80

PERIODICAL INSPECTION AND MAINTENANCE

9/275, 9/305, 12/250, 17/240, 21/220

FUEL SYSTEM

The fuel injection pump and injector nozzles are precisely

manufactured, and therefore, using fuel which contains water or dust

particles will result in either injection pump plunger seizure or injector

nozzle seizure. A fuel filter element blocked with sludge or dust

particles will lead to reduced engine output.

Perform inspection and maintenance periodically as follows:

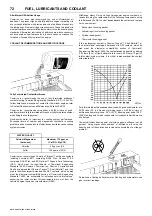

Fig. 15

A

Filter element

B

Drain valve

Draining Water from Fuel Filter/separator.

The fuel filter/separator is provided to allow water to be drained from

the fuel system. Water is heavier than fuel so any water contained in

the system will collect in the bottom of the bowl.

Place a suitable container under the separator to prevent any spillage

inside the machine.

Slacken the drain valve 'B' until water drains from the vent tube.

When all the water has been evacuated, tighten the drain valve 'B'.

Fuel filter/separator element change.

The fuel filter/separator also provides primary filtration and the element

'A' should be changed every 500 operating hours or 6 months,

whichever comes first.

Change procedure:

Disconnect fuel sensor (where fitted). Loosen drain plug B and empty

fuel into suitable container

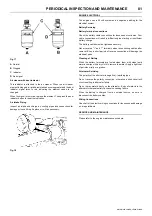

Fig. 16

Unscrew the element 'A' from the head taking care not to spill fuel

inside the machine. Remove fuel sensor (where fitted) and re-fit to new

filter element.

Discard the old element into a suitable container.

Using a clean cloth, wipe the sealing face of the filter/separator head

to ensure correct seating of the sealing ring.

Fill the element/bowl assembly with clean fuel oil then apply a light coat

of clean engine oil to the new element seal ring.

Screw the new element onto the head firmly by hand.

The engine has a self priming system that purges air from the fuel

system.

AIR INTAKE SYSTEM

The air filter should be inspected regularly (refer to the SERVICE/

MAINTENANCE CHART) and the element replaced when the

restriction indicator lamp illuminates. The dust collector box(es) should

be cleaned daily (more frequently in dusty operating conditions) and

not allowed to become more than half full.

The safety element should be renewed every 2000 hours or every

other main filter element change, whichever comes first.

Removal

Clean the exterior of the filter housing and remove the filter element by

releasing the nut.

If the safety element is to be renewed, thoroughly clean the interior of

the filter housing prior to removing the safety element.

Inspection

Check for cracks, holes or any other damage to the element by holding

it up to a light source, or by passing a lamp inside.

Check the seal at the end of the element and replace if any sign of

damage is evident.

Reassembly

Assemble the new element into the filter housing ensuring that the seal

seats properly.

Secure the element in the housing by hand tightening the nut.

Assemble the dust collector box parts, ensuring that they are correctly

positioned.

Before restarting the machine, check that all clamps are tight.

Air cleaner

Engine performance and life vary with the air intake conditions.

A dirty air cleaner element reduces the amount of intake air, causing

reduced engine output and possible engine damage.

Also, a damaged element leads to abrasion of cylinders and valves,

resulting in increased oil consumption, reduced output and shortened

engine life.

The filter element should be changed at 1000 hours or 12 months,

whichever comes first, or sooner if the restriction indicator shows red.

See below.

NOTE:

The cartridge and bowl contain fuel. Take care not to spill it

during disassembly and reassembly.

CAUTION: Never remove and replace element(s) when the machine

is running.

CAUTION: If inspection reveals damage to the main element, the

safety element must be replaced.

CAUTION: Safety elements must not be cleaned or re-used.