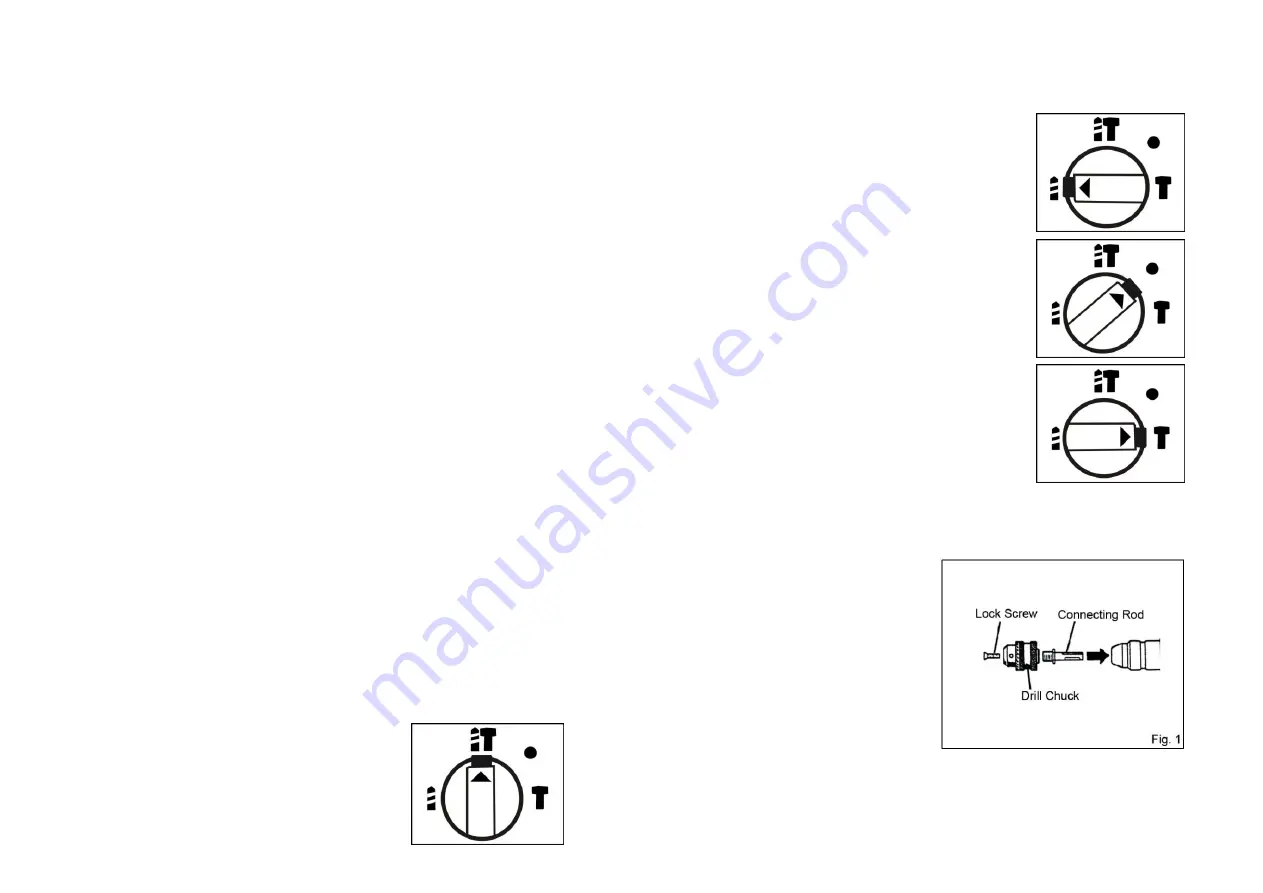

The Operating mode can be changed by turning the

operating mode selector.

Drilling Operation

When impact drilling on the concrete or stone, turn the selector to the position as

shown in the figure.

When normally drilling on the wood, metal, ceramics or

plastic, turn the selector to the position as shown in the

figure.

Demolition Operation

When the position of chisel needs adjusting during

operation, turn the selector to the position as shown in the

figure to avoid gears from meshing and then adjust the

chisel.

(

Z1C-FF05-26/Z1C-FF05-26B

)

After adjusting the chisel, turn the selector to the position

as shown in the figure to restart demolition operation.

Installing

SDS-plus Hammer Drill Bit

SDS-plus hammer drill bit can be used

when drilling on the steel, wood or plastic.

Screw the drill chuck in the connecting rod

and tighten the lock screw. Then insert the

connecting rod into the collect in the same

way as installing SDS-plus hammer drill bit.

SDS-plus hammer drill bit and drill chuck

are optional accessories.

(Fig. 1)

Installing /Removing Drill Bit

-5- -6-