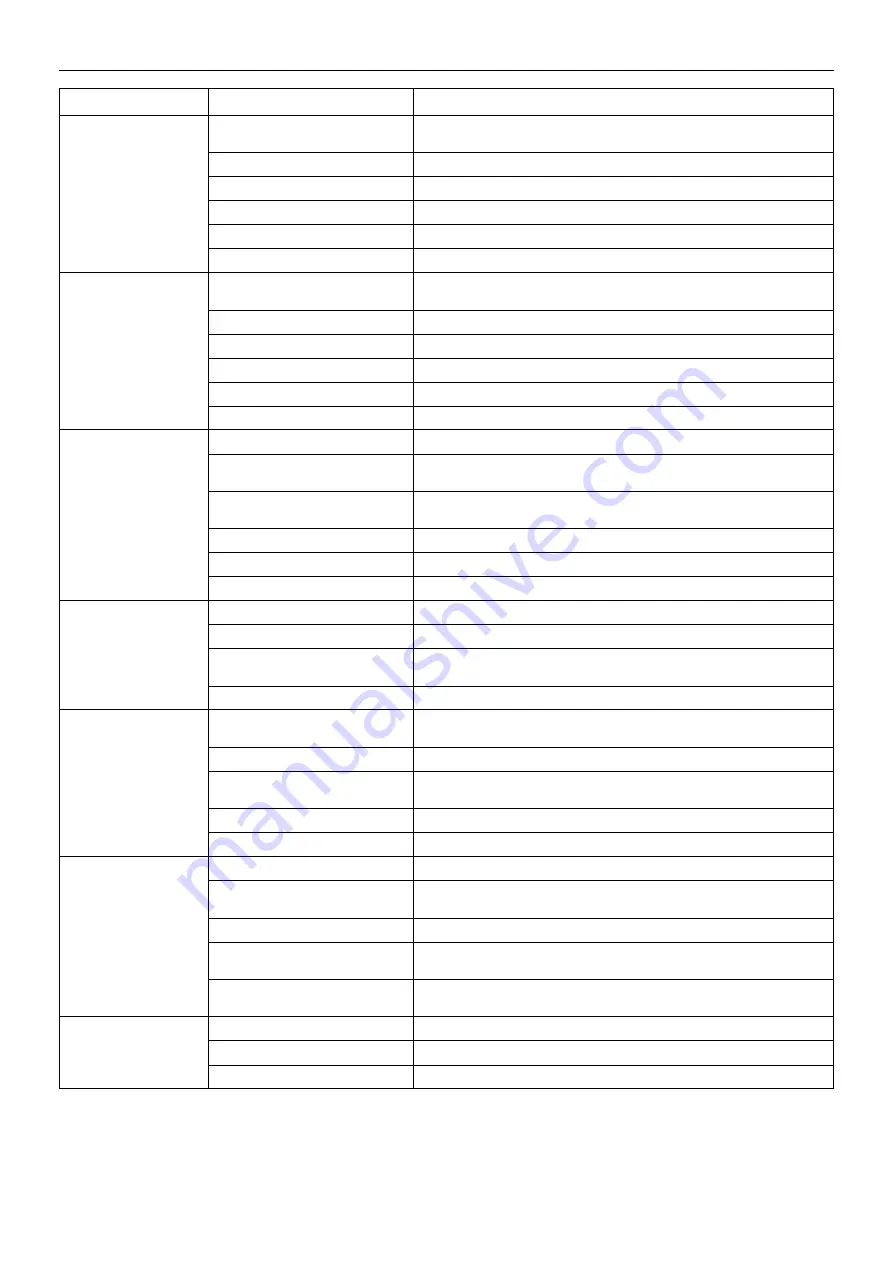

FAULT FINDING

91

7/124 - 10/104, 10/124 - 14/114, 14/84

FAULT

CAUSE

REMEDY

7. Low engine speed

Clogged fuel filters.

Service fuel filters. See Engine manual. Drain and clean fuel tanks. Add

clean fuel.

Operating pressure too high.

Reduce pressure to rated operating pressure.

Clogged air filter element(s).

Clean or replace air filter element(s).

Wrong air filter element(s).

Install correct air filter element(s).

Engine malfunctioning.

See troubleshooting in Engine manual.

Airend malfunctioning.

See Faults #11, #12.

8. Excessive vibration

Rubber mounting isolators loose or

damaged.

Tighten or replace.

Defective or imbalanced fan.

Replace fan.

Defective airend drive coupling.

Replace coupling.

Engine malfunctioning.

See troubleshooting in Engine manual.

Airend malfunctioning.

See Faults #7, #11, #12.

Engine idle speed too low.

See Fault #7. See Engine manual.

9. Low air delivery / low

cfm

Clogged air filter element(s).

Clean or replace air filter element(s).

Incorrect pressure regulation

adjustment.

Make adjustments per this manual.

Malfunctioning inlet unloader /

butterfly valve.

Inspect valve. Make adjustments per this manual.

Wrong air filter element(s).

Install correct air filter element(s).

Low engine speed.

See Fault #7. See Engine manual.

Compressed air leaks.

Locate and repair leaks.

10. Short air filter life

Dirty operating conditions.

Move compressor to cleaner environment.

Wrong air filter element(s).

Install correct air filter element(s).

Inadequate air filter element

cleaning.

Install new air filter element(s).

Incorrect stopping procedure.

Comply with procedure in this manual.

11. Compressor will

not unload

Malfunctioning inlet unloader /

butterfly valve.

Inspect valve. Make adjustments per this manual.

Malfunctioning pressure regulator.

Check pressure regulator. Check regulation lines for leaks.

Ice in regulation lines and/or

regulation orifice.

Apply heat to lines and/or orifice. Check operation of DC electric heaters, if

equipped.

Load solenoid leak or malfunction.

Replace load solenoid.

Plugged vent leak.

Clean and/or replace.

12. Safety valve opens

Operating pressure too high.

Reduce pressure to rated operating pressure.

Malfunctioning inlet unloader /

butterfly valve.

Inspect valve. Make adjustments per this manual.

Defective safety valve.

Replace safety valve.

Compressor will not unload fast

enough.

Check pressure regulator. Check regulation lines for leaks.

Ice in regulation lines and/or

regulation orifice.

Apply heat to lines and/or orifice. Check operation of DC electric heaters, if

equipped.

13. Excessive

carryover (compressor

oil in the compressed

air)

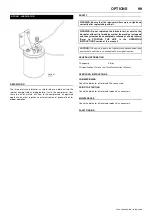

Blocked separator scavenge line.

Check scavenge line, drop tube, and orifice. Clean and replace as needed.

Deteriorated separator element.

Replace separator element.

Separator tank pressure too low.

Check the minimum pressure valve. Repair or replace as necessary.

Summary of Contents for 10/104

Page 2: ......

Page 4: ......

Page 11: ...ISO SYMBOLS 7 7 124 10 104 10 124 14 114 14 84 Replace any cracked protective shield ...

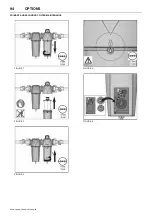

Page 83: ...MAINTENANCE 79 7 124 10 104 10 124 14 114 14 84 ...

Page 84: ...80 MAINTENANCE 7 124 10 104 10 124 14 114 14 84 ...

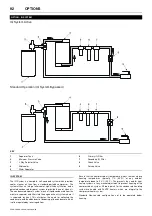

Page 92: ...88 MACHINE SYSTEMS 7 124 10 104 10 124 14 114 14 84 ...

Page 108: ......

Page 109: ......