16

OPERATING INSTRUCTIONS

7/124 - 10/104, 10/124 - 14/114, 14/84

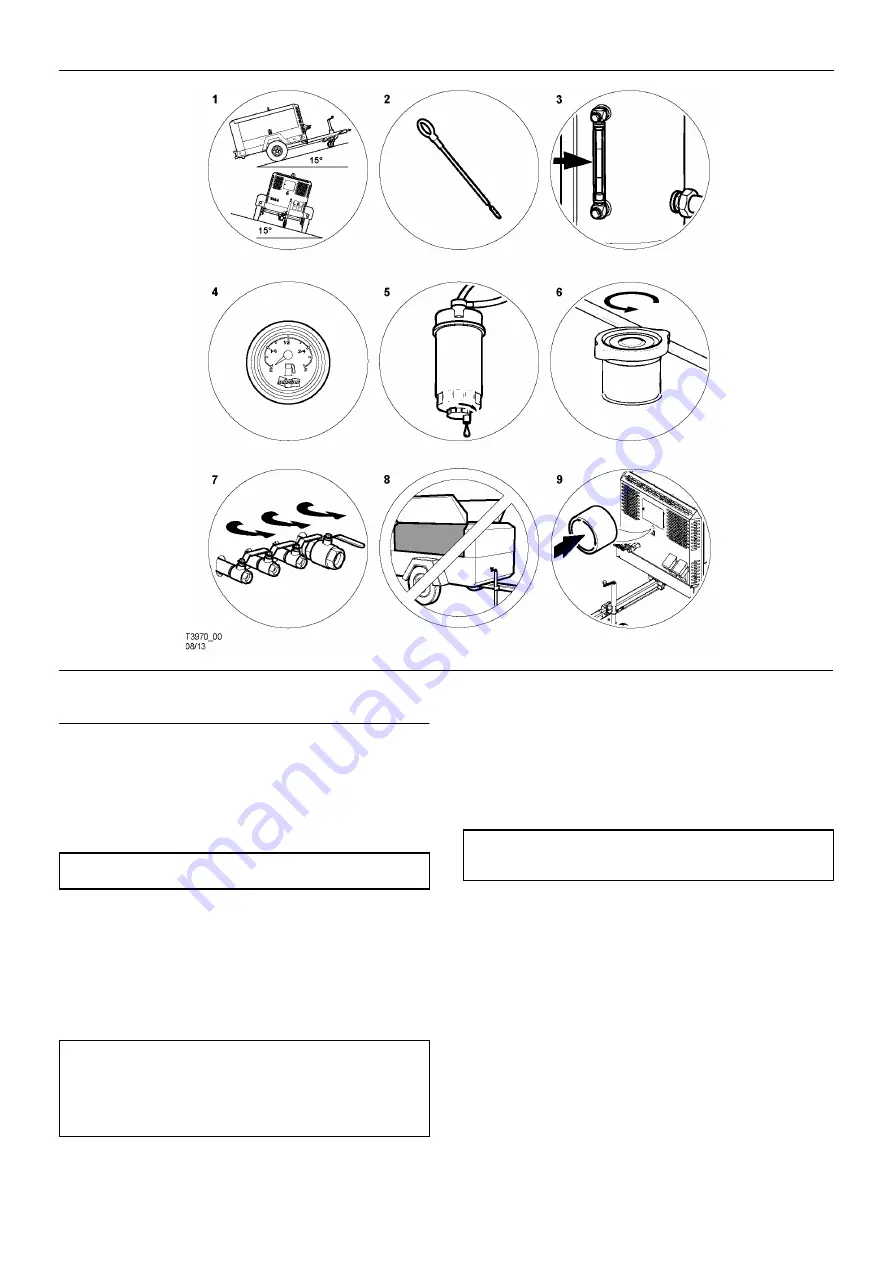

PRIOR TO STARTING

1. Place the unit in a position that is as level as possible. The design

of the unit permits a 15 degree lengthways and sideways limit on

out of level operation. It is the engine, not the compressor, that is

the limiting factor.

When the unit has to be operated out of level, it is important to keep the

engine oil level near the high level mark (with the unit level).

2. Check the engine lubrication oil in accordance with the operating

instructions in the

Engine Operator’s Manual.

3. Check the compressor oil level in the sight glass located on the

separator tank.

4. Check the diesel fuel level. A good rule is to top up at the end of

each working day. This prevents condensation from occurring in the

tank.

5. Drain the fuel filter water separator of water, ensuring that any

released fuel is safely contained.

6. Check the radiator coolant level (with the unit level).

7. Open the service valve(s) to ensure that all pressure is relieved

from the system. Close the service valve(s) when all pressure is

relieved.

9. Check that the emergency stop switch is not engaged. Pull knob to

release if necessary.

10.Close the manual relief valve inside the unit, on the top of the

separator tank.

When starting or operating the machine in temperatures below or

approaching 0°C (32°F), ensure that the operation of the regulation

system, the unloader valve, the safety valve, and the engine are not

impaired by ice or snow, and that all inlet and outlet pipes and ducts

are clear of ice and snow.

CAUTION:

Do not overfill either the engine or the compressor with

oil.

CAUTION:

When refuelling:-

•

switch off the engine.

•

do not smoke.

•

extinguish all naked lights.

•

do not allow the fuel to come into contact with hot surfaces.

•

wear personal protective equipment.

8.

CAUTION:

Do not operate the machine with the canopy/doors in

the open position as this may cause overheating and operators to

be exposed to high noise levels.

Summary of Contents for 10/104

Page 2: ......

Page 4: ......

Page 11: ...ISO SYMBOLS 7 7 124 10 104 10 124 14 114 14 84 Replace any cracked protective shield ...

Page 83: ...MAINTENANCE 79 7 124 10 104 10 124 14 114 14 84 ...

Page 84: ...80 MAINTENANCE 7 124 10 104 10 124 14 114 14 84 ...

Page 92: ...88 MACHINE SYSTEMS 7 124 10 104 10 124 14 114 14 84 ...

Page 108: ......

Page 109: ......