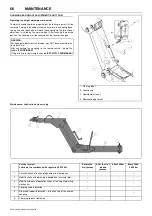

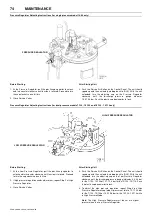

MAINTENANCE

71

7/124 - 10/104, 10/124 - 14/114, 14/84

Lubrication points

Lubricants

<N1>

Lubricate with 5g SPHEEROL EPL2 lubricant or equivalent

NLGI 2 Grade lubricant.

<N2>

Using a brush, cloth or plastic sponge, apply a thin, even layer of

OPTIMOL OLISTAMOLY 2 lubricant or equivalent MoS2 based high

performance grease.

<N3>

Using a brush, apply a thin, even layer of SPHEEROL EPL2 or

equivalent NLGI 2 Grade lubricant.

.

Part to be lubricated

a

Grease nipple

b

Bush

c

Piston rod

d

Hole

e

Top middle part

f

Bottom middle part

g

Holes for handbrake

h

Drawbar coupling

i

Conversion lever coupling

j

Tube

k

Pin

l

Adjustment bolt, welded

m

Gearing

n

Top spindle

o

Thread

p

Bottom spindle

q

Adjustment nut, welded

r

Area

s

Pin of handbrake

t

Seal ring

u

Contact area

v

Screw

w

Guiding slot

Summary of Contents for 10/104

Page 2: ......

Page 4: ......

Page 11: ...ISO SYMBOLS 7 7 124 10 104 10 124 14 114 14 84 Replace any cracked protective shield ...

Page 83: ...MAINTENANCE 79 7 124 10 104 10 124 14 114 14 84 ...

Page 84: ...80 MAINTENANCE 7 124 10 104 10 124 14 114 14 84 ...

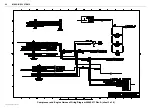

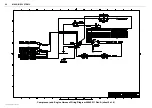

Page 92: ...88 MACHINE SYSTEMS 7 124 10 104 10 124 14 114 14 84 ...

Page 108: ......

Page 109: ......