28

MAINTENANCE

7/20, P65

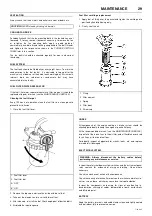

COMPRESSOR OIL FILTER

Refer to the

MAINTENANCE SHEDULE

in this section for the

recommended servicing intervals.

Removal

Clean the exterior of the filter housing and remove the spin-on element

by turning it in a counter-clockwise direction.

Inspection

Examine the filter element.

Reassembly

Clean the filter gasket contact area and install the new element by

screwing in a clockwise direction until the gasket makes contact with

the filter housing. Tighten a further

1

/

2

to

3

/

4

of a revolution.

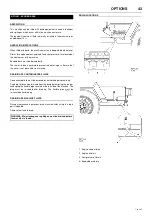

COMPRESSOR OIL SEPARATOR ELEMENT

Normally the separator element will not require periodic maintenance

provided that the air and oil filter elements are correctly maintained.

If, however, the element has to be replaced, then proceed as follows:

Removal

Disconnect all hoses and tubes from the separator tank cover plate.

Remove the drop-tube from the separator tank cover plate and then

remove the cover plate. Remove the separator element.

Inspection

Examine the filter element. Examine all hoses and tubes, and replace

if necessary.

Reassembly

Thoroughly clean the orifice/drop tube and filter gasket contact area

before reassembly. Install the new element.

Reposition the cover plate, taking care not to damage the gasket, and

replace the cover plate screws tightening in a criss-cross pattern to the

recommended torque (refer to the

TORQUE SETTING TABLE

later in

this section).

Engage the adaptor in the cover plate with the drop-tube integral with

the filter, reconnect all hoses and tubes to the separator tank cover

plate.

Replace the compressor oil (refer to

LUBRICATION

later in this

section).

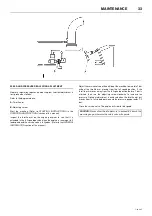

COMPRESSOR OIL COOLER AND ENGINE RADIATOR

When grease, oil and dirt accumulate on the exterior surfaces of the oil

cooler and radiator, the efficiency is impaired. It is recommended that

each month the oil cooler and radiator be cleaned by directing a jet of

compressed air, (carrying if possible a non-flammable cleaning

solvent) over the exterior core of the cooler/radiator. This should

remove any accumulation of oil, grease and dirt from the exterior core

of the cooler so that the entire cooling area can radiate the heat of the

lubricating and cooling oil/coolant into the air stream.

AIR FILTER ELEMENTS

The air filter should be inspected regularly (refer to the

MAINTENANCE SHEDULE

) and the element replaced when the

restriction indicator shows red or every 6 Months (500 hours),

whichever comes first. The dust collector box(es) should be cleaned

daily (more frequently in dusty operating conditions) and not allowed to

become more than half full.

Removal

Clean the exterior of the filter housing and remove the filter element by

releasing the nut.

Inspection

Check for cracks, holes or any other damage to the element by holding

it up to a light source, or by passing a lamp inside.

Check the seal at the end of the element and replace if any sign of

damage is evident.

Reassembly

Assemble the new element into the filter housing ensuring that the seal

seats properly.

Reset the restriction indicator by depressing the rubber diaphragm.

Assemble the dust collector box parts, ensuring that they are correctly

positioned.

Before restarting the machine, check that all clamps are tight.

WARNING: Do not remove the filter(s) without first making sure

that the machine is stopped and the system has been

completely relieved of all air pressure. (Refer to

STOPPING THE

UNIT

in the

OPERATING INSTRUCTIONS

section of this

manual).

CAUTION:

If there is any indication of the formation of varnishes,

shellacs or lacquers on the filter element, it is a warning that the

compressor lubricating and cooling oil has deteriorated and that it

should be changed immediately. Refer to LUBRICATION later in this

section.

CAUTION:

Start the machine (refer to PRIOR TO STARTING and

STARTING THE UNIT in the OPERATING INSTRUCTIONS section

of this manual) and check for leakage before the machine is put back

into service.

WARNING: Do not remove the filter(s) without first making sure

that the machine is stopped and the system has been

completely relieved of all air pressure. (Refer to

STOPPING THE

UNIT

in the

OPERATING INSTRUCTIONS

section of this

manual).

WARNING: Do not remove the staple from the anti-static gasket

on the separator element since it serves to ground any possible

static build-up. Do not use gasket sealant since this will affect

electrical conductance.

CAUTION:

Start the machine (refer to PRIOR TO STARTING and

STARTING THE UNIT in the OPERATING INSTRUCTIONS section

of this manual) and check for leakage before the machine is put back

into service.

WARNING: Hot engine coolant and steam can cause injury.

When adding coolant or antifreeze solution to the engine

radiator, stop the engine at least one minute prior to releasing

the radiator filler cap. Using a cloth to protect the hand, slowly

release the filler cap, absorbing any released fluid with the cloth.

Do not remove the filler cap until all excess fluid is released and

the engine cooling system fully depressurised.

WARNING: Follow the instructions provided by the antifreeze

supplier when adding or draining the antifreeze solution. It is

advisable to wear personal protective equipment to prevent skin

and eye contact with the antifreeze solution.

CAUTION:

Never remove and replace element(s) when the machine

is running.

Summary of Contents for 7/20

Page 9: ...DECALS 7 7 20 P65 Engine oil drain Cold Start Procedure...

Page 18: ...16 GENERAL INFORMATION 7 20 P65 VARIABLE HEIGHT RUNNING GEAR FIXED HEIGHT RUNNING GEAR...

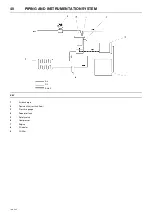

Page 50: ......

Page 51: ......

Page 52: ......