11/30/06

FLUIDS AND LUBRICATION TABLE

Ingersoll-Rand

Preferred Fluids

1 gal. (3.8 litre)

5 gal. (19.0 litre)

55 gal. (208.2 litre)

220 gal. (835 litre)

IR Pro-Tec

™

36899698 36899706 36899714 36899722

IR XHP605

-

22252076

22252050

22252068

IR XHP1001

-

35612738

35300516

-

XHP405

-

22252126

22252100

22252118

Engine Oil

54480918

36875938

36866903

If the unit has been operated for 1,000 hours, it should be

completely drained of oil. If the unit has been operated under

adverse conditions or under long shutdown periods, an earlier

change may be necessary as oil deteriorates with time as well

as by operating conditions. Complete replacement of the old oil

with clean oil every 500 to 1,000 hours, depending upon

operating conditions, not only is desirable, but is good insurance

against the accumulation of dirt, sludge or oxidized oil products.

Completely drain the receiver/separator and the piping. If the oil

is drained immediately after the

unit has been run for some time,

most of the sediment will be in suspension and will drain more

readily.

Note:

Shorter oil change intervals may be necessary if unit is

operated under adverse conditions.

Do not, under any circumstances, open any drain cocks, remove

any plugs or the oil filler plug from

the

compressor

lubricating

and cooling oil system without making sure the air receiver

system had been completely relieved of all air pressure.

Some oil mixtures are incompatible with each other and result in

the formation of varnishes, shellacs or lacquers, which may be

insoluble. Such deposits can cause serious trouble including

clogging of the filter. Where possible, try to avoid mixing oils of

the same type but different brands. A brand change is best

made at the time of a complete oil change. Refer to the

Fluids

& Lubrication Table

for oil recommendation.

CAUTION

WARNING

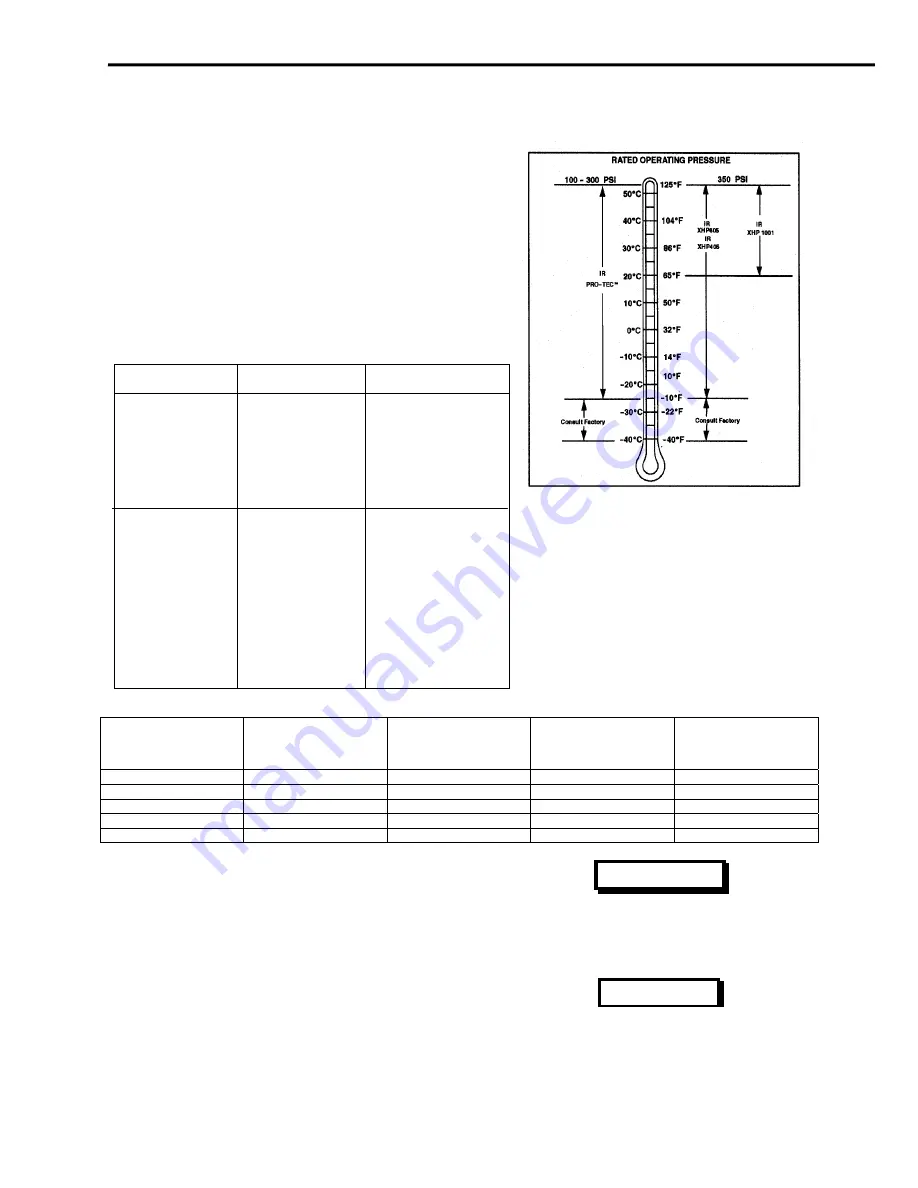

Refer to these charts for correct compressor fluid required.

Note that the selection of fluid is dependent on the design

operating pressure of the machine and the ambient

temperature expected to be encountered before the next

oil change.

Note:

Fluids listed as “preferred” are required for

extended warranty.

Compressor oil carryover (oil consumption) may be

greater with the use of alternative fluids.

Design Operating

Pressure

Ambient

Temperature

Specification

100 psi to 300 psi

350 psi

-10

°

F to 125

°

F

(-23

°

C to 52

°

C)

-23

°

C to 52

°

C

(-10

°

F to 125

°

F)

65

°

F to 125

°

F

(18

°

C to 52

°

C)

Preferred:

IR Pro-Tec

™

Alternate: ISO Viscosity

Grade 46 with rust and

oxidation inhibitors,

designed for air

compressor service.

Preferred:

IR XHP605

Alternate: IR XHP405

ISO Viscosity Grade 68

Group 3 or 5 with rust

and oxidation inhibitors,

designed for air

compressor service.

Preferred:

IR XHP605

IR XHP1001

Preferred Ingersoll-Rand Fluids –

Use

of these fluids with original I-R filters can

extend warranty. Refer to operator’s

manual warranty section for details or

contact your I-R representative.

Summary of Contents for 083

Page 2: ......

Page 3: ......

Page 4: ......

Page 5: ......

Page 6: ......

Page 7: ......

Page 8: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 71: ......

Page 72: ......

Page 73: ......