MAINTENANCE

19

7/53

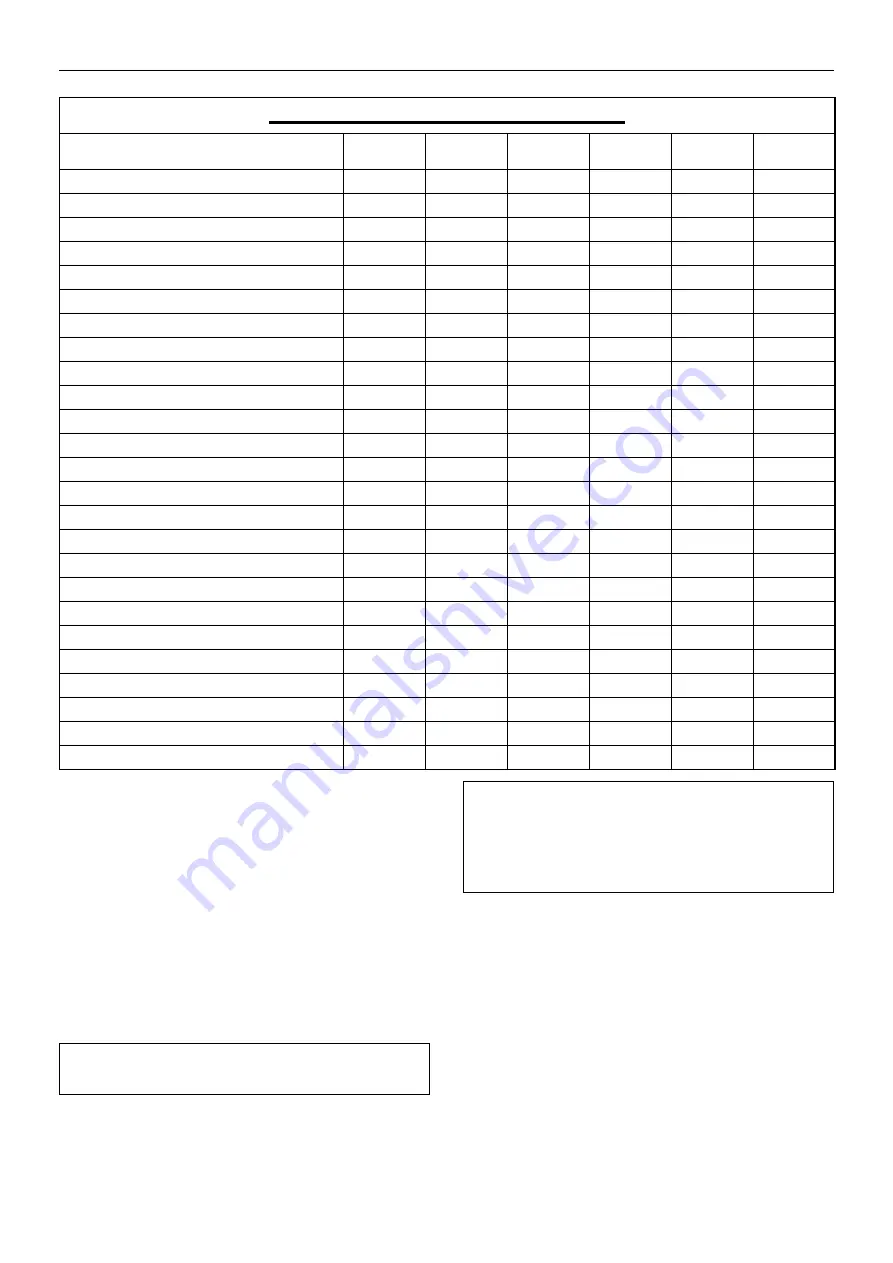

MAINTENANCE SCHEDULE

Daily

Weekly

Monthly

6 Monthly.

500 hrs

1 year.

1000 hrs

2000 hrs

Compressor Oil Level

C

Engine Oil Level

C

Coolant Level

C

Gauges/Lamps

C

Air cleaner service indicators

C

Fuel Tank

C

Fuel/Water separator

D

Fluid Leaks

C

Radiator Filler Cap

C

Crankcase Breather Tube

C

Air Cleaner Dust Ejector Valve

C

Fan / Alternator / Generator Belts

C

Battery connections/Electrolyte

C

Tire Pressure & Surface

C

Wheel Lug Nuts

C

Hoses ( Oil,Air,Intake...)

C

Automatic Shutdown System

C

Air Cleaner System

C

Coolers & Radiator Exterior

C

Fastener & Guards

C

Primary Air Cleaner Elements

R/WI

Secondary Air Cleaner Elements

R/WI

Fuel/Waterseparator element

R

Final Fuel Filter

R

Engine Oil Filter

R

C

=

Check and act if required

T

=

Test

D

=

Drain

R

= Replace

R/WI

= Replace or when indicated earlier

C/R

= Check and replace if required

G/C

= Grease and check

C/A

= Check and adjust if required

Refer to specific sections of the operator’s manual for more

information.

NOTE:

500 and 1000 hour intervals are meant to be repeated at

every 500 or 1000 hours. Other intervals only to be performed at

hours indicated.

NOTE:

All fluid and filter intervals are valid for near perfect conditions

only. High ambient temperatures - high dust concentration - high

humidity as well as using lower grade oils and fuels will require a

decrease in maintenance intervals.

Contact your Doosan Infracore Portable Power dealer for more

information or assistance in determining the optimum intervals for

your application.

Summary of Contents for 7/53

Page 2: ......

Page 4: ......

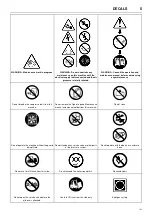

Page 11: ...DECALS 7 7 53 Engine oil drain...

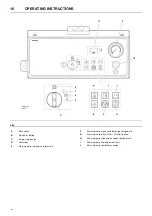

Page 15: ...GENERAL INFORMATION 11 7 53 7 53 FIXED HEIGHT RUNNING GEAR 7 53 VARIABLE HEIGHT RUNNING GEAR...

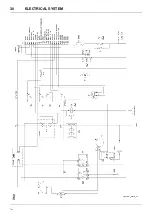

Page 34: ...30 ELECTRICAL SYSTEM 7 53 7 53...

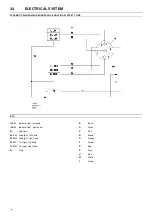

Page 36: ...32 ELECTRICAL SYSTEM 7 53 7 53...

Page 44: ...40 OPTIONS 7 53 WATER SEPARATOR MAINTENANCE FIGURE 4 FIGURE 5 FIGURE 1 FIGURE 2 FIGURE 3...

Page 58: ......

Page 59: ......

Page 60: ......