100

OPTIONS

7/124 - 10/104, 10/124 - 14/114, 14/84

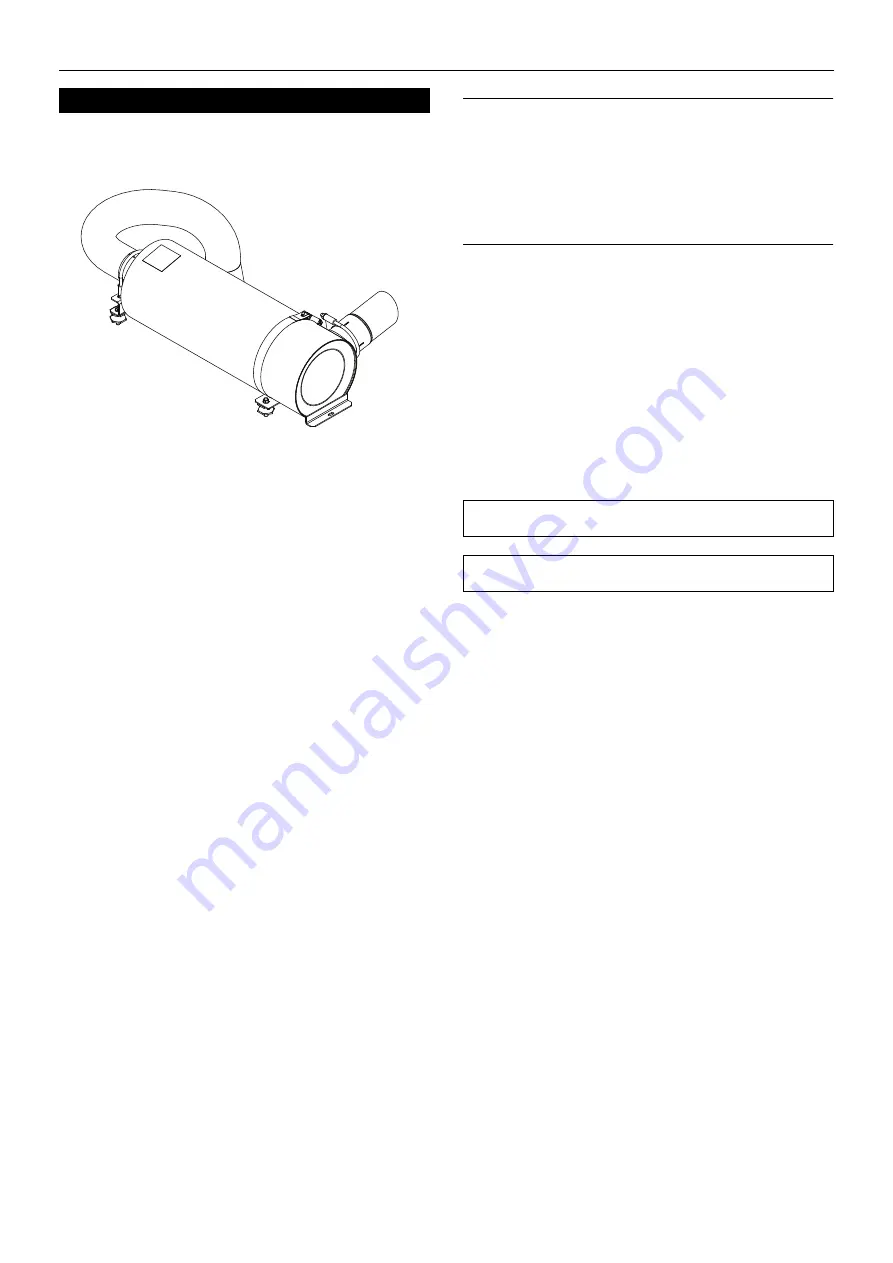

DESCRIPTION

Diesel Engine exhaust spark arrestors are a key safety feature for both

hazardous area and lower risk diesel engine applications where a stray

spark may cause ignition of combustible material. Virtually all

legislation regarding the operation of a diesel engine in a hazardous

area includes a mandatory requirement to fit a tested and approved

exhaust spark arrestor.

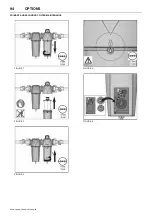

MAINTENANCE

Daily:

Examine the spark arrestor for any sign of gas leakage, cracks or

significant areas of damage, i.e. dents of more than a few millimetres

in depth.

Three Monthly:

Remove spark arrestor. Tap with a soft mallet to loosen any internal

deposits and shake out. Also by shaking check for any loose internal

baffles.

Six Monthly (or 1500 hours operation, whichever is sooner):

Examine the exhaust discharge in darkness whilst repeatedly loading

and accelerating the engine. If any sparks are observed, the spark

arrestor is not suitable for further use.

OPTION - SPARK ARRESTOR

T6361_00

WARNING: Ensure adequate ventilation if this check is carried

out in an enclosed area.

WARNING: The engine must not be put back into service until

any problems identified by the above checks are rectified.

Summary of Contents for 10/104

Page 2: ......

Page 4: ......

Page 11: ...ISO SYMBOLS 7 7 124 10 104 10 124 14 114 14 84 Replace any cracked protective shield ...

Page 83: ...MAINTENANCE 79 7 124 10 104 10 124 14 114 14 84 ...

Page 84: ...80 MAINTENANCE 7 124 10 104 10 124 14 114 14 84 ...

Page 92: ...88 MACHINE SYSTEMS 7 124 10 104 10 124 14 114 14 84 ...

Page 108: ......

Page 109: ......