OPERATING INSTRUCTIONS

55

7/124 - 10/104, 10/124 - 14/114, 14/84

Tampering/Malfunction events include, but are not limited to:

•

Disconnected tank level and/or quality sensor.

•

Blocked DEF line or dosing unit.

•

Disconnected DEF dosing unit.

•

Disconnected DEF pump.

•

Disconnected SCR Wiring Harness.

•

Disconnected NOx Sensor.

•

EGR Valve malfunction.

•

Disconnected coolant level sensor.

•

Any hardware or performance issues that will cause the NOx

emission exceeding a legislated threshold.

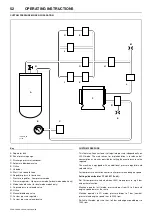

Remote DEF Refilling (optional)

For units that have optional remote DEF filling, the feature is functional

after connecting with an external DEF tank if the main power switch is

in the “ON” position.

The DEF can be refilled either by gravity feed from an elevated external

DEF tank, or by an external pump controlled by the on-board ECU. The

pump must be connected via TB101 signal terminals (NO / NC / GND)

and must meet the following specification:

•

Power supply: Maximum 15 A or appropriate relay must be added.

•

Flow rate: Maximum 34 l/min.

•

Maximum static pressure at closed outlet: 2 bar.

•

Pump must be equipped with a bypass valve.

If the DEF level drops below 20%, the solenoid valve behind the quick

coupling opens and switches on the contacts for the external pump.

The internal DEF tank is refilled from the external tank until the DEF

level reaches 80%.

DECOMMISSIONING

When the machine is to be permanently decommissioned or

dismantled, it is important to ensure that all hazard risks are either

eliminated or notified to the recipient of the machine. In particular:-

•

Do not destroy batteries or components containing asbestos

without containing the materials safely.

•

Do not dispose of any pressure vessel that is not clearly marked

with its relevant data plate information or rendered unusable by

drilling, cutting etc.

•

Do not allow lubricants or coolants to be released into land surfaces

or drains.

•

Do not dispose of a complete machine without documentation

relating to instructions for its use.

LONG TERM STORAGE RECOMMENDATIONS

(6 months or more)

Spare Airends

•

Long-term storage of airends should include filling the airend with

the standard compressor fluid, PRO-TEC, XHP605 or XHP405.

Upon installation of the airend, drain the storage oil from the airend

and proceed with the installation, assuring fresh oil is poured into

the intake prior to start up.

Portable Compressors

•

Airend – Remove the intake connection and pour the airend intake

full with Doosan compressor fluid PRO-TEC, XHP605 or XHP405.

Reconnect the intake connection.

•

Engine cooling system – Treat with rust inhibitor and drain. Check

with engine dealer for further recommendations.

•

Compressor Oil Filter/s- fill with Doosan compressor fluid PRO-

TEC, XHP605 or XHP405.

•

Seal all opening with waterproof tape

•

Place a desiccant in the exhaust pipes, engine and compressor air

intake pipes.

•

Loosen tension on belts, fan, airend, etc.

•

Block axles so tyres are off ground and do not support any weight.

•

Disconnect battery cables.

•

Drain fuel system.

SHORT TERM STORAGE

Machines that stand idle for extended periods of time greater than

30 days:

•

Start and operate the machine every 30 days. Operate long enough

to allow the engine and compressor to reach operating

temperature.

•

Open and close the service valve to exercise machine from full load

to idle RPM.

•

Drain fuel tank to remove any water.

•

Drain water from fuel water separator.

WARNING: The ultimate engine protection level will be activated

after several restarts with tampering uncorrected and may

require a Cummins technician to reset protection parameters to

allow engine restart.

NOTE: For fully automatic refilling functionality, the machine

has to run without any errors.

Summary of Contents for 10/104

Page 2: ......

Page 4: ......

Page 11: ...ISO SYMBOLS 7 7 124 10 104 10 124 14 114 14 84 Replace any cracked protective shield ...

Page 83: ...MAINTENANCE 79 7 124 10 104 10 124 14 114 14 84 ...

Page 84: ...80 MAINTENANCE 7 124 10 104 10 124 14 114 14 84 ...

Page 92: ...88 MACHINE SYSTEMS 7 124 10 104 10 124 14 114 14 84 ...

Page 108: ......

Page 109: ......