10

NOISE EMISSION

7/20, P65

INTRODUCTION

The unit for which this Maintenance Log is provided conforms to U.S. E.P.A. Regulations for Noise Emissions, applicable to Portable Air

Compressors.

The purpose of this book is to provide (1) the Maintenance Performance Schedule below for all required noise emission controls and (2) space so

that the purchaser or owner can record what maintenance was done, by whom, where and when. Detailed instructions on the maintenance items

below are given on the following page.

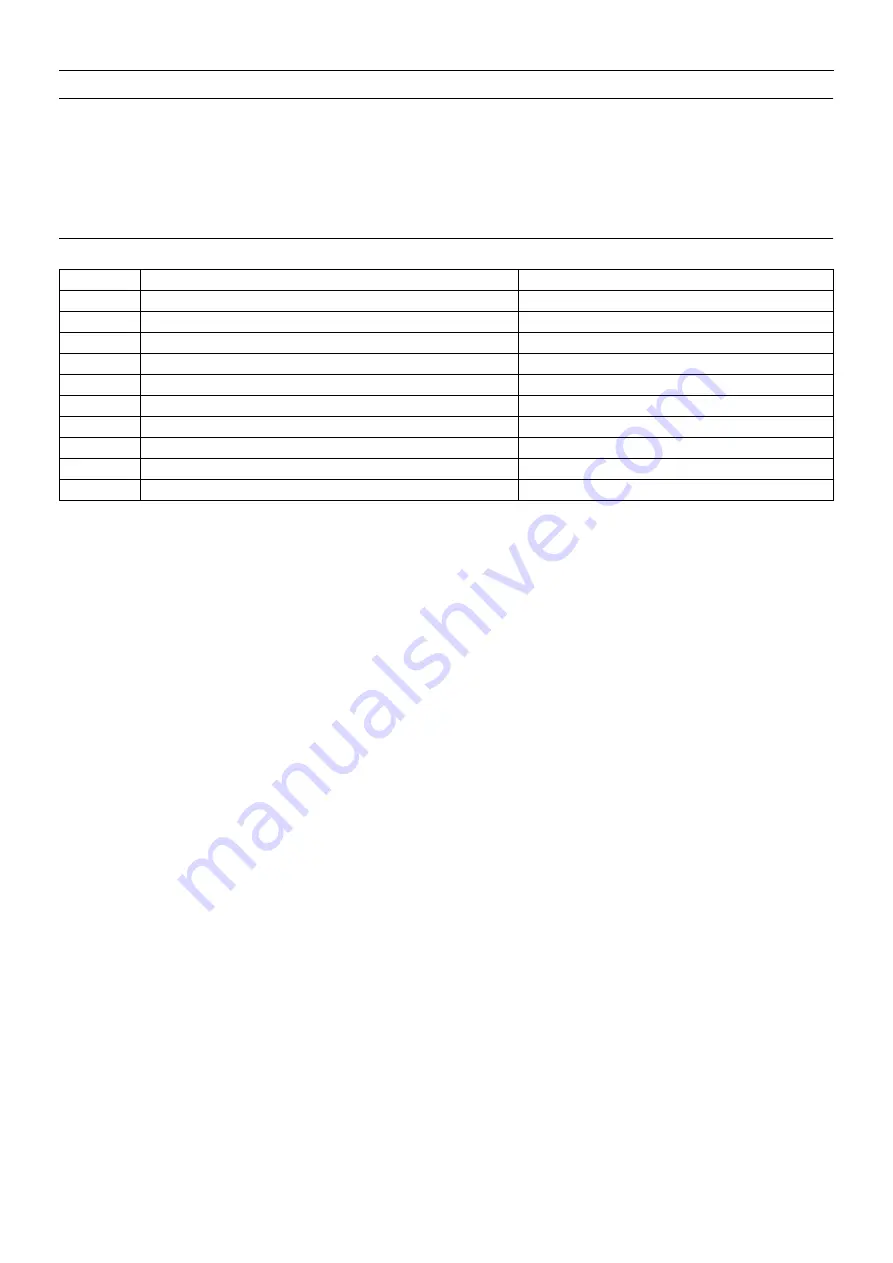

MAINTENANCE SCHEDULE

ITEM

AREA

PERIOD

A.

COMPRESSED AIR LEAKS

AS DETECTED

B.

SAFETY AND CONTROL SYSTEMS

AS DETECTED

C.

ACOUSTIC MATERIALS

DAILY

D.

FASTENERS

100 HOURS

E.

ENCLOSURE PANELS

100 HOURS

F.

AIR INTAKE & ENGINE EXHAUST

100 HOURS

G.

COOLING SYSTEMS

250 HOURS

H.

ISOLATION MOUNTS

250 HOURS

I.

ENGINE OPERATION

SEE OPERATOR’S MANUAL

J.

FUELS & LUBRICANTS

SEE OPERATOR’S MANUAL

Summary of Contents for 7/20

Page 9: ...DECALS 7 7 20 P65 Engine oil drain Cold Start Procedure...

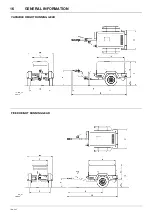

Page 18: ...16 GENERAL INFORMATION 7 20 P65 VARIABLE HEIGHT RUNNING GEAR FIXED HEIGHT RUNNING GEAR...

Page 50: ......

Page 51: ......

Page 52: ......