3

GENERAL INFORMATION

1. GENERAL INFORMATION

SHAFT-50PRO / 85PRO shaft type electromechanical drive is intended for automation of the balanced industrial section gate. It is pos-

sible to install drive directly on the shaft or by means of intermediate chain gear (option).

The drive consists of the mechanical reducer located in an oil bath, and the electric motor with remote control unit. The reducer and

the engine are made in one case.

1.1. Primary functions

The drive is equipped with automatic stopping system which stops motor operation in the extreme positions quickly and safely.

If the motor does not work, the self-locking reducer provides mechanical blocking of the gate shaft. In case of electric power outage it

is possible to operate gate by means of a reducer chain.

Terminal switches make it possible to ensure safety and reliability of drive operation.

ATTENTION!

Regularly check the adjustment of torsion springs: under the conditions of unadjusted springs unlocking can

produce spontaneous closing of the gate.

In case of emergency, the door can be operated manually using the chain.

ATTENTION!

Use a manual chain without unlocking only in case of emergency; otherwise chain reducer outage is possible.

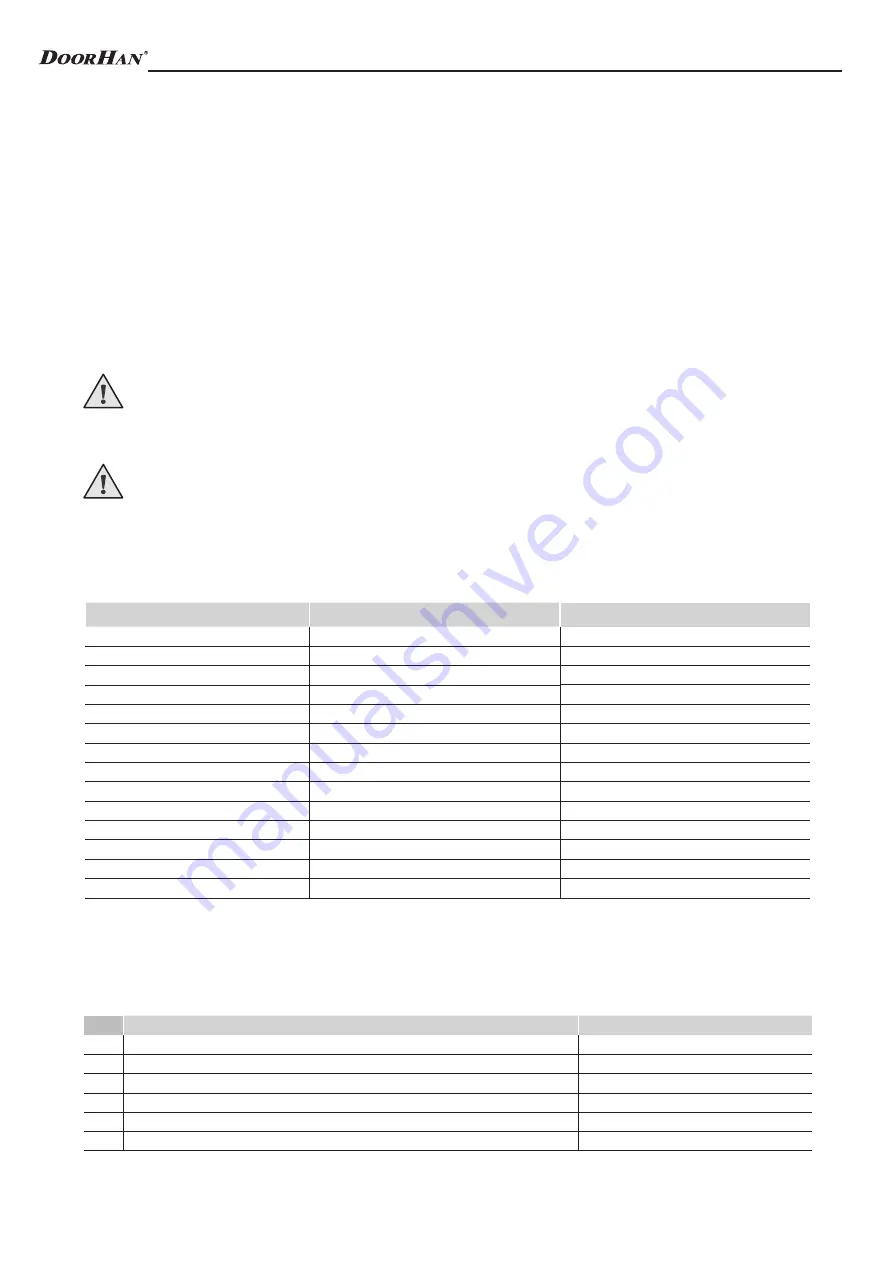

1.2. Specifications

№

Name

Number

1

Drive

1

2

Supporting bracket

1

3

Hardware kit

1

4

Chain of the hand-operate chain drive (8 m)

1

5

External button switch

1

6

User guide

1

1.3. Scope of supply

After receiving the drive it is necessary to unpack and to examine it, and to make sure that drive has no damages. If you found

damages, please, contact the drive supplier.

The details which are included in the standard list of drive equipment are given in the following table.

Characteristic

Parameters SHAFT - 50 PRO

Electric supply

220-240 V/50 Hz

Torque

50 N·m

Rate of motor rotation

1400 rpm

Shaft hole (with key slot)

25.4 mm

Length of hand chain

8 m

Rate of motor rotation

24 rpm

Weight with chain

18 kg

Dimensions

406

×

259

×

115 mm

Thermal protection

130°C

Intensity

65%

Oil amount

0.25 l

Motor capacity

370 W

Protection index

IP54

Operating temperature range

–25…+50°C

Parameters SHAFT - 85 PRO

220-240 V/50 Hz

85 N·m

1400 rpm

25.4 mm

8 m

24 rpm

19kg

416

×

259

×

115 mm

130°C

65%

0.25 l

450 W

IP54

–25…+50°C

Summary of Contents for DRIVE SHAFT-50PRO

Page 16: ...FOR NOTES ...

Page 17: ...FOR NOTES ...

Page 18: ...www doorhan ru www doorhan cn www doorhan com ...