(

24

)

Book: 43214683 (11-21-06) Rev A

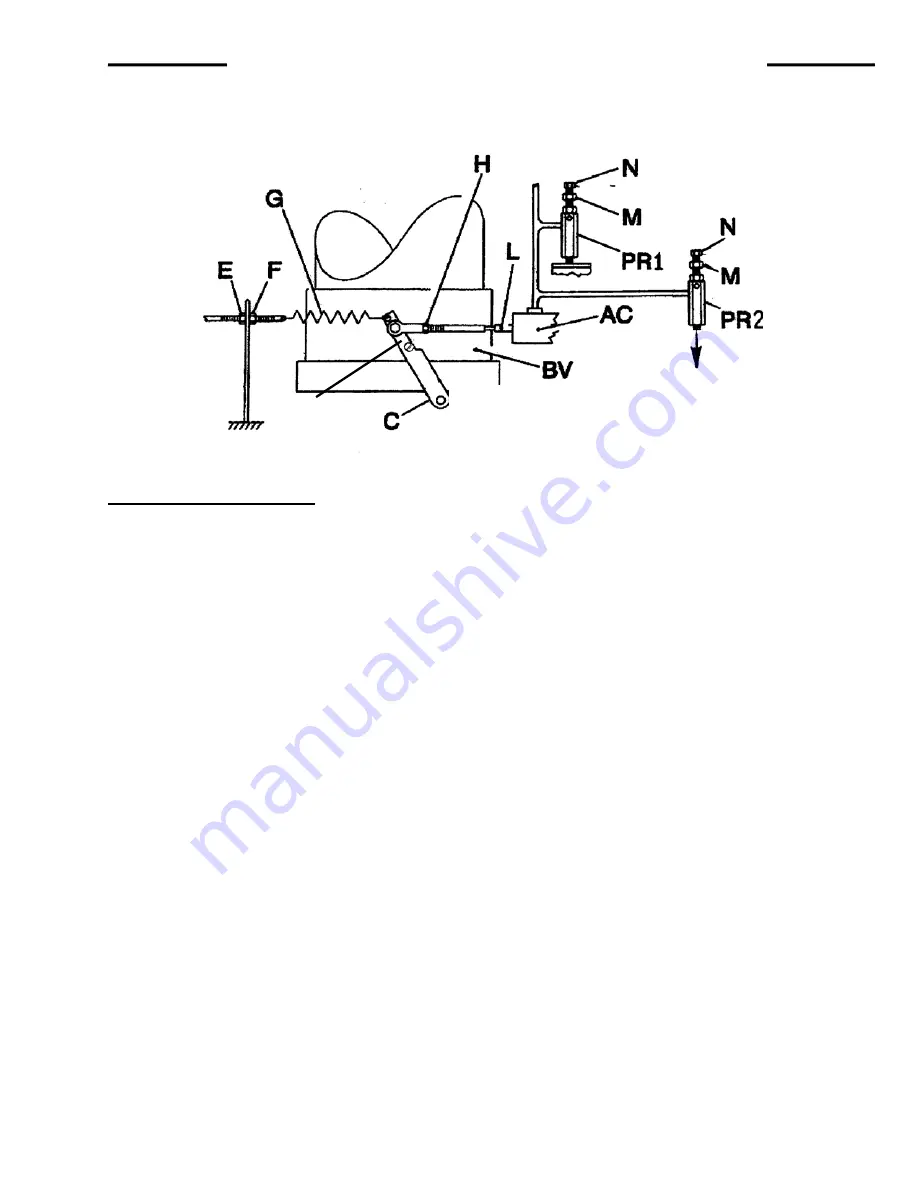

Adjustment Instructions

The operating pressure of this unit was set at

the factory to the maximum rating (at full speed)

See General Data. However, this pressure may

be reset down to 160 psi (1050 kPa)

Normally, regulation requires no adjusting; but if

proper adjustment is lost, proceed as follows:

1. Loosen bolt A. Adjust BFV until scribe mark

on end of BV shaft is 60

°

above horizontal.

Re-tighten A.

2. Loosen nut (E) to relax spring (G).

3. Loosen nut (H). Turn rod (L) in Air Cylinder

(AC) until there is approximately ¾ inch (20

mm) between nut (H) and flats on rod (L).

4. Turn rod (L) one round into rod end bearing.

Tighten nut (H). Rotate butterfly shaft/lever

(C), open and close, several times to assure

that linkage is not binding.

5. Take slack out of spring (G) by moving nuts

(E) and (F). Tighten nuts.

6. Start unit and allow to warm up for 3 to 5

minutes.

7. Activate “Service Air” switch if so equipped.

8. With service air valve closed, adjust

pressure regulator (PR) to rated pressure (*)

plus 10 psi (70kPa) as follows:

9. Loosen locknut (M) counterclockwise. Turn

adjustment cap (N) clockwise to increase

pressure, counterclockwise to decrease

pressure.

10. Bring driver engine to rated speed.

11. Open service air valve until lever C contacts

stop B. Adjust regulator to give rated

operating pressure (*). Tighten locknut (M).

12. To regulate to any pressure between 150

psi (1050kPa) and maximum rating (*),

make adjustments at the pressure regulator.

13. Note: For Dual Regulation –

Unit may be equipped with dual regulation. This

includes a second pressure regulator (PR2) set

at a lower pressure than the PR1.

Setting of

the PR2 must be between 150 and 250 psig.

Repeat steps 9-12 to set PR2 after selecting low

pressure range on customer panel. Any

override needle valve must be closed during this

procedure.

Pressure Regulation Adjusting Instructions

A

Summary of Contents for 083

Page 2: ......

Page 3: ......

Page 4: ......

Page 5: ......

Page 6: ......

Page 7: ......

Page 8: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 71: ......

Page 72: ......

Page 73: ......