P/N 1808922 Rev. C

10

Electric Installation

- continued

TEST OPERATION

STEP 6:

Divide portion of dual-conductor wire into 2 single-strand

wires (see caution). Cut section of single-strand wire to

run from positive terminal on battery to circuit breaker.

Crimp 3/8" ring terminal

6

onto one end of wire and 1/4"

ring terminal

5

onto other. Connect 3/8" ring terminal

to positive battery post and connect 1/4" ring terminal

to post on circuit breaker marked BAT.

STEP 9:

Run 3-strand jacketed toggle switch wire to solenoid

and cut to length. Connect wire ends to solenoid,

placing ring terminal

5

on post marked BATT+ and

2 quick disconnects to tabs marked T1 and T2.

STEP 10:

Slide solenoid cover under bolt heads and washers

holding solenoid in place. Tighten fasteners to hold

cover and solenoid in place.

STEP 11:

Operate toggle switch to verify tarp is moving in same

direction as shown on toggle. If tarp is not moving

in same direction as toggle, either swap 2 wires

connected to tabs T1 and T2 on solenoid or 2 wires

connected to motor.

STEP 7:

Locate toggle switch where switch can easily be ac

-

cessed by system operator. Weld toggle switch plate

in place.

STEP 8:

Fasten toggle

switch to

plate with

screws

A

and

washers

T

.

STEP 5:

Cut section of dual-conductor wire to run from solenoid

to battery. Crimp two 3/8" ring terminals

6

on one end of

wire and connect terminals to posts on solenoid marked

Batt+ and Batt-. Crimp one 1/4" ring terminal

5

and

one 3/8" ring terminal

6

on other end of wire. Connect

1/4" ring terminal to circuit breaker post marked AUX

and connect 3/8" ring terminal to negative battery post.

STEP 3:

Cut section of dual-conductor wire to run from solenoid

to electric motor.

toggle

switch

plate

toggle

switch

plate

toggle

switch

solenoid

tighten

fasteners

solenoid

cover

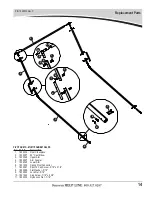

WIRING DIAGRAM

battery

solenoid

circuit

breaker

toggle

switch

direct

-

drive

motor

NOTE:

Refer to

wiring diagram

for steps 3, 4, 5,

6 and 9. See note

and caution on

previous page.

NOTE:

Kit includes 3 extra butt connectors. If excess switch

wire cannot be coiled, connectors are provided to shorten

switch wires to desired length.

+

_

A

T

NOTE:

Be sure to raise housing assembly to fully extended

height before cutting wire to length.

STEP 4:

Crimp two 3/8" ring terminals

6

on one end of wire

and two 1/4" ring terminals

5

on other end. Connect

1/4" ring terminals to motor and 3/8" ring terminals to

solenoid.