MAINTENANCE

32

12/150_23136591

−

C en

CAUTION:

Start the machine (refer to PRIOR TO

STARTING and STARTING THE UNIT in the

OPERATING INSTRUCTIONS section of this manual)

and check for leakage before the machine is put back

into service.

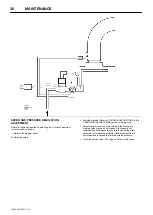

COMPRESSOR OIL COOLER AND ENGINE

RADIATOR

When grease, oil and dirt accumulate on the exterior surfaces of the

oil cooler and radiator, the efficiency is impaired. It is recommended

that each month the oil cooler and radiator be cleaned by directing a

jet of compressed air, (carrying if possible a non

−

flammable cleaning

solvent) over the exterior core of the cooler/radiator. This should

remove any accumulation of oil, grease and dirt from the exterior

core of the cooler so that the entire cooling area can radiate the heat

of the lubricating and cooling oil/water into the air stream.

WARNING: Hot engine coolant and steam can cause

injury. When adding coolant or antifreeze solution

to the engine radiator, stop the engine at least one

minute prior to releasing the radiator filler cap.

Using a cloth to protect the hand, slowly release the

filler cap, absorbing any released fluid with the

cloth. Do not remove the filler cap until all excess

fluid is released and the engine cooling system fully

depressurised.

WARNING: Follow the instructions provided by the

antifreeze supplier when adding or draining the

antifreeze solution. It is advisable to wear personal

protective equipment to prevent skin and eye

contact with the antifreeze solution.

AIR FILTER ELEMENTS

The air filter should be inspected regularly (refer to the

SERVICE/MAINTENANCE CHART

) and the element replaced when

the restriction indicator shows red or every 12 Months (1000 hours),

whichever comes first. The dust collector box(es) should be cleaned

daily (more frequently in dusty operating conditions) and not allowed

to become more than half full.

REMOVAL

CAUTION:

Never remove and replace element(s) when

the machine is running.

Clean the exterior of the filter housing and remove the filter element

by releasing the nut.

INSPECTION

Check for cracks, holes or any other damage to the element by

holding it up to a light source, or by passing a lamp inside.

Check the seal at the end of the element and replace if any sign of

damage is evident.

REASSEMBLY

Assemble the new element into the filter housing ensuring that the

seal seats properly.

Reset the restriction indicator by depressing the rubber diaphragm.

Assemble the dust collector box parts, ensuring that they are

correctly positioned.

Before restarting the machine, check that all clamps are tight.

VENTILATION

Always check that the air inlets and outlets are clear of debris etc.

CAUTION:

Never remove and replace element(s) when

the machine is running.

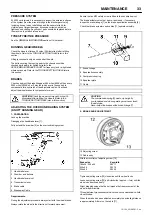

COOLING FAN DRIVE

Periodically check that the fan mounting bolts in the fan hub have

not loosened. If, for any reason, it becomes necessary to remove

the fan or re

−

tighten the fan mounting bolts, apply a good grade of

commercially available thread locking compound to the bolt threads

and tighten to the torque value shown in the

TORQUE SETTING

TABLE

later in this section.

The fan belt(s) should be checked regularly for wear and correct

tensioning.

FUEL SYSTEM

The fuel tank should be filled daily or every eight hours. To minimise

condensation in the fuel tank(s), it is advisable to top up after the

machine is shut down or at the end of each working day. At six

month intervals drain any sediment or condensate that may have

accumulated in the tank(s).

FUEL FILTER WATER SEPARATOR

The fuel filter water separator contains a filter element which should

be replaced at regular intervals (see the

SERVICE/MAINTENANCE

CHART

).

CHARGE AIR COOLER PIPEWORK

Inspect all hoses and clips on the charge cooler pipe work.

Engine damage will occur if the charge cooling system leaks.

HOSES

All components of the engine cooling air intake system should be

checked periodically to keep the engine at peak efficiency.

At the recommended intervals, (see the

SERVICE/MAINTENANCE

CHART

), inspect all of the intake lines to the air filter, and all flexible

hoses used for air lines, oil lines and fuel lines.

Periodically inspect all pipework for cracks, leaks, etc. and replace

immediately if damaged.

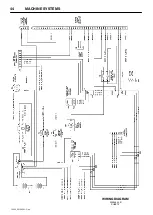

ELECTRICAL SYSTEM

WARNING: Always disconnect the battery cables

before performing any maintenance or service.

Inspect the safety shutdown system switches and the instrument

panel relay contacts for evidence of arcing and pitting. Clean where

necessary.

Check the mechanical action of the components.

Check the security of electrical terminals on the switches and relays

i.e. nuts or screws loose, which may cause local hot spot oxidation

.

Inspect the components and wiring for signs of overheating i.e.

discolouration, charring of cables, deformation of parts, acrid smells

and blistered paint.

BATTERY

Keep the battery terminals and cable clamps clean and lightly coated

with petroleum jelly to prevent corrosion.

The retaining clamp should be kept tight enough to prevent the

battery from moving.