26

MAINTENANCE

7/53

Completely drain the receiver/separator system including the piping

and oil cooler by removing the drain plug(s) and collecting the used oil

in a suitable container.

Replace the drain plug(s) ensuring that each one is secure.

COMPRESSOR OIL FILTER ELEMENT

Refer to the

SERVICE / MAINTENANCE CHART

in this section for

service intervals.

LONG TERM STORAGE RECOMMENDATIONS

(6 months or more)

Spare Airends

•

Long--term storage of airends should include filling the airend with

the standard compressor fluid, PRO--TEC, XHP605 or XHP405.

Upon installation of the airend, drain the storage oil from the airend

and proceedwith the installation, assuring fresh oil is poured into the

intake prior to start up.

Portable Compressors

•

Airend -- Remove the intake connection and pour the airend intake

full with Doosan compressor fluid PRO--TEC, XHP605 or XHP405.

Reconnect the intake connection.

•

Engine cooling system -- Treat with rust inhibitor and drain. Check

with engine dealer for further recommendations.

•

Compressor Oil Filter/s-- fill with Doosan compressor fluid PRO--

TEC, XHP605 or XHP405.

•

Seal all opening with waterproof tape.

•

Place a desiccant in the exhaust pipes, engine and compressor air

intake pipes.

•

Loosen tension on belts, fan, airend, etc.

•

Block axles so tyres are off ground and do not support any weight.

•

Disconnect battery cables.

•

Drain fuel system.

SHORT TERM STORAGE

Machines that stand idle for extended periods of timegreater than

30 days:

•

Start and operate the machine every 30 days. Operate long enough

to allow the engine and compressor to reach operating

temperature.

•

Open and close the service valve to exercise machine fromfull load

to idle RPM.

•

Drain fuel tank to remove any water.

•

Drain water from fuel water separator.

NOTE:

If the machine has been operating under adverse conditions,

or has suffered long shutdown periods, then more frequent service

intervals will be required.

WARNING:

DO NOT

, under any circumstances, remove any

drain plugs or the oil filler plug from the compressor lubricating

and cooling system without first making sure that the machine

is stopped and the system has been completely relieved of all air

pressure (refer to

STOPPING THE UNIT

in the

OPERATING IN-

STRUCTIONS

section of this manual).

NOTE:

If the oil is drained immediately after the machine has been

running, then most of the sediment will be in suspension and will

therefore drain more readily.

CAUTION:

Some oil mixtures are incompatible and result in the

formation of varnishes, shellacs or lacquers which may be insoluble.

NOTE:

Always specify PRO-TEC oil for use at all ambient

temperatures above -23°C.

Summary of Contents for 7/53

Page 2: ......

Page 4: ......

Page 11: ...DECALS 7 7 53 Engine oil drain...

Page 15: ...GENERAL INFORMATION 11 7 53 7 53 FIXED HEIGHT RUNNING GEAR 7 53 VARIABLE HEIGHT RUNNING GEAR...

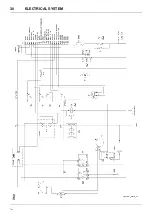

Page 34: ...30 ELECTRICAL SYSTEM 7 53 7 53...

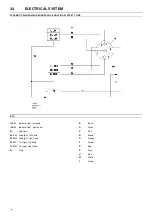

Page 36: ...32 ELECTRICAL SYSTEM 7 53 7 53...

Page 44: ...40 OPTIONS 7 53 WATER SEPARATOR MAINTENANCE FIGURE 4 FIGURE 5 FIGURE 1 FIGURE 2 FIGURE 3...

Page 58: ......

Page 59: ......

Page 60: ......