PERIODICAL INSPECTION AND MAINTENANCE

81

9/275, 9/305, 12/250, 17/240, 21/220

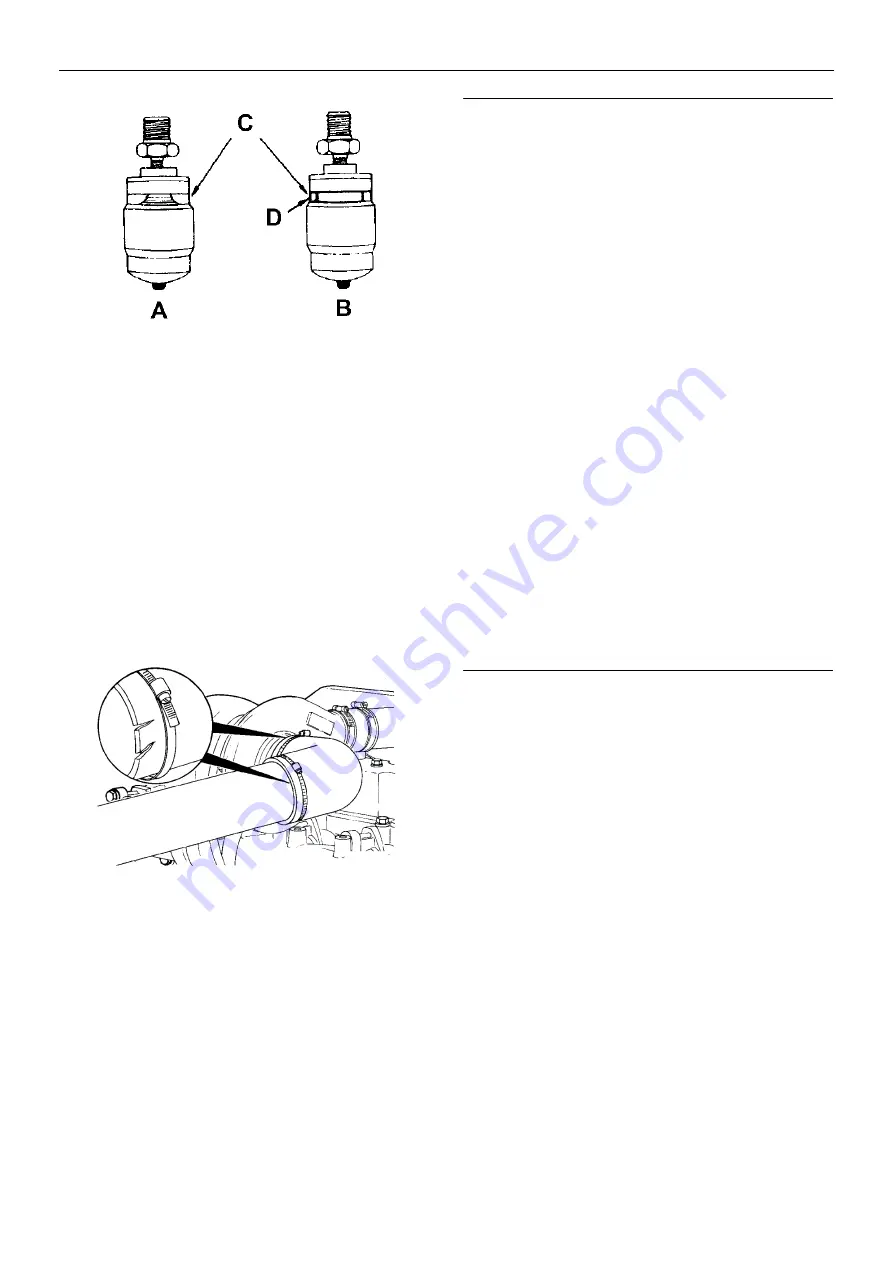

Fig. 17

A

Normal

B

Clogged

C

Indicator

D

Red signal

Air cleaner with dust indicator

This indicator is attached to the air cleaner. When the air cleaner

element is clogged, air intake resistance becomes greater and the dust

indicator signal turns to red indicating the element needs to be

changed.

When the signal turns to red, replace the element. Then press the dust

indicator button to reset the indication.

Air Intake Piping

Inspect air intake and charge air cooling pipes and connections for

damage or loose fitting. Replace or re-fit as necessary.

Fig. 18

ENGINE ELECTRICAL

The engine uses a 24 volt system and a negative earthing for the

electrical system.

Battery Servicing

Battery terminal connections

Check the battery cable connections for looseness or corrosion. Poor

cable connections will result in difficult engine starting or insufficient

battery charge.

The battery cables must be tightened securely.

Never reverse "+" and "-" terminals when reconnecting cables after

removal. Even a short period of reverse connection will damage the

electrical parts.

Cleaning of Battery

When the battery terminals are fouled clean them with clean tepid

water and wipe with a dry cloth to remove the water. Apply a light coat

of petroleum jelly or a grease.

Alternator Servicing

The polarity of the alternator is negative (-) earthing type.

Do not reverse the polarity connection, otherwise a short circuit will

occur resulting in alternator failure.

Do not spray water directly on the alternator. Entry of water into the

alternator creates electrolytic corrosion causing failure.

When the battery is charged from an external source, be sure to

disconnect the battery cables.

Wiring Connections

Check all of the electric wiring connections for looseness and damage

on a regular basis.

SERVICE AND MAINTENANCE

Please refer to the engine maintenance schedule.