9150-065-Y-12-20

8

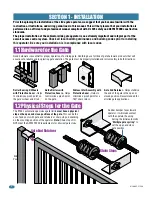

Gate End Retainer

End

Post

SECTION 1 - INSTALLATION

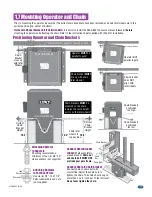

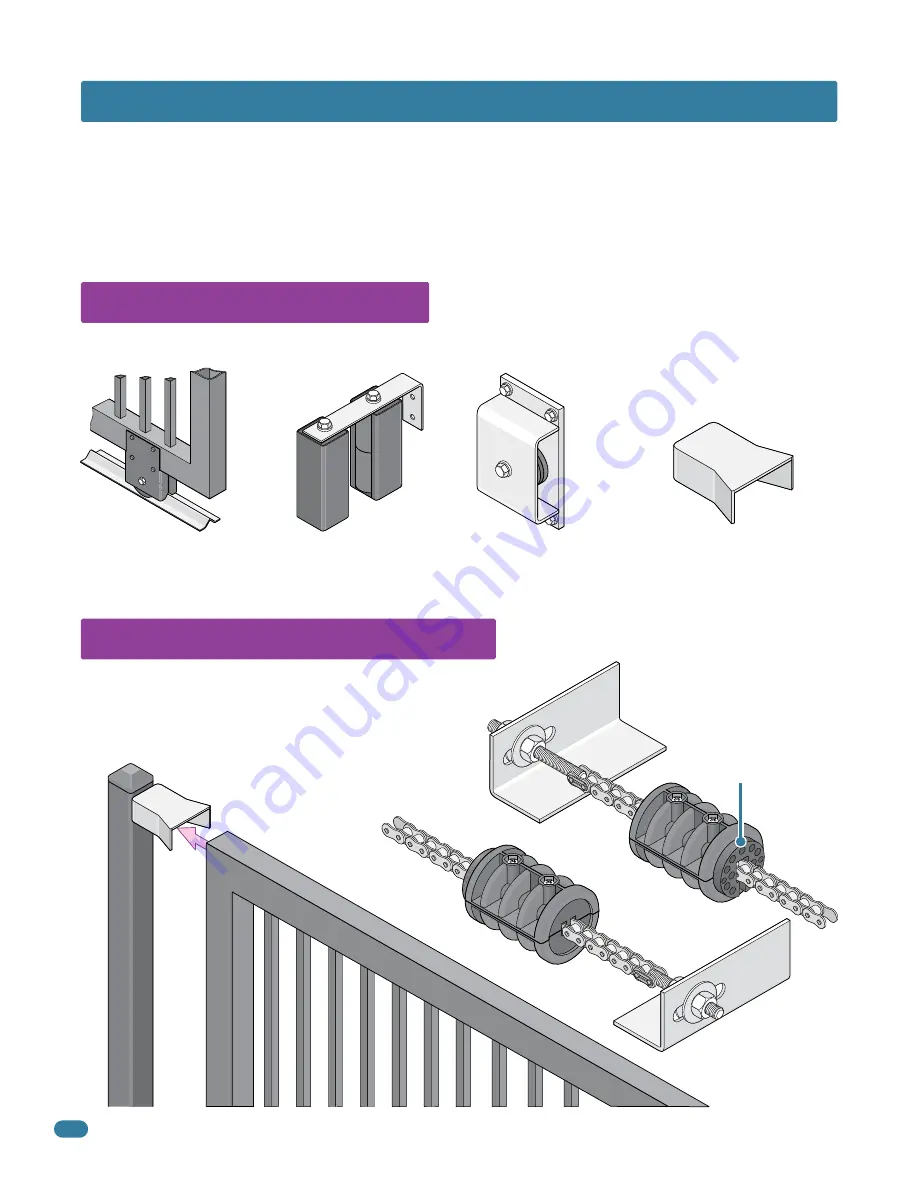

1.2 Physical Stops for the Gate

1.1 Hardware for the Gate

Good hardware is essential for proper operation of a sliding gate. DoorKing has a full line of gate hardware products that will

ensure safe, reliable and long lasting gate operation. The gate must be properly installed and roll smoothly in both directions.

Rubber bumper faces toward

operator. it will make contact

with the operator housing

during the initial automatic

“

Multiple gate cycling”

to

set the open and close

gate position.

The 9150’s automatic open/close gate limits

must have a physical

stop on the open and close positions of the gate

. This can be the

use of end posts with gate end retainers or chain stops, depending

on the mounting position of the operator.

Note:

Chain stops DO

NOT meet the ASTM F2200 requirements for physical gate stops.

Gate End Retainer -

Helps stabilize

the end of the gate in the open or

closed position. Recommended for

all slide gate applications.

Endless Idler Assembly with

Protective Cover -

Helps to

minimize a pinch point for a

180° chain return.

Guide Rollers with

Protective Covers -

Helps

to minimize a pinch point

on the gate.

Roller Bearing V-Wheels

with Protective Cover -

Helps

to minimize a pinch point on

the gate’s wheel and V-rail.

Chain Stops

Gate

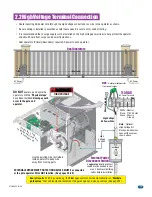

Prior to beginning the installation of the slide gate operator, we suggest that you become familiar with the

instructions, illustrations, and wiring guide-lines in this manual. This will help insure that your installation is

performed in an efficient and professional manner compliant with UL 325 safety and ASTM F2200 construction

standards.

The proper installation of the vehicular slide gate operator is an extremely important and integral part of the

overall access control system.

Check all local building ordinances and building codes prior to installing

this operator. Be sure your installation is in compliance with local codes.