65

PERIODICAL INSPECTION AND MAINTENANCE

.

12/150_23136625

−

C en

LUBRICATION & MAINTENANCE/DAILY

Daily Pre

−

starting Checks

Do the following BEFORE STARTING THE ENGINE for the first

time each day:

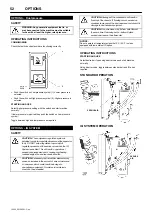

Check engine oil level on dipstick.

IMPORTANT: DO NOT add makeup oil until the oil level is

BELOW the crosshatch marks on the dipstick.

IMPORTANT: DO NOT fill above the top mark on the dipstick.

Oil levels anywhere within crosshatch are considered in the

acceptable range.

To change engine oil and oil filter:

Check the fuel filters for water or debris. If filter is fitted with a

see

−

through bowl, drain as needed based on a daily visual

inspection.

IMPORTANT: Drain water into a suitable container and dispose

of properly.

a) Loosen drain plugs (A) at bottom of fuel filters or bowls, if

equipped, two or three turns.

b) Loosen air bleed plug (B) two full turns on fuel filter mounting and

drain water from bottom until fuel starts to drain out.

c) When fuel starts to drain out, tighten drain plugs securely.

After draining water from the fuel filters, the filters must be primed by

bleeding all air from the fuel system.

Changing Engine Oil and Replacing Filter

Your engine is equipped with a special oil filter.

The oil and filter change interval is 500 hours or every 6 months,

whichever comes first.

NOTE: If diesel fuel with a sulfur content greater than 0.05% (500

ppm) is used, the oil and filter change interval is reduced.

To change engine oil and oil filter:

1. Run engine approximately 5 minutes to warm up oil. Shut engine

off.

2. Remove engine oil drain plug.

3. Drain crankcase oil from engine while warm.

4. Turn filter element using a suitable filter wrench to remove.

Discard oil filter element.

IMPORTANT: Filtration of oils is critical to proper lubrication.

Always change filter regularly.

5. Apply clean engine oil to the new filter at the inner and outer

seals and to filter threads.

6. Wipe both sealing surfaces of the filter head with a clean rag.

Ensure dust seal is in place, replace if damaged.

IMPORTANT: When installing filter element, HAND TIGHTEN

only. A filter wrench may be used for REMOVAL ONLY.

7. Install and tighten oil filter by hand until firmly against dust seal.

DO NOT apply an extra 3/4 to 1

−

1/4 turn after gasket contact as

done with standard filters.

8. Tighten drain plug to specifications.

Specification

Oil Pan Drain Plug With Copper Washer—

Torque 70 N

•

m (52 lb ft)

Oil Pan Drain Plug With O

−

Ring—

Torque 50 N

•

m (37 lb ft)

9. Fill engine crankcase with PRO

−

TEC Engine Fluid.

To determine the correct oil fill quantity for your engine, see ENGINE

CRANKCASE OIL FILL QUANTITIES in the Specifications Section

of this manual.

IMPORTANT: Immediately after completing any oil change,

crank engine for 30 seconds without permitting engine to start.

This will help insure adequate lubrication to engine

components before engine starts.

NOTE: Crankcase oil capacity may vary slightly. ALWAYS fill

crankcase within crosshatch marks on dipstick. DO NOT overfill.

10. Start engine and run to check for possible leaks.

11. Stop engine and check oil level after 10 minutes. Oil level

reading should be within crosshatch of dipstick.

Cleaning Crankcase Vent Tube

If you operate the engine in dusty conditions, clean the tube at

shorter intervals.

1. Remove and clean crankcase vent tube.

2. Install the vent tube. Be sure the O

−

ring fits correctly in the

rocker arm cover for elbow adapter.

Replacing Fuel Filter Elements

Engine is equipped with a primary fuel filter (or pre

−

filter) with water

bowl and a final filter. Both filters are replaced at the same 500

−

hour

interval.

CAUTION: Escaping fluid under pressure can

penetrate the skin causing serious injury. Relieve

pressure before disconnecting fuel or other lines.

Tighten all connections before applying pressure.

Keep hands and body away from pinholes and

nozzles which eject fluids under high pressure. Use

a piece of cardboard or paper to search for leaks.

Do not use your hand.

1. Close fuel shut

−

off valve, if equipped.

2. Thoroughly clean fuel filter assemblies and surrounding areas.

3. Disconnect water sensor wiring (if equipped).

4. Loosen drain plugs and drain fuel into a suitable container.

5. Inspect filter mounting base for cleanliness. Clean as required.

6. Install new filter elements onto mounting bases.

If equipped with water separator bowl (E), remove filter element from

separator bowl. Drain and clean separator bowl. Dry with

compressed air. Install bowl onto new element. Tighten securely.

7. Install and tighten filter by hand. DO NOT fill the new filter with

fuel prior to installing.

8 Reconnect water sensor wiring (if equipped).

9 Open fuel shut

−

off valve and bleed the fuel system.

Checking Belt Tensioner Spring Tension and Belt Wear

(Automatic Tensioner)

Belt drive systems equipped with automatic (spring) belt tensioners

cannot be adjusted or repaired. The automatic belt tensioner is

designed to maintain proper belt tension over the life of the belt. If

tensioner spring tension is not within specification, replace tensioner

assembly.

Checking Belt Wear

The belt tensioner is designed to operate within the limit of arm

movement provided by the cast stops when correct belt length and

geometry is used.

Visually inspect cast stops on belt tensioner assembly.

If the tensioner stop on swing arm is hitting the fixed stop, check

mounting brackets (alternator, belt tensioner, idler pulley, etc.) and

the belt length. Replace belt as needed