Electric and Instrument

EL-21

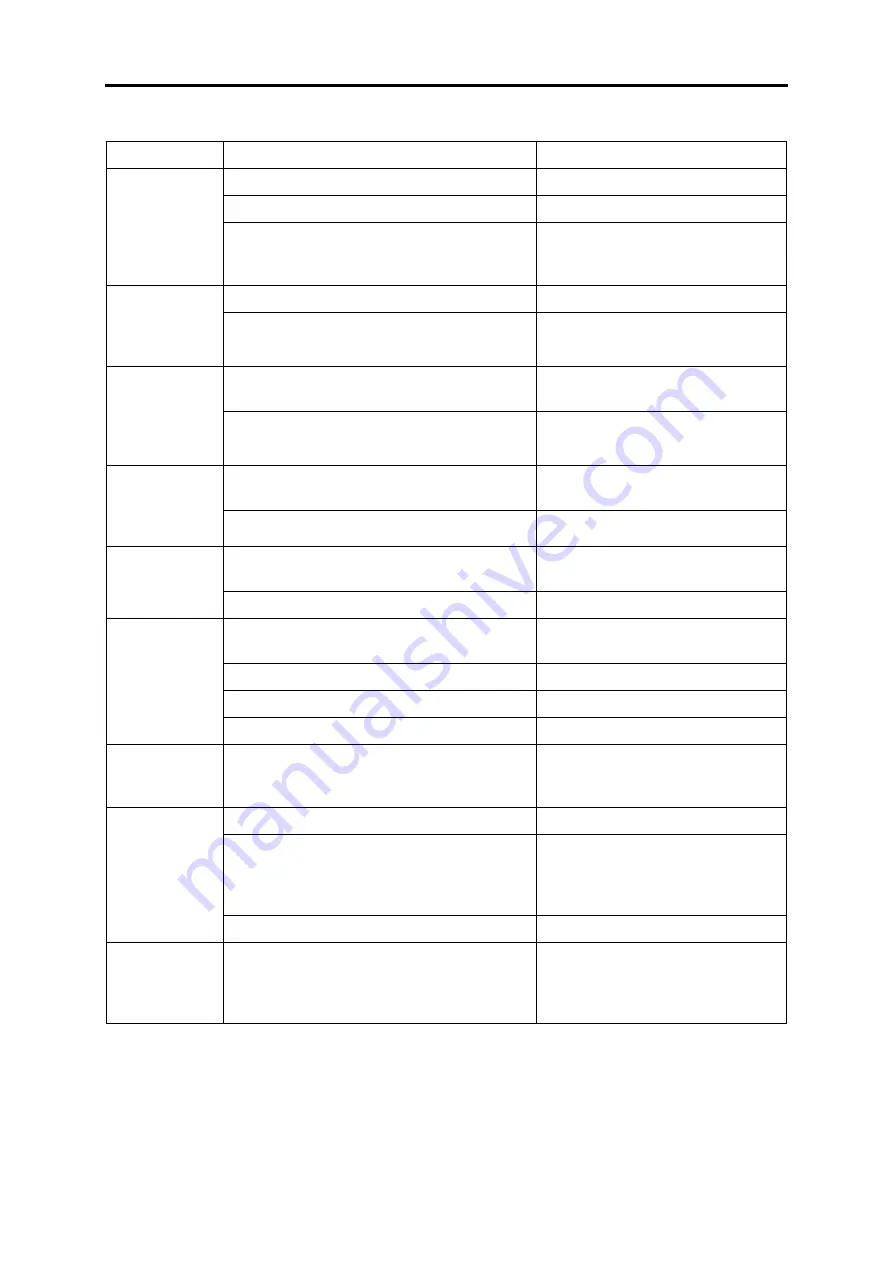

Trouble analysis

Trouble

Cause

Method

Both the speed

division and the

distance count-

ing division of

the speedometer

do not work

Flexible shaft core broken

Replace

Odometer rotating shaft seized

Replace the odometer

Square connector nut slackened

Tighten again

Only the speed

division of the

speedometer does

not work

Needle deformed and seized with dial or glass

Correct

Drive worm wheel and worm, and inductive plate

seized, broken, or dirtied

Replace or clean

The needle and

the accumulated

machine do not

run simulta-

neously

Drive gear or driven gear of the speedometer dam-

aged

Replace meter

Meter failed

Replace meter

The deflection

indication of the

needle is too

high.

Speedometer flexible shaft deformed or radius

area bent

Correct the flexible shaft

Input shaft or gear worn

Replace meter

The speedometer

indication is on

the low side

Transmission output shaft slipped

Tighten the flange fork under the rec-

ommended torque

The magnetic effect of the magnetic steel reduced

Replace

Needle indica-

tion error

Hairspring deformed or deviate from the original

position

Move the hairspring to one side to

adjust the indication of the needle

Magnetic body cracked

Replace meter

Dimension of tyre is wrong

Replace and use the recommended tyre

Speed gear worn or damaged

Replace meter

The needle

deflection

exceeds the dial

Grease on the magnet

Clean out the grease

The speed needle

of the speedome-

ter works

unsteadily

Hairspring broken

Replace meter

At the constance velocity of the vehicle when the

speed needle's indication unsteadily reaches to

3km/h, it is in trouble. Check the curvature of the

flexible shaft to see if it is too small.

Adjust

Flexible shaft core seized

Clean and lubricate

Speedometer nee-

dle oscillates

severely

The axial clearance of the flexible shaft is too big

causes the flexible shaft and speedometer's rotat-

ing shaft sometimes engaged, sometimes sepa-

rated.

Replace shaft core

Summary of Contents for DFA1101GZ5AD6J-907

Page 1: ...DFA1101GZ5AD6J 907 SERVICE MANUAL DONGFENG AUTOMOBILE CO LTD 2006 05 ...

Page 24: ...Clutch CL 8 ...

Page 34: ...Transmission MT 9 16 Lift the countershaft out by using crane or hoist Transmission mainshaft ...

Page 63: ...Transmission MT 38 ...

Page 123: ...Brake System BR 12 ...

Page 131: ...Cab BF 7 Cab External Trims ...

Page 133: ...Cab BF 9 Front and rear window Cab door seal strip ...

Page 134: ...Cab BF 10 Door outside molding Foot step shield and mat ...

Page 149: ...Air conditioner and Heater BF 25 Schematic Circuit of Air condition System ...

Page 150: ...Air conditioner and Heater BF 26 ...

Page 165: ...Electric and Instrument EL 14 Electric wiring diagram ...