58

MAINTENANCE

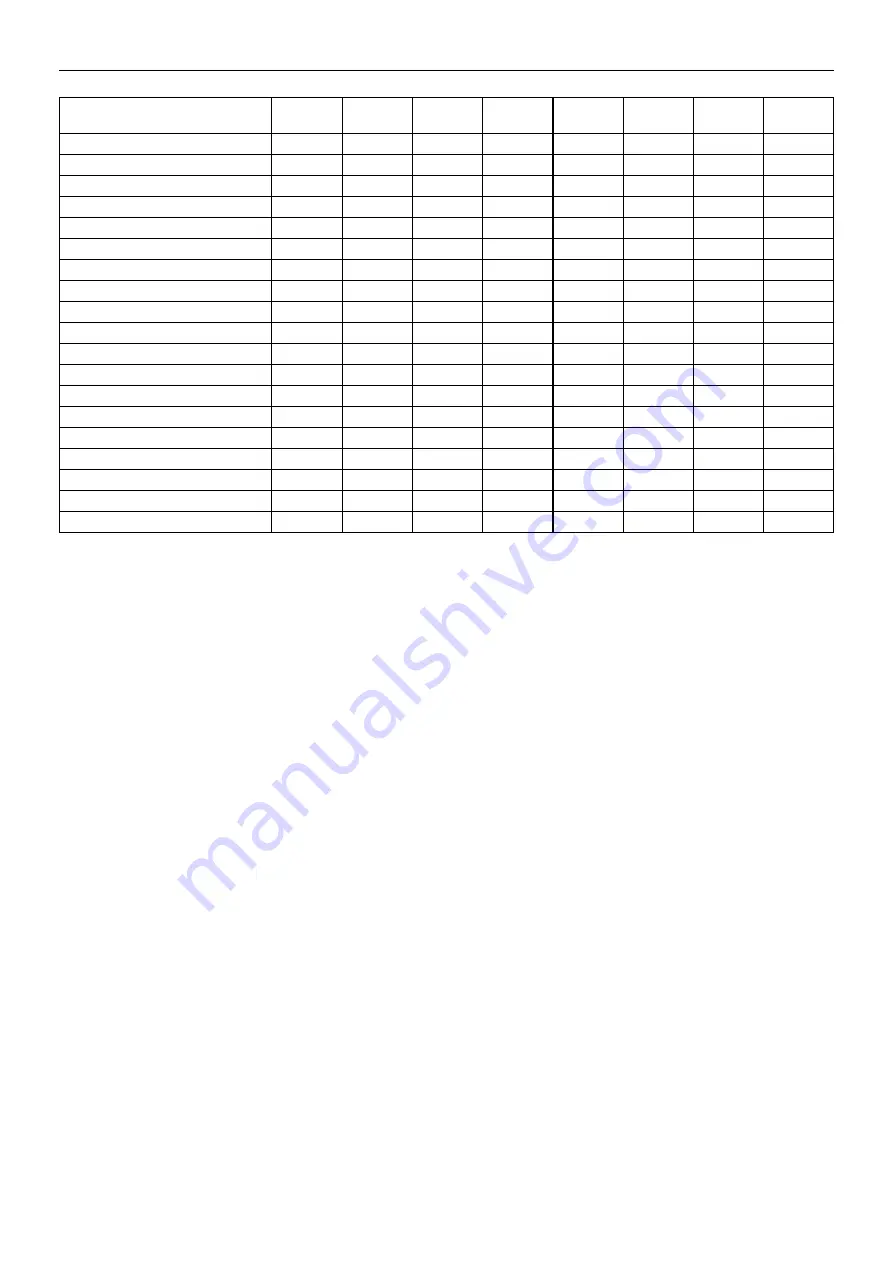

7/124 - 10/104, 10/124 - 14/114, 14/84

* Disregard if not appropriate for this particular compressor

(1) or 3000 miles/5000km whichever is the sooner

C = Check and act if required

T = Test

D = Drain

R = Replace

R/WI = Replace or when indicated earlier

CBT = Check before towing

C/R = Check and replace if required

G/C = Grease and check

C/A = Check and adjust if required

NOTE:

500 and 1000 hour intervals are meant to be repeated at every

500 or 1000 hours. Other intervals only to be performed at hours

indicated.

NOTE:

All fluid and filter intervals are valid for near perfect conditions

only. High ambient temperatures - high dust concentration - high

humidity as well as using lower grade oils and fuels will require a

decrease in maintenance intervals.

Contact your Doosan Infracore Portable Power dealer for more

information or assistance in determining the optimum intervals for your

application.

Daily

Weekly

Monthly

6 months

or 500 hrs

1 year or

1000 hrs

2000 hrs

4500 hrs

5000 hrs

Wheels (Bearings, Seals, etc.)

C

Shutdown Switch Settings

T

Scavenger Orifice & Related

C

Lights (Brake, Running & Turn)

CBT

Pintle Eye Bolts

CBT

Brakes

C

C

Brake Linkage

C

Emergency Stop

T

Fasteners

C

Running Gear Linkage & Bolts

G/C

Safety Valve

C

Minimum Pressure Valve

C

Pressure System

C

Pressure Gauge

C

Pressure Regulator

C

Separator Tank Exterior

C

Lubricator (Fill)

C

Engine Air Inlet Shutdown Valve

C

Engine Vibration Damper

C/R

Summary of Contents for 10/104

Page 2: ......

Page 4: ......

Page 11: ...ISO SYMBOLS 7 7 124 10 104 10 124 14 114 14 84 Replace any cracked protective shield ...

Page 83: ...MAINTENANCE 79 7 124 10 104 10 124 14 114 14 84 ...

Page 84: ...80 MAINTENANCE 7 124 10 104 10 124 14 114 14 84 ...

Page 92: ...88 MACHINE SYSTEMS 7 124 10 104 10 124 14 114 14 84 ...

Page 108: ......

Page 109: ......