MAINTENANCE

65

7/124 - 10/104, 10/124 - 14/114, 14/84

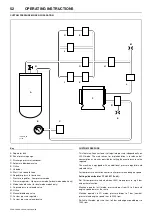

Check the position of the hand brake lever [1]. The start of resistance

should be approximately 10-15mm above the horizontal position.

Check that the wheels move freely when the handbrake is disengaged.

Final test

Check the fasteners on the transmission system (cables, brake

equalisation system and linkage).

Check the handbrake cable [5] for a small amount of play and adjust if

necessary (Variable height only)

Check the compression spring [9] for pre-tensioning.

Test run

If necessary carry out 2-3 test brake actions.

Test brake action

Check the play in brake linkage [7] and if necessary adjust the length

of brake linkage [7] until there is no play.

Apply the handbrake while rolling the machine forward, travel of the

handbrake lever up to

2

/

3

of maximum is allowed.

RE-ADJUSTING THE OVERRUN BRAKING SYSTEM

(KNOTT RUNNING GEAR)

Re-adjustment of the wheel brakes will compensate for brake lining

wear. Follow the procedure described in

2: Brake Shoe Adjustment.

Check the play in the brake linkage [7] and re-adjust if necessary.

Important

Check the brake actuators and cables [11]. The brake actuators must

not be pre-tensioned.

Excessive operation of the handbrake lever, which may have been

caused by worn brake linings, must not be corrected by re-adjusting

(shortening) the brake linkage [7]

Re-adjustment

The handbrake lever [1] should be engaged forcefully several times to

set the braking system.

Check the setting of the brake equalisation assembly [8], which should

be at right angles to the pulling direction.

Check the play in the brake linkage [7] again, ensuring that there is no

play in the brake linkage and that it is adjusted without pre-tension

Check the position of the hand brake lever [1], cable [5] (with little play)

and the compression spring [9] (only slight pre-tension). The start of

resistance of the handbrake lever should be approximately 10-15mm

above the horizontal position.

Final test

Check the fasteners on the transmission system (cables, brake

equalisation system and linkage)

Apply the handbrake while rolling the machine forward, travel of the

handbrake lever up to

2

/

3

of maximum is allowed.

Check the handbrake cable [5] for a small amount of play and adjust if

necessary (Variable height only)

Check the compression spring [9] for slight pre-tensioning.

Summary of Contents for 10/104

Page 2: ......

Page 4: ......

Page 11: ...ISO SYMBOLS 7 7 124 10 104 10 124 14 114 14 84 Replace any cracked protective shield ...

Page 83: ...MAINTENANCE 79 7 124 10 104 10 124 14 114 14 84 ...

Page 84: ...80 MAINTENANCE 7 124 10 104 10 124 14 114 14 84 ...

Page 92: ...88 MACHINE SYSTEMS 7 124 10 104 10 124 14 114 14 84 ...

Page 108: ......

Page 109: ......