ON

1 2 3 4

1 2 3 4

5

6 7 8 9 10

115 V

A

C

INPUT

J1

P1

RESET

CLEAR

ST

A

T

AUTO OPEN

MOTOR DIR

AC ON ACT

LIMIT

TIMER

BA

TT ST

A

T

RUN

TIME

HEAR

T

BEA

T

TRICKLE

CHARGE

ST

A

T

SW2

ON

1473-010

REVERSE

SENSITIVITY

1601-010

TIME

DELAY

POWER

1

ON

2

3

4

5

6

7

8

1

ON

2

3

4

5

6

7

8

NC

UP

LOOP

DOWN

LOOP

1

2

3 4 5 6 7 8

9

10 11 12 13

14

SW 1

SW 2

LN

V

-

V

+

SUPPLY

GROUND

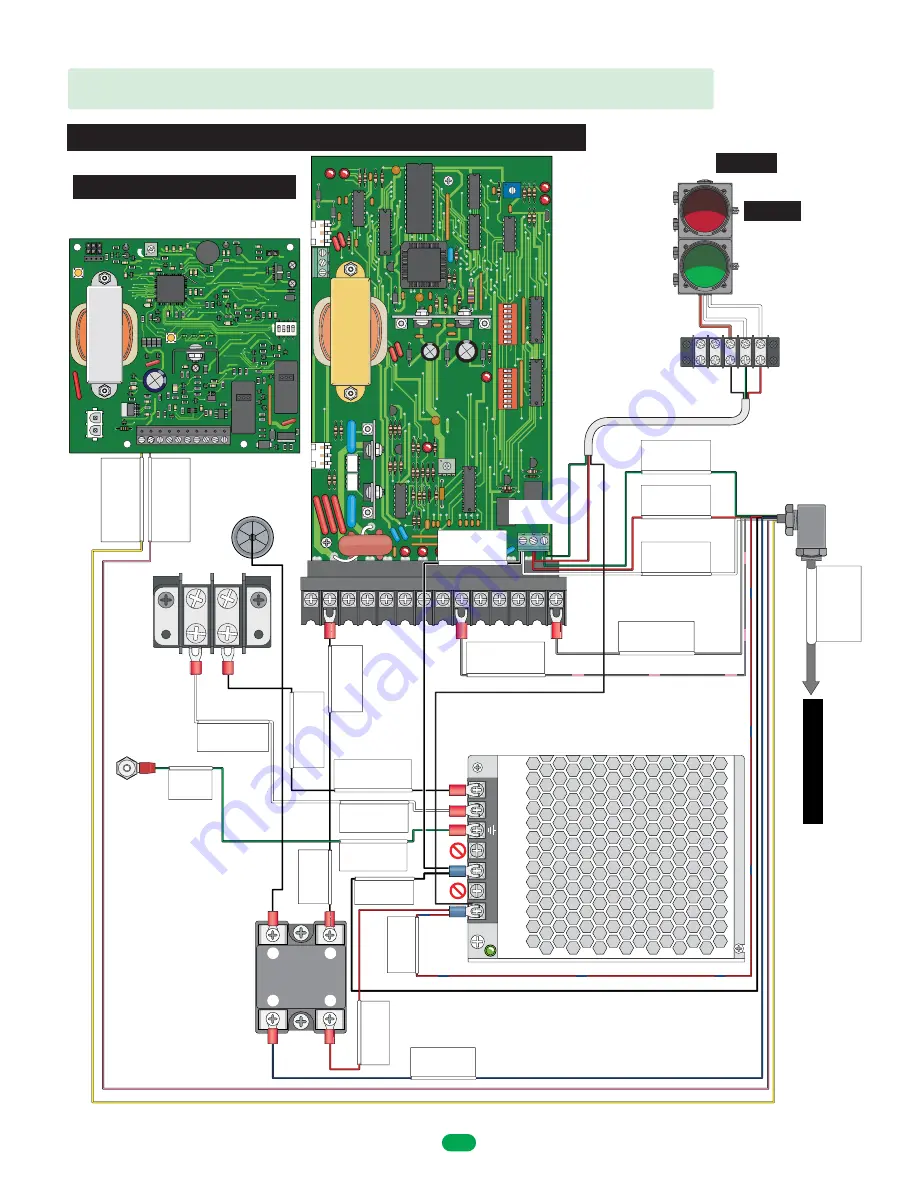

Required

MAKE SURE ALL POWER IS TURNED OFF TO OPERATOR!

OPTIONAL Convenience Open 1473

1601-426 Power Supply 8.

5

A

110V

AC HOT

Solid State Relay

L16

Terminal 2

Main PCB

110V

AC HOT L14

115V Neutral

Terminal Block 2 Position

L20

N - Neutral

Transformer 8.5 amp

L22

L - Line

Transformer 8.5 amp

L21

115V HOT

Te

rminal Block 2 Position

L19

Ground

Transformer 8.5 amp

L23

Ground

Panel Stud

L24

NEU HOT

N-Close

Main PCB

Red Light C1 L1

N-Open

Main PCB

Green Light C2 L2

Common

Main PCB

LED Light C10 L11

Terminal 14

Main PCB

Reverse Edge C4 L4

Terminal 1

Batter

y Backup PCB

Breakaway Sensor NC

C9 L15

Terminal 2

Batter

y Backup PCB

Breakaway Sensor NC

C8 L13

12V Negative (-)

Solid State Relay

C6 L6

12V Positive (+)

Solid State Relay

C3 L3

1

2

4

3

NEG

POS

Relay

NO

NC

C

V-

Transformer 8.5 amp

L18

V+

Tr

ansformer 8.5 amp

L17

Black

White

White

Pink

Blue

Black

Green

Green

Red/Blue

Grey/Pink

Grey

Red

Red

Yellow

Common

Main PCB

12V Neg C7 L12

Terminal 9

Main PCB

Reverse Edge C5 L5

Relay for

Breakaway

Sensors

NOTE:

Will

NOT

work with older model

2340-010 convienence open board

Traffic Light - Black

(to V+ Power Supply)

NO - Open

- Green

NC - Close

- Red

Traffic

Light

Terminal

Traffic Light Cable

Black

Red/

Brown

Green

Red

White

White

Optional

LED Traffic

Light Kit

Sold Separately

Only wire your existing

Optional

components

Arm Relay

Contacts

1601 Octagon Breakaway Arm - Wiring Operator

Remove existing wire

from Main PCB

Terminal 2

and connect it to

Relay #1

To

Arm

See previous page

DoorKing Part Number

1601-295

2

1

1601-356

Harness

8

1601-269-G-7-21