CAUTION:

Always be sure that the tool is switched OFF and unplugged before installing or

removing the drill bit.

The SDS-plus drill bit will be

off-center when rotating with no-load,

but it will align with the center

automatically during operation and

its precision won

’t be affected.

Clean the bit shank and smear it with

bit grease before installation.

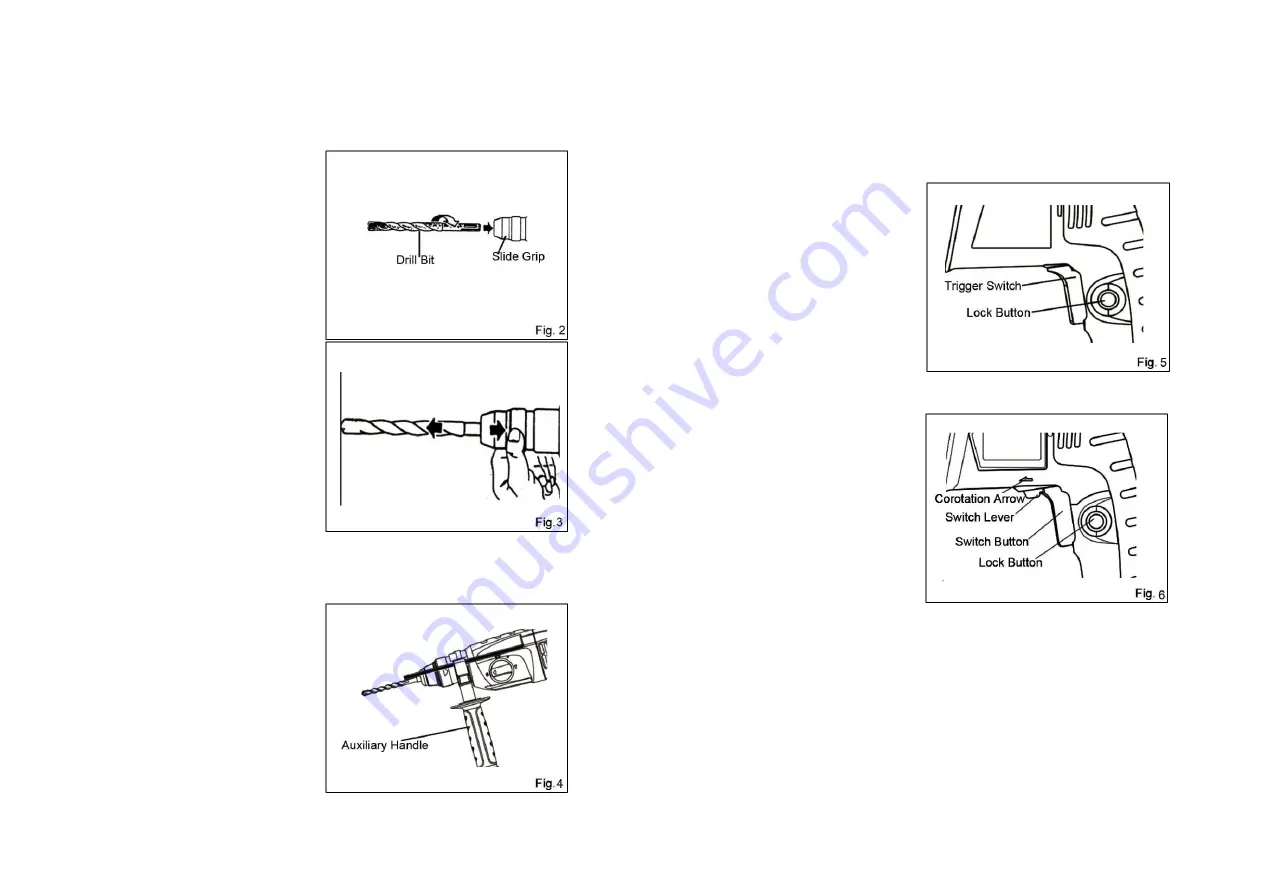

To install the drill bit (SDS-plus shank),

fully pull back the slide grip and insert

the drill bit as far as it will go while

rotating. (

Fig. 2

)

By releasing the slide grip, the drill bit

will be secured automatically.

To remove the SDS-plus drill bit, fully

pull back and hold the slide grip and

the drill bit can be removed. (

Fig. 3

)

Auxiliary Handle

Always use the auxiliary handle

ensure operating safety. Loosen the

auxiliary

handle

by

turning

it

counterclockwise, swing it to the

desired position and then tighten it by

turning clockwise. (

Fig. 4

)

Switch Action

CAUTION:

Before plugging in the tool, always check to see that the trigger switch actuates

properly and returns to the

“OFF” position when released.

To start the tool, simply pull the switch

trigger. Release the switch trigger to

stop.

For continuous operation, pull the switch

trigger and then push in the lock lever.

To stop the tool from the locked position,

pull the switch trigger fully, and then

release it. The rotating speed of the tool

becomes faster and faster until it

reaches the full speed during the

process of pressing the switch. (

Fig. 5

)

The switch of Z1C-FF05-26 is with

positive and negative going motion,

which can be used to change the tool

’s

direction of rotation. You can only

change it when the tool completely stops

rotating, otherwise the tool will be

damaged. (

Fig. 6

)

Set the direction of

rotation for hammer drilling, drilling and chiseling always to right rotation.

Depth Gauge

CAUTION:

The depth gauge cannot be used at the position where he depth gauge strikes

against the tool body.

-7- -8-