70

FUEL, LUBRICANTS AND COOLANT

9/275, 9/305, 12/250, 17/240, 21/220

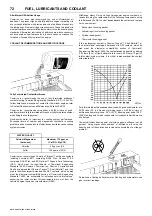

FUEL RECOMMENDATIONS AND SPECIFICATIONS

Fuel Recommendations - Industrial Applications

Listed below are the general specifications for the engines covered in

this manual:

Cummins Inc. recommends the use of ASTM number 2D fuel. The use

of number 2D diesel fuel will result in optimum engine performance.

The engine has been optimised for use with an exhaust aftertreatment

to meet the Tier 4 interim/Stage IIIB off-highway emissions regulations.

It

must

operate on ultra-low sulfur diesel (ULSD) with a maximum

sulfur content of 15 ppm in the United States and 10 ppm in the

European Union. Failure to do so can permanently damage engine and

aftertreatment systems within a short period of time. This damage

could cause the engine to become inoperable and affect the warranty

coverage on the engine.

Ultra-low sulfur diesel fuel, for Europe should not exceed 0.0010 (10

ppm) mass percent sulfur content. There is no acceptable substitute.

At operating temperatures below 0°C (32°F), acceptable performance

can be obtained by using blends of number 2D and number 1D.

The following chart lists acceptable types of fuels for this engine.

1. Any adjustment to compensate for reduced performance with a fuel

system using alternate fuel is

not

warrantable.

2. Winter blend fuels, such as those found at commercial fuel

dispensing outlets, are combinations of number 1D and number 2D

diesel fuel, and are acceptable.

3. BTU Content/Degree API Gravity - Low API gravity fuels have a

higher thermal energy content (BTU). As a general rule, there is a

3 to 5 percent decrease in BTU content for every 10 degree

increase in API gravity; there is also a 0.7 degree API gravity

increase with an increase in fuel temperature. This decrease in

energy content equates roughly to the same percentage of power

loss. Use of fuels with higher API gravity will cause higher than

normal fuel consumption.

The equipment OEM is required to display readily visible labels on the

dashboard (or instrument panel) and near all fuel fill inlets that state

"Use Ultra Low-Sulfur Diesel Fuel Only" or "Ultra Low-Sulfur Diesel

Fuel Only"

ULSD/Biodiesel blends up to B20 (20 percent biodiesel) supplied by a

BQ9000 certified supplier are acceptable.

For information on alternative fuels, such as biodiesel, and additional

information for fuel recommendations and specifications, reference the

Fuels for Cummins® Engines, Bulletin 3379001.

LUBRICATING OIL RECOMMENDATIONS AND SPECIFICATIONS

General Information - QSL Engines

Listed below are the general specifications for the engines covered in

this manual:

The use of quality engine lubricating oils, combined with appropriate oil

drain and filter change intervals, is a critical factor in maintaining

engine performance and durability.

Cummins Inc. requires the use of a high-quality SAE 15W-40 heavy-

duty engine oil, such as CJ-4 or Euro ACEA E9.

A sulphated ash limit of 1.0 mass percent is suggested for optimum

piston deposit, diesel particulate filter life, and oil consumption control.

Special "break-in" oils are not recommended for use in new or rebuilt

Cummins® engines. Use the same lubricating oil that will be used in

normal engine operations.

Use of "synthetic engine oils" (those made with API group 3 or group 4

base stocks) is permitted, subject to the same performance and

viscosity limitations of petroleum (mineral) based engine oils. The

same oil change intervals

must

be applied to synthetic oils that are

applied to petroleum (mineral) based engine oils.

For further details and discussion of engine lubricating oils for

Cummins® engines, refer to the latest revision of Cummins® Engine

Oil Recommendations, Bulletin 3810340.

WARNING: Do not mix petrol, alcohol, or gasohol with diesel

fuel. This mixture can cause an explosion.

CAUTION: Due to the precise tolerances of diesel injection systems,

it is extremely important that the fuel be kept clean and free of dirt or

water. Dirt or water in the system can cause severe damage to both

the fuel pump and the fuel injectors.

CAUTION: Lighter fuels can reduce fuel economy or possibly dam-

age fuel system components.

CAUTION: Do not use diesel fuel blended with lubricating oil in

engines equipped with an aftertreatment system. Service intervals

for aftertreatment systems will be reduced.

CAUTION: Ultra-low sulfur diesel fuel is required for correct opera-

tion of the aftertreatment system. If ultra-low sulfur diesel fuel is not

used, the engine could possibly not meet emission regulations and

the aftertreatment system could possibly be damaged.

ACCEPTABLE TYPES OF FUEL

Number

1D Diesel

(1) (2)

Number

2D Diesel

(2)

Number

1K

Kerosene

Jet-A

Jet-A1

JP-5

JP-8

Jet-B

JP-4

CITE

OK

OK

NOT OK

NOT OK

NOT OK

NOT OK

NOT OK

NOT OK

NOT OK

NOT OK

48-34(3)

40-24(3)

50-35(3)

51-37(3)

51-37(3)

48-36(3)

51-37(3)

57-45(3)

57-45(3)

57-45(3)

NOTE:

Cummins Inc. recommends that the cetane number of diesel

fuel be a minimum of 45 for engines that are expected to operate at

temperatures below 0°C (32°F) and a minimum of 42 for engines

that are operated at temperatures above 0°C (32°F).

NOTE:

The use of diesel fuel with a lower than recommended cet-

ane number can cause hard starting, instability, and excessive white

smoke. To maintain satisfactory operation at low ambient tempera-

tures, it is important to specify diesel fuel of the correct cetane num-

ber.

NOTE:

Cummins Inc. requires all permissible fuels to have ade-

quate fuel lubricity. This means the BOCLE number is 3100 or

greater as measured by ASTM specification D6078, Scuffing Load

Ball On Cylinder Evaluator (SLBOCLE). Lubricity can also be mea-

sured by ASTM, specification D6079, ISO 12156, High Frequency

Reciprocating Rig (HFRR), in which the fuel

must

have a wear scar

diameter of 0.45 mm (0.02 in) or less.