54

OPERATING INSTRUCTIONS

7/124 - 10/104, 10/124 - 14/114, 14/84

2. Diesel Exhaust Fluid (DEF) Lamp

•

The Diesel Exhaust Fluid Lamp alerts the operator that the DEF is

low and SHOULD be replenished.

•

When DEF level drops below 10% the DEF lamp illuminates. The

operator should now add DEF fluid.

•

When DEF level drops below 5% the DEF lamp starts flashing. The

engine power will de-rate to 25% which may cause the unit to shut

off due to engine over load.

•

When DEF level drops to 0% the DEF lamp continues flashing and

the engine will stop repeatedly.

•

When the machine is started again it is not possible to switch unit to

full load and engine runs at idle speed.

•

Refill at least 50% of DEF tank volume. After 3 minutes DEF tank

gauge level will show actual tank volume and red DEF lamp goes

OFF.

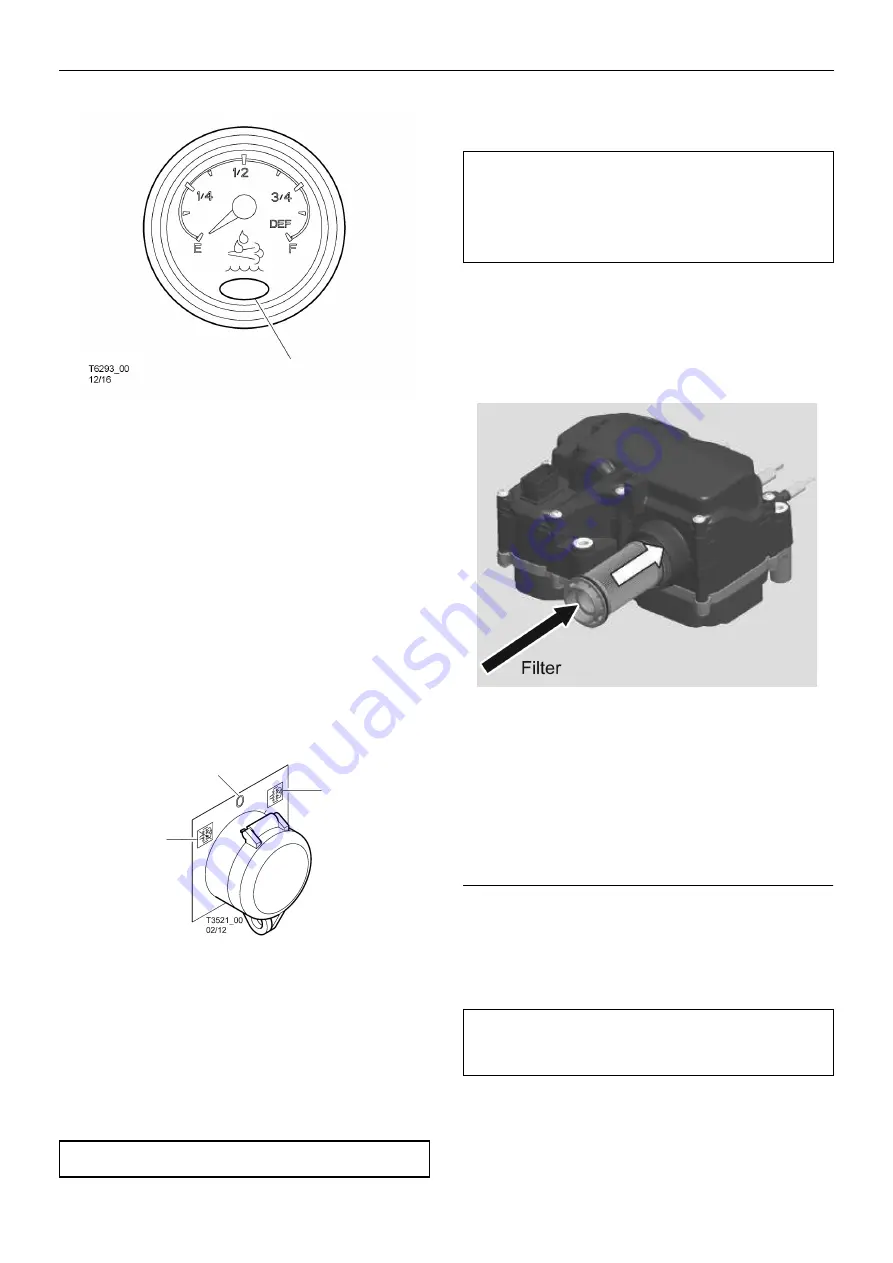

Exhaust System Cleaning Switch

The exhaust system cleaning switch provides operator control of the

exhaust cleaning system. When the switch is turned to the NORMAL

position (0), the engine ECM will automatically perform the exhaust

system cleaning when required. When the switch is turned to the

INITIATE position (Right), a request is sent to the engine ECM for a

manual cleaning of the exhaust system.

This manual cleaning will only happen when the engine ECM

determines conditions for cleaning are met. When the switch is turned

to the DISABLE position (Left), the engine ECM disallows any

automatic or manual (non-mission) cleaning of the exhaust system.

When the switch is turned to the DISABLE position (Left), the engine

ECM disallows any automatic or manual (non-mission) cleaning of the

exhaust system.

Important Notes:

The DOC is a maintenance free device and will under normal

conditions remain operational for as long as the engine.

The DEF system requires maintenance of the filter situated in the

Bosch dosing pump at the required intervals (see scheduled

maintenance).

Using any fluid other then the proper DEF fluid will contaminate and

render the dosing system inoperable causing the engine to stop.

Should any contamination occur, then the tank needs to be removed

and cleaned before filling with the correct DEF fluid.

DEF fluid should only be used from clean receptacles or filtered

pumping systems.

Never use additives to change the DEF fluid properties.

AFTERTREATMENT PROTECTION AFFECTING COMPRESSOR

OPERATION

DEF Quality

Adequate DEF quality is essential to meet emission targets. If an issue

with the DEF quality is detected the system will warn the operator of

the issue by the use of warning lights. If the warnings are ignored the

engine derate will apply, resulting in lower compressor flow output.

DEF Equipment Tampering

When any hardware or performance issues cause the NOx emissions

to exceed the legislated limits, the operator is warned with the

respective engine fault codes. If the warnings are ignored, the

inducements will start.

NOTE:

Switch returns from INITIATE position to NORMAL position

automatically.

low level DEF lamp

NORMAL position

DISABLE position

INITIATE position

WARNING: Continued use of the Exhaust System Cleaning

Inhibit position will at first lead to warning messages being

displayed on the Midport. Failure to respond with a return to the

Normal switch position will eventually create a severe engine

power derate and shutdown, running in this condition until

shutdown could also damage the SCR core requiring

replacement instead of cleaning.

WARNING: The ultimate engine protection level will be activated

after several restarts with the incorrect DEF quality in the DEF

tank and requires a Cummins technician to reset protection

parameters to allow engine restart.

Summary of Contents for 10/104

Page 2: ......

Page 4: ......

Page 11: ...ISO SYMBOLS 7 7 124 10 104 10 124 14 114 14 84 Replace any cracked protective shield ...

Page 83: ...MAINTENANCE 79 7 124 10 104 10 124 14 114 14 84 ...

Page 84: ...80 MAINTENANCE 7 124 10 104 10 124 14 114 14 84 ...

Page 92: ...88 MACHINE SYSTEMS 7 124 10 104 10 124 14 114 14 84 ...

Page 108: ......

Page 109: ......