MAINTENANCE

27

7/20, P65

ROUTINE MAINTENANCE

This section refers to the various components which require periodic

maintenance and replacement.

The

MAINTENANCE SHEDULE

indicates the various components’

descriptions and the intervals when maintenance has to take place. Oil

capacities, etc., can be found in the

GENERAL INFORMATION

section

of this manual.

For any specification or specific requirement on service or preventative

maintenance for the engine, refer to the

Engine Manufacturer’s

Manual

.

Compressed air can be dangerous if incorrectly handled. Before doing

any work on the unit, ensure that all pressure is vented from the system

and that the machine cannot be started accidentally.

If the automatic blowdown fails to operate, then pressure must be

gradually relieved by operating the manual blowdown valve. Suitable

personal protective equipment should be worn.

Ensure that maintenance personnel are adequately trained, competent

and have read the Maintenance Manuals.

Prior to attempting any maintenance work, ensure that:-

•

all air pressure is fully discharged and isolated from the system. If

the automatic blowdown valve is used for this purpose, then allow

enough time for it to complete the operation.

•

the discharge pipe / manifold area is depressurised by opening the

discharge valve, whilst keeping clear of any airflow from it.

•

the machine cannot be started accidentally or otherwise, by posting

warning signs and/or fitting appropriate anti-start devices.

•

all residual electrical power sources (mains and battery) are

isolated.

Prior to opening or removing panels or covers to work inside a

machine, ensure that:-

•

anyone entering the machine is aware of the reduced level of

protection and the additional hazards, including hot surfaces and

intermittently moving parts.

•

the machine cannot be started accidentally or otherwise, by posting

warning signs and/or fitting appropriate anti-start devices.

Prior to attempting any maintenance work on a running machine,

ensure that:-

•

the work carried out is limited to only those tasks which require the

machine to run.

•

the work carried out with safety protection devices disabled or

removed is limited to only those tasks which require the machine to

be running with safety protection devices disabled or removed.

•

all hazards present are known (e.g. pressurised components,

electrically live components, removed panels, covers and guards,

extreme temperatures, inflow and outflow of air, intermittently

moving parts, safety valve discharge etc.).

•

appropriate personal protective equipment is worn.

•

loose clothing, jewelry, long hair etc. is made safe.

•

warning signs indicating that Maintenance Work is in Progress are

posted in a position that can be clearly seen.

Upon completion of maintenance tasks and prior to returning the

machine into service, ensure that:-

•

the machine is suitably tested.

•

all guards and safety protection devices are refitted.

•

all panels are replaced, canopy and doors closed.

•

hazardous materials are effectively contained and disposed of.

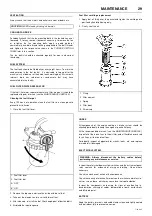

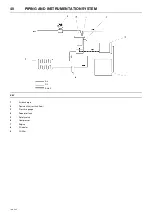

PROTECTIVE SHUTDOWN SYSTEM

Comprises:

•

Low engine oil pressure switch

•

High discharge air temperature switch

•

High engine coolant temperature switch

Low engine oil pressure switch.

At three month intervals, test the engine oil pressure switch circuit as

follows:

•

Start the machine.

•

Remove a wire from one terminal of the switch. The machine should

shutdown.

At twelve month intervals, test the engine oil pressure switch as

follows:-

•

Remove the switch from the machine.

•

Connect it to an independent low pressure supply (either air or oil).

•

The switch should operate at 0,83 bar (12 psi).

•

Refit the switch.

Temperature switch(es).

At three month intervals, test the temperature switch circuit(s) as

follows:

•

Start the machine.

•

Disconnect each switch in turn. The machine should shutdown.

•

Re-connect the switch.

High discharge air temperature switch(es).

At twelve month intervals, test the air discharge temperature switch(es)

by removing it from the machine and immersing in a bath of heated oil.

The switch should operate at 120°C (248°F.) Refit the switch.

High coolant temperature switch.

At twelve month intervals, test the coolant temperature switch by

removing it from the machine and immersing in a bath of heated oil.

The switch should operate at 115°C (239°F). Refit the switch.

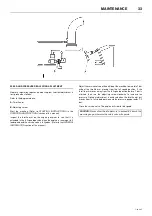

SCAVENGE LINE

The scavenge line runs from the combined orifice/drop tube in the

separator tank, to the orifice fitting located in the airend.

Examine the orifice, check valve and hoses at every service or in the

event of oil carryover into the discharge air.

It is good preventative maintenance to check that the scavenge line

and tube are clear of any obstruction each time the compressor

lubricant is changed as any blockage will result in oil carryover into the

discharge air.

NOTE:

Do not press the load button.

CAUTION:

Never remove or replace switches when the machine is

running.

Summary of Contents for 7/20

Page 9: ...DECALS 7 7 20 P65 Engine oil drain Cold Start Procedure...

Page 18: ...16 GENERAL INFORMATION 7 20 P65 VARIABLE HEIGHT RUNNING GEAR FIXED HEIGHT RUNNING GEAR...

Page 50: ......

Page 51: ......

Page 52: ......