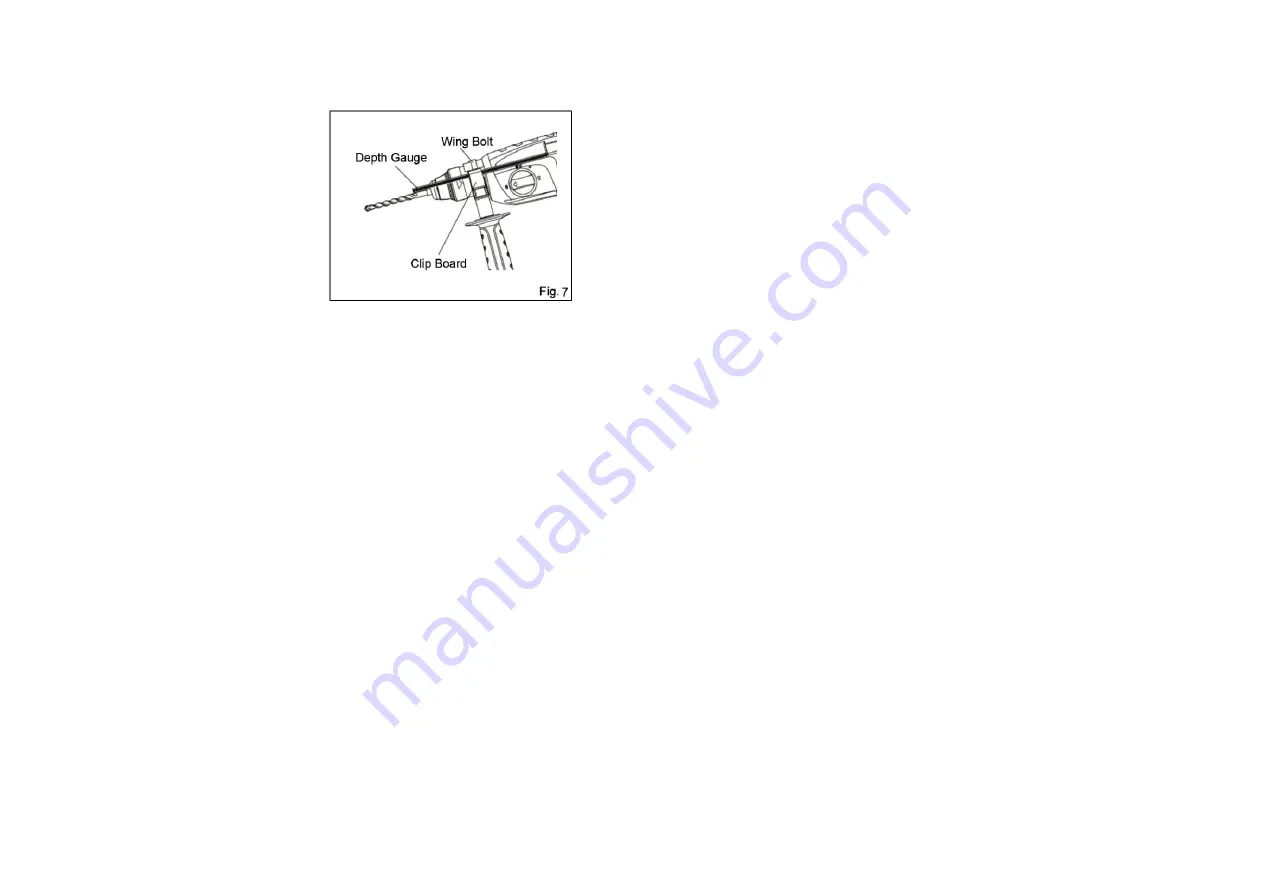

The depth gauge enables the drilling depth to be set for convenient drilling holes

of uniform depth.

Loosen the auxiliary handle, and insert

the linear part of the depth gauge into

the fitting hole of the clip board. (

Fig. 7

)

Move the depth gauge to the desired

depth and secure it by rotating the

auxiliary handle clockwise.

MAINTENANCE AND INSPECTION

CAUTION:

Always be sure that the tool is switched off and unplugged before attempting to

perform inspection or maintenance.

1.

Inspecting Drill Bits

Blunt drill bit or chisel will decrease the work efficiency and causes the motor

be overloaded. Exchange or sharpen your drill bits when they become blunt.

2.

Inspecting the Mounting Screws

Regularly inspect all mounting screws and ensure that they are properly

tightened.

Should any of the screws be loose, retighten them immediately. Failure to do

so could result in serious hazard.

3.

Maintenance of the Motor

The motor unit winding is the very

“heart” of the power tool. Exercise due care

to ensure the winding does not become damaged and /or wet with oil or water.

4.

Inspecting and Replacing Carbon Brushes

Remove and check the carbon brushes regularly. Replace when they wear down

to the limit mark. Keep the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same time. Use only identical

carbon brushes.

Use a screwdriver to remove the brush holder caps. Take out the worn carbon

brushes insert the new ones and secure the brush holder caps

5.

Replacing Dust Cap

Replace the dust cap once it is damaged to avoid chippings from getting into the

collet. Clean the collet regularly.

.

※

Damaged cord must be replaced by a special cord purchased from authorized

service center.

※

To maintain product SAFETY and RELIABILITY, repairs, any other

maintenance or adjustment should be performed by authorized centers, always

using original replacement parts.

-9- -10-