MAINTENANCE

29

7/53

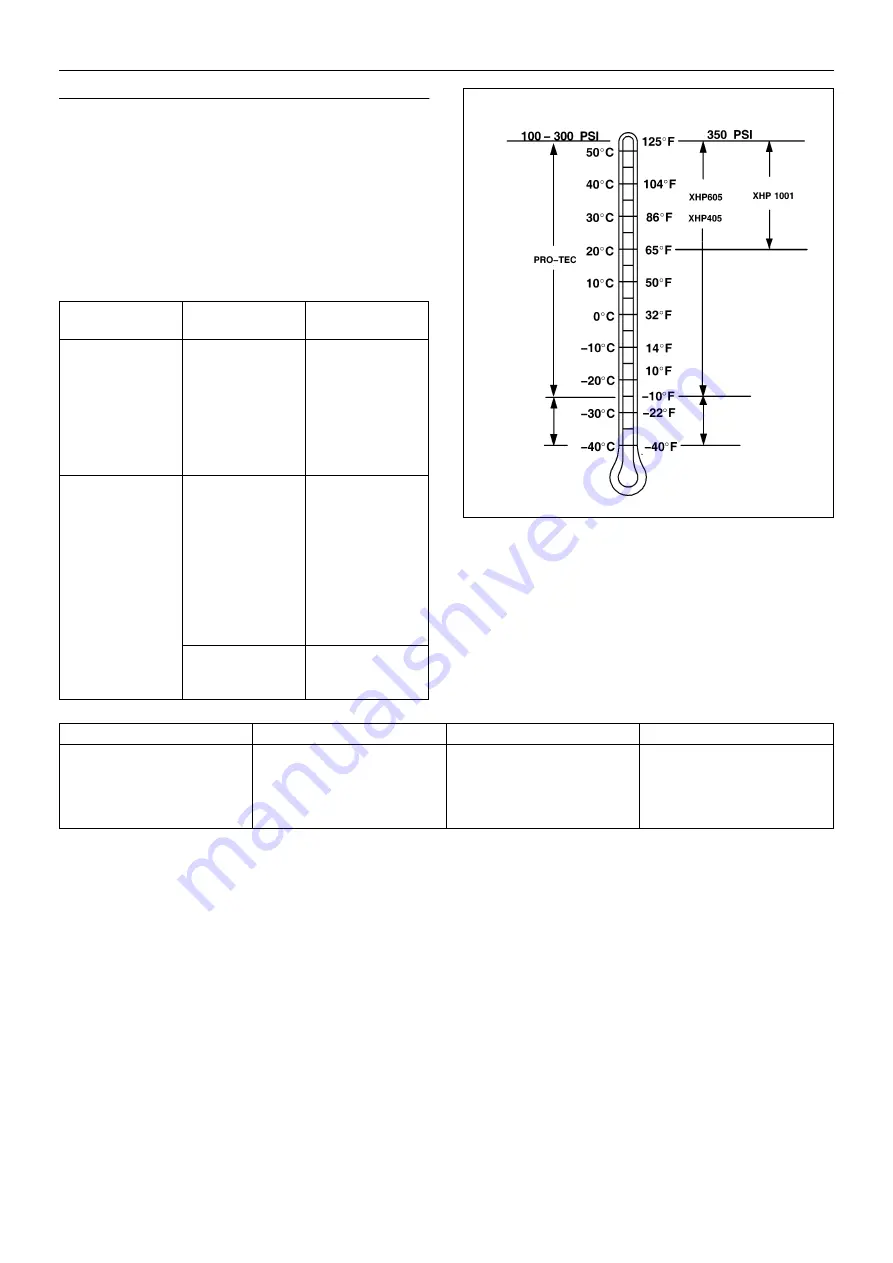

COMPRESSOR LUBRICATION

Portable Compressor Fluid Chart

Refer to these charts for correct compressor fluid required. Note that

the selection of fluid is dependent on the design operating pressure of

the machine and the ambient temperature expected to be encountered

before the next oil change.

Note: Fluids listed as “preferred” are required for extended

warranty.

Compressor oil carryover (oil consumption) may be greater with

the use of alternative fluids.

Preferred Doosan Fluids - Use of these fluids with original Doosan

branded filters can extend airend warranty. Refer to operator’s manual

warranty section for details or contact your Portable Power

representative.

Design Operating

Pressure

Ambient

Temperature

Specification

100 psi to 300 psi

(7 bar to 21 bar)

-10

°

F to 125

°

F

(-23

°

C to 52

°

C)

Preferred:

PRO-TEC

Alternate:

ISO Viscosity Grade

46 with rust and

oxidisation inhibitors,

designed for air

compressor service.

350 psi

(24 bar)

-10

°

F to 125

°

F

(-23

°

C to 52

°

C)

Preferred:

XHP 605

Alternate:

XHP 405

ISO Viscosity Grade

68 Group 3 or 5 with

rust and oxidisation

inhibitors, designed

for air compressor

service.

65

°

F to 125

°

F

(18

°

C to 52

°

C)

Preferred:

XHP 605

XHP 1001

RATED OPERATING PRESSURE

consult factory

consult

factory

Doosan Preferred Fluids

19.0 Litre

208.2 Litre

836 Litre

PRO-TEC

89292973

89292981

22082598

XHP 605

22252076

22252050

22252068

XHP 1001

35612738

35300516

-

XHP 405

22252126

22252100

22252118

Summary of Contents for 7/53

Page 2: ......

Page 4: ......

Page 11: ...DECALS 7 7 53 Engine oil drain...

Page 15: ...GENERAL INFORMATION 11 7 53 7 53 FIXED HEIGHT RUNNING GEAR 7 53 VARIABLE HEIGHT RUNNING GEAR...

Page 34: ...30 ELECTRICAL SYSTEM 7 53 7 53...

Page 36: ...32 ELECTRICAL SYSTEM 7 53 7 53...

Page 44: ...40 OPTIONS 7 53 WATER SEPARATOR MAINTENANCE FIGURE 4 FIGURE 5 FIGURE 1 FIGURE 2 FIGURE 3...

Page 58: ......

Page 59: ......

Page 60: ......