62

MAINTENANCE

7/124 - 10/104, 10/124 - 14/114, 14/84

VENTILATION

Always check that the air inlets and outlets are clear of debris etc.

COOLING FAN DRIVE

Periodically check that the fan mounting bolt in the fan hub has not

loosened. If, for any reason, it becomes necessary to remove the fan

or re-tighten the fan mounting bolt, apply a good grade of commercially

available thread locking compound to the bolt threads and tighten to

the torque value shown in the TORQUE SETTING TABLE later in this

section.

This compressor is equipped with a variable speed fan clutch that

requires no periodic maintenance.

The fan belt(s) should be checked regularly for wear and correct

tensioning.

FUEL SYSTEM

The fuel tank should be filled daily or every eight hours. To minimise

condensation in the fuel tank(s), it is advisable to top up after the

machine is shut down or at the end of each working day. At six month

intervals drain any sediment or condensate that may have

accumulated in the tank(s).

FUEL FILTER MAINTENANCE

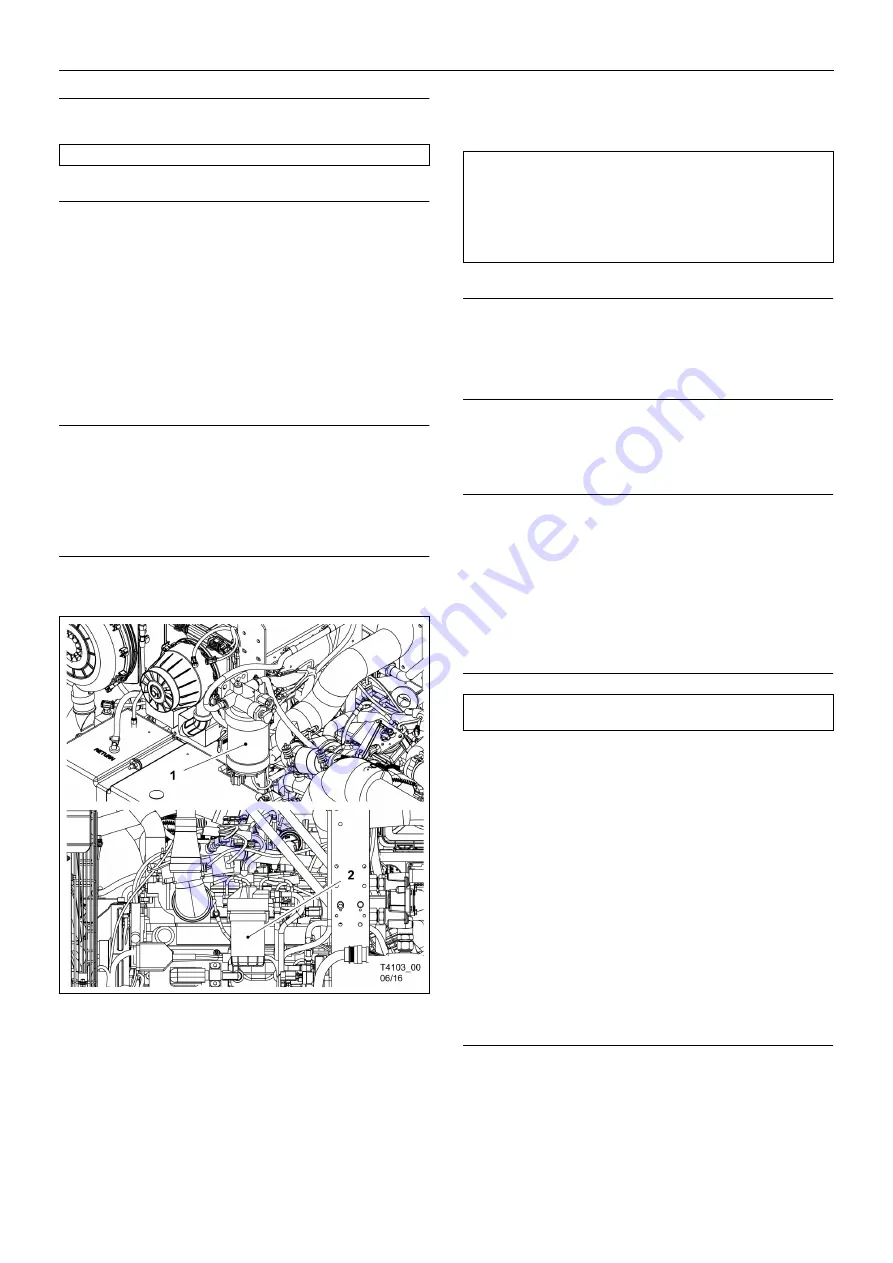

This compressor is equipped with 2 fuel filters in series to be replaced

at every 500 hour interval or sooner if required.

1. Fuel Filter / Water Separator (10 microns).

2. Final Fuel Filter / Water Separator (3 microns).

Fuel Filter / Water Separator

Mounted to the DEF module bracket, this filter is capable of separating

water from fuel and will filter solid contaminants to 10 microns in size.

Replace:

Remove the Water In Fuel sensor connector from the bottom

of the filter element, remove and discard the filter. Install a new element

taking care all seals are in place, install the sensor connector.

Final Fuel Filter / Water Separator

The final fuel filter (3 micron) is mounted on the engine. For

maintenance details, refer to the engine manual.

FUEL FILTER WATER SEPARATOR

The fuel filter water separator contains a filter element which should be

replaced at regular intervals (see the SERVICE/MAINTENANCE

CHART).

CHARGE COOLER PIPEWORK

Inspect all hoses and clips on the charge cooler pipe work.

Engine damage will occur if the charge cooling system leaks.

HOSES

All components of the engine cooling air intake system should be

checked periodically to keep the engine at peak efficiency.

At the recommended intervals, (see the SERVICE/MAINTENANCE

CHART), inspect all of the intake lines to the air filter, and all flexible

hoses used for air lines, oil lines and fuel lines.

Periodically inspect all pipework for cracks, leaks, etc. and replace

immediately if damaged.

ELECTRICAL SYSTEM

When removing connectors from electrical devices and sensors,

inspect the terminals to ensure they have electrical grease on them. If

electrical grease is not present or very minimal, then add a small

amount of electrical grease (Doosan Part No. 22409114) to the

terminals. Dirty and or corroded electrical terminals can be cleaned

using electrical contact cleaner.

Inspect the safety shutdown system switches and the instrument panel

relay contacts for evidence of arcing and pitting. Clean where

necessary.

Check the mechanical action of the components.

Check the security of electrical terminals on the switches and relays i.e.

nuts or screws loose, which may cause local hot spot oxidation.

Inspect the components and wiring for signs of overheating i.e.

discolouration, charring of cables, deformation of parts, acrid smells

and blistered paint.

BATTERY

Keep the battery terminals and cable clamps clean and lightly coated

with petroleum jelly to prevent corrosion.

The retaining clamp should be kept tight enough to prevent the battery

from moving.

CAUTION:

NEVER clean by blowing air inwards.

WARNING: The Primary as well as Secondary filter elements

may be filled with the appropriate quality of fuel from a clean

source. NEVER fill the Final fuel filter before installing.

The correct procedure would be to fill Primary and Secondary

filters with clean fuel, leave the Final filter empty and prime the

system using the hand prime pump on the Primary filter head.

WARNING: Always disconnect the battery switch before

performing any maintenance or service.

Summary of Contents for 10/104

Page 2: ......

Page 4: ......

Page 11: ...ISO SYMBOLS 7 7 124 10 104 10 124 14 114 14 84 Replace any cracked protective shield ...

Page 83: ...MAINTENANCE 79 7 124 10 104 10 124 14 114 14 84 ...

Page 84: ...80 MAINTENANCE 7 124 10 104 10 124 14 114 14 84 ...

Page 92: ...88 MACHINE SYSTEMS 7 124 10 104 10 124 14 114 14 84 ...

Page 108: ......

Page 109: ......